A kind of preparation method of polyether polyol with low degree of unsaturation, high activity and high molecular weight

A polyether polyol and high molecular weight technology is applied in the field of preparation of low unsaturation, high activity and high molecular weight polyether polyol, which can solve the problem of not being able to satisfy low unsaturation, high molecular weight and high activity at the same time, and achieve low unsaturation, high molecular weight and high activity. The effect of unsaturation value, uniform length and uniform distribution of EO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

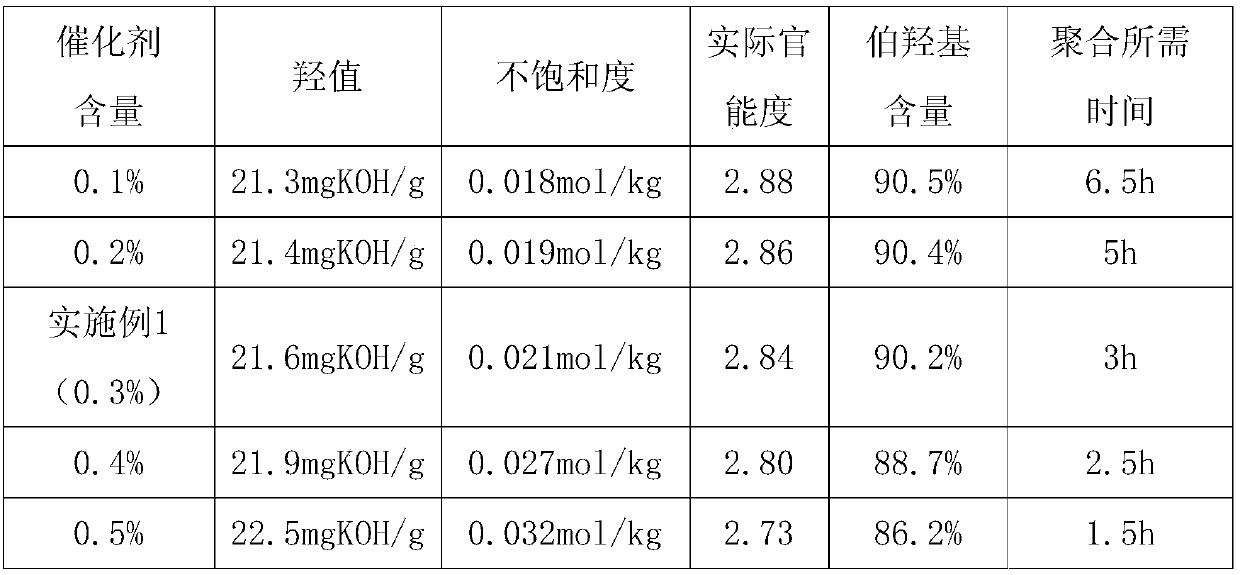

Examples

Embodiment 1

[0028] (1) Add 13.8g of glycerin and 3.22g of cesium hydroxide into the reaction kettle, replace the air in the kettle with nitrogen three times, then raise the temperature to 110-115°C, and keep the temperature for dehydration for 1h under the vacuum degree ≥-0.098MPa. Then 1062g of propylene oxide was added dropwise for reaction, the reaction temperature was controlled to be 110-115° C., and the pressure was less than 0.4 MPa. After the reaction of propylene oxide is completed, slowly add 150g of ethylene oxide dropwise, control the reaction temperature to 110-115°C, and the pressure to be less than 0.4MPa. After the pressure remains constant, the residual monomer is removed in a vacuum. Cool down to 50°C and discharge to obtain 1225g crude polyether polyol.

[0029] (2) Move the crude polyether polyol obtained above to a 2L four-neck flask, add 62g of deionized water and stir for 10 minutes at a temperature of 50°C, add 8g of phosphoric acid for neutralization for 20 minute...

Embodiment 2

[0032] (1) Add 15.2g of propylene glycol and 3.65g of cesium hydroxide to the reaction kettle, replace the air in the kettle with nitrogen three times, then raise the temperature to 100-105°C, and keep the temperature for dehydration for 1h under vacuum degree ≥-0.098MPa. Then 1200g of propylene oxide is added dropwise to react, the reaction temperature is controlled to be 110-115° C., and the pressure is less than 0.4 MPa. After the reaction of propylene oxide is finished, slowly add 105g of ethylene oxide dropwise, control the reaction temperature to 110-115°C, and the pressure to be less than 0.4MPa. After the pressure remains constant, the residual monomer is removed in vacuum. Cool down to 50°C and discharge to obtain 1320 g of crude polyether polyol.

[0033] (2) Move the crude polyether polyol obtained above to a 2L four-necked flask, add 66g of deionized water and stir for 10 minutes at a temperature of 50°C, add 8.4g of phosphoric acid for neutralization for 20 minute...

Embodiment 3

[0036](1) Add 18.8g of trimethylolpropane and 3.83g of cesium hydroxide into the reaction kettle, replace the air in the kettle with nitrogen three times, then raise the temperature to 110-115°C, and dehydrate under vacuum ≥-0.098MPa 1h, then dropwise add 1260g propylene oxide to react, control the reaction temperature to be 110-115°C, and the pressure is less than 0.4MPa. 115°C, the pressure is less than 0.4MPa, and the residual monomer is vacuumed out after the pressure remains constant. Cool down to 50°C and discharge to obtain 1363g of crude polyether polyol.

[0037] (2) Move the crude polyether polyol obtained above to a 2L four-neck flask, add 68g of deionized water and stir for 10 minutes at a temperature of 50°C, add 8.8g of phosphoric acid for neutralization for 20 minutes, add 11g of polyether refined adsorbent for adsorption For 10 minutes, the adsorption temperature is 60-70°C, then the temperature is raised to 110-115°C, and at a vacuum degree ≥ -0.098MPa, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com