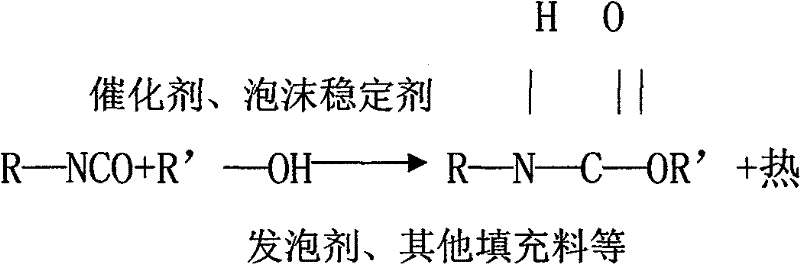

Formula of cold curing foam and forming technique

A technology of foam plastics and molding methods, which is applied in the field of polyurethane foaming, can solve problems affecting the performance of seat cushions, collapse, and low reactivity, and achieve the effects of low cost, low manufacturing temperature, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

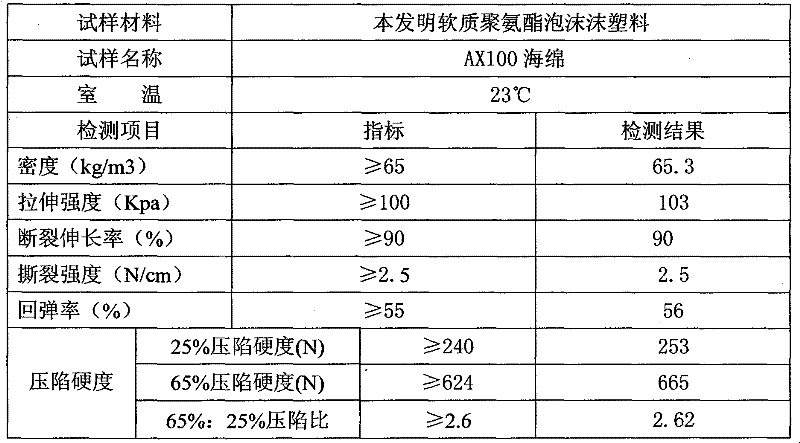

Examples

Embodiment 1

[0014] Cold curing foam is composed of two components, white material and black material, and is a kind of polyurethane foam material formed by the mutual reaction of black material and white material. The white material component is composed of the following raw materials in weight ratio: polyether 3628: 40%, polyether 330N: 25%, water: 2.8%, catalyst 8134: 0.9%, crosslinking agent 2186: 1.9%, triethanolamine: 0.6%, silicone oil 8715: 0.3%, silicone oil 10366: 0.1%, catalyst A-1: 0.05%.; the black material component is composed of the following raw materials by weight ratio: TDI (i.e. toluene diisocyanate): 45%, MDI (i.e. Polyphenyl polymethyl polyisocyanate): 55%.

[0015] Proportion the above-mentioned white material and black material components according to the weight ratio of 100:42. Specifically, the white material and the black material are respectively prepared in the two reaction tanks of the white material and the black material of the high-pressure foaming machin...

Embodiment 2

[0017] Cold curing foam is composed of two components, white material and black material, and is a kind of polyurethane foam material formed by the mutual reaction of black material and white material. When preparing, the white material component is composed of the following raw materials in weight ratio: polyether 3628: 45%, polyether 330N: 35%, water: 2.9%, catalyst 8134: 0.95%, crosslinking agent 2186: 2%, triethanolamine: 0.7%, Silicone Oil 8715: 0.4%, Silicone Oil 10366: 0.2%, Catalyst A-1: 0.06%.; The black material component is composed of the following raw materials by weight ratio: TDI: 48%, MDI: 52%.

[0018] Proportion the above-mentioned white material and black material components according to the weight ratio of 100:45. Specifically, the white material and the black material are respectively prepared in the two reaction tanks of the white material and the black material of the high-pressure foaming machine. Stir for more than 60 minutes, and stir for black mate...

Embodiment 3

[0020] Cold curing foam is composed of two components, white material and black material, and is a kind of polyurethane foam material formed by the mutual reaction of black material and white material. When preparing, the white material component is composed of the following raw materials in weight ratio: polyether 3628: 68%, polyether 330N: 53%, water: 3.0%, catalyst 8134: 1.0%, crosslinking agent 2186: 2.1%, triethanolamine: 0.8%, Silicone Oil 8715: 0.5%, Silicone Oil 10366: 0.3%, Catalyst A-1: 0.1%.; The black material component is composed of the following raw materials by weight ratio: TDI: 55%, MDI: 45%.

[0021] Proportion the above-mentioned white material and black material components according to the weight ratio of 100:48. Specifically, the white material and the black material are respectively prepared in the two reaction tanks of the white material and the black material of the high-pressure foaming machine, and the white material and the black material are prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com