Preparation method of high-activity polyether polyol

A high-activity polyether and polyol technology, which is applied in the field of preparation of high-activity polyether polyols, can solve the problems of many side reactions and low activity, and achieve the effect of simple method, high polymerization activity and few side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

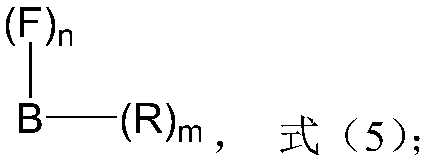

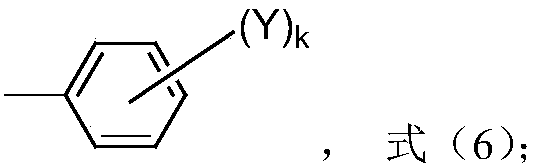

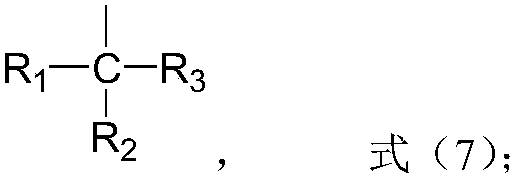

Method used

Image

Examples

Embodiment 1

[0045] Add 400 g of difunctional polyether polyol GEP-204 with a molecular weight of 400 and 0.06 g of a bimetallic catalyst in a 3L autoclave equipped with a pressure and temperature gauge, a stirring device and a raw material feed port. After nitrogen replacement, the temperature was raised to 130° C., and 800 g of propylene oxide was continuously added over 1 hour. After the feeding of propylene oxide was completed, the mixture was aged for 1 hour, and the low-boiling fraction in the system was extracted with a vacuum pump, then the temperature was lowered to 60° C., and 0.06 g of tris(pentafluorophenyl)boron was added. After 1 hour, 950 g of propylene oxide was added continuously, aged for 1 hour, the low boiling point fraction in the system was extracted with a vacuum pump, 100 g of water was added, stirred for 5 hours, water was removed, and 1990 g of polymer was obtained from discharge. The polymer has a hydroxyl value of 56.3 mgKOH / g, a molecular weight distribution of...

Embodiment 2

[0047] Add 400 g of difunctional polyether polyol GEP-204 with a molecular weight of 400 and 0.06 g of a bimetallic catalyst in a 3L autoclave equipped with a pressure and temperature gauge, a stirring device and a raw material feed port. After nitrogen replacement, the temperature was raised to 130° C., and 1200 g of propylene oxide was continuously added over 1 hour. After the feeding of propylene oxide was completed, the mixture was aged for 1 hour, and the low-boiling fraction in the system was extracted with a vacuum pump, then the temperature was lowered to 60° C., and 0.06 g of tris(pentafluorophenyl)boron was added. After 1 hour, 480 g of propylene oxide was added continuously, and matured for 1 hour. The low boiling point fraction in the system was extracted with a vacuum pump, 100 g of water was added, stirred for 5 hours, water was removed, and 1990 g of polymer was discharged. The polymer has a hydroxyl value of 56.3 mgKOH / g, a molecular weight distribution of 1.07...

Embodiment 3

[0049] Add 200 g of difunctional polyether polyol GEP-204 with a molecular weight of 400 and 0.06 g of a bimetallic catalyst in a 3 L autoclave equipped with a pressure and temperature gauge, a stirring device and a raw material feed port. After nitrogen replacement, the temperature was raised to 130° C., and 1400 g of propylene oxide was continuously added over 1 hour. After the feeding of propylene oxide was completed, the mixture was aged for 1 hour, and the low-boiling fraction in the system was extracted with a vacuum pump, then the temperature was lowered to 60° C., and 0.06 g of tris(pentafluorophenyl)boron was added. After 1 hour, 500 g of propylene oxide was added continuously, aged for 1 hour, the low boiling point fraction in the system was extracted with a vacuum pump, 100 g of water was added, stirred for 5 hours, water was removed, and 1993 g of polymer was obtained from discharge. The hydroxyl value of the polymer is 28.4 mgKOH / g, the molecular weight distributi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com