Allyl alcohol methyl terminated polyether as well as preparation method and application thereof

A technology of allyl alcohol methyl capping and allyl alcohol polyether, which is applied in the directions of ether preparation, botanical equipment and method, application, etc., and can solve the problem of wide molecular weight distribution and primary hydroxyl content of allyl alcohol methyl capped polyether. It can achieve the effect of high double bond retention rate, narrow molecular weight distribution and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

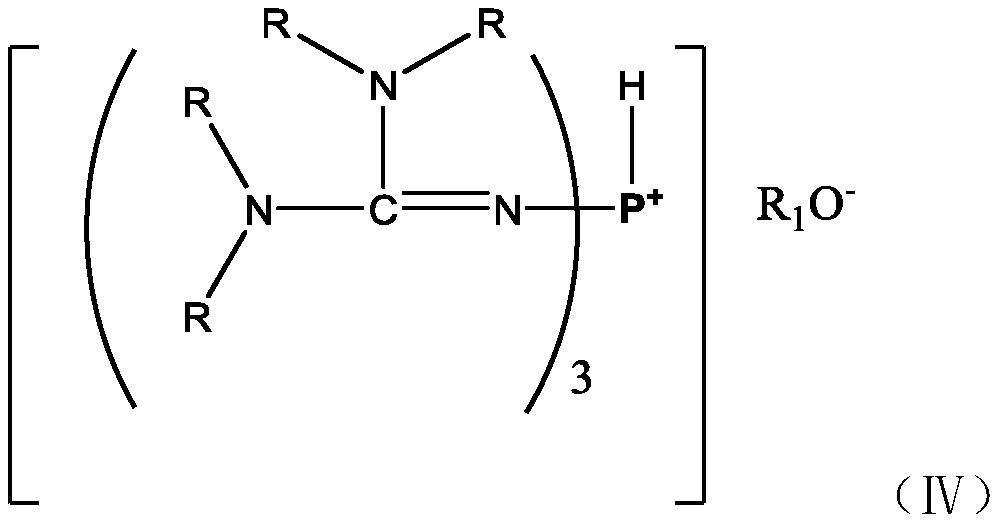

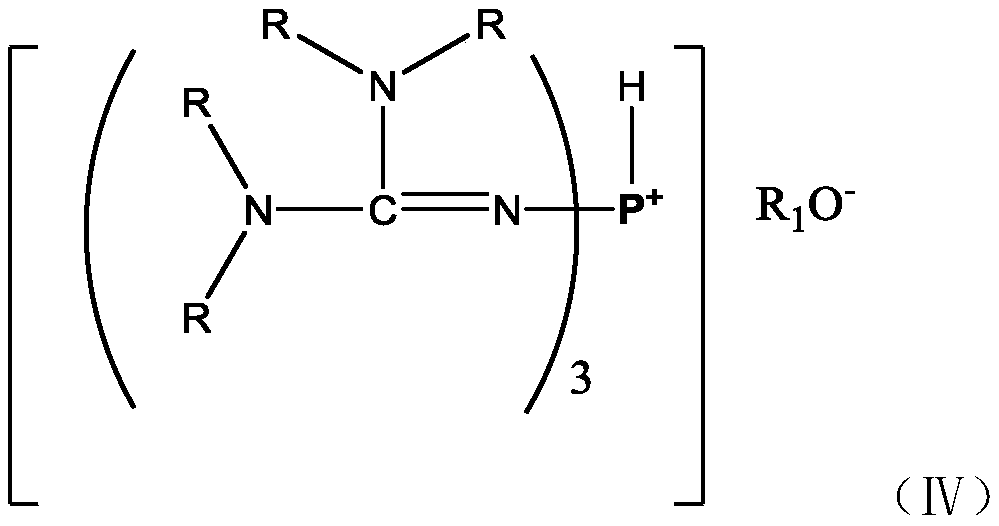

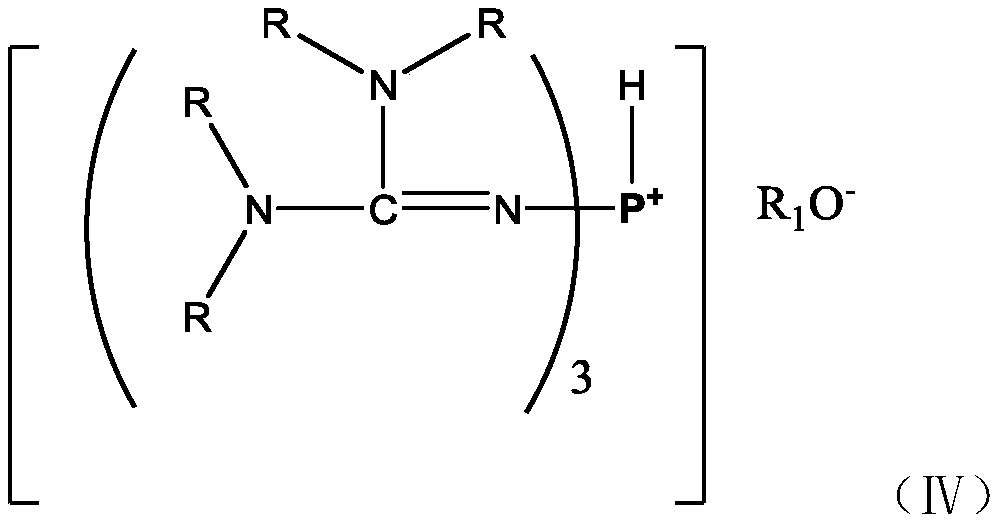

[0035] 1, add allyl alcohol 100g in 5L autoclave, adopt the phosphazene catalyst of general formula (IV) in the present invention (wherein R is methyl, R 1 is methyl) 0.82g, feed 207g of propylene oxide, the reaction temperature is 75~85 ℃, nitrogen is replaced 3 times, after adding, ripening until the pressure does not drop, to obtain allyl alcohol polyether material I, the allyl alcohol The polyether material I is shown in step 1 of Table 1;

[0036] 2. Feed 727 g of ethylene oxide, and react material I with ethylene oxide again. The reaction temperature is 90 to 100 ° C, and nitrogen is replaced for 3 times. After adding, it is aged until the pressure does not drop to obtain allyl alcohol polyether material II. , the allyl alcohol polyether material II is shown in step 2 of table 1.

[0037] 3. The allyl alcohol polyether material II of step 2 was put into 102.3 g of solid sodium methoxide, replaced with nitrogen for 3 times, and the stirring was started. Remove methanol ...

Embodiment 2 to 8 and comparative example 1 to 3

[0040] The experiments of Examples 2 to 8 and Comparative Examples 1 to 3 were carried out according to the steps of Example 1, and the only difference was that the types of reaction raw materials, catalyst types, raw material ratios, reaction times and temperatures were different. See Table 1 for details. The product quality of the obtained allyl alcohol methyl-terminated polyether is shown in Table 3.

[0041] The raw material weight percentage of each component in Table 1 Example 1 to Example 5

[0042]

[0043]

[0044] The raw material weight percentage of each component in Table 2 Examples 6 to 8 and Comparative Examples 1 to 3

[0045]

[0046]

[0047]

[0048] Table 3 Quality inspection data of allyl alcohol methyl-terminated polyethers prepared in Examples 1 to 8 and Comparative Examples 1 to 3

[0049] molecular weight Capping rate (%) Double bond retention rate (%) Molecular weight distribution coefficient Example 1 600 98 9...

Embodiment 9

[0056] The allyl alcohol block methyl-terminated refined ether prepared in Example 1 was used to prepare the polyurethane foam stabilizer with the formula, reaction temperature and reaction time shown in Table 4.

[0057] Table 4 prepares the formula of polyurethane foam stabilizer (unit: kg)

[0058]

[0059] The polyurethane foam stabilizer prepared in Example 9 was foamed with the formula of the typical free-rising polyurethane foam shown in Table 5 to prepare a polyurethane foam, and the obtained polyurethane foam was soft to the touch, and the openings were fine and uniform.

[0060] Table 5 Typical formulations of free-rising polyurethane foams

[0061] Unit: parts by weight

[0062] raw material Recipe 1 Polyether polyol (CHE-2045) 99 Polyurethane foam stabilizer in embodiment 9 1 h 2 o

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com