Fast-curing slow-rebound acrylic foam as well as preparation method and application thereof

An acrylic foam and rapid curing technology, which is applied in the field of foam materials, can solve the problems of slow curing speed, high density and slow resilience of acrylic foam shock-absorbing foam, and achieve small compression residual deformation, long operation time, The effect of good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

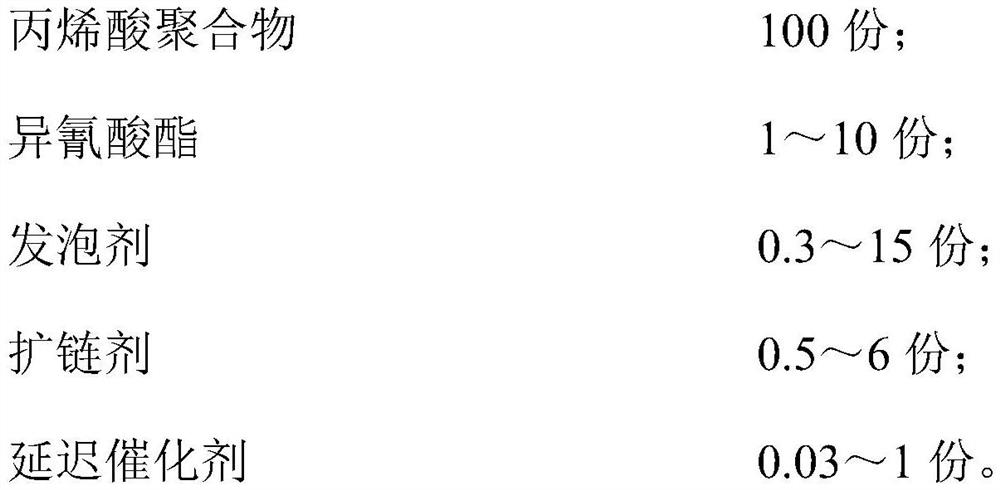

[0053] In this embodiment, a fast-curing and slow-rebound acrylic foam is provided, and the preparation raw materials of the fast-curing and slow-rebound acrylic foam include the following components in parts by weight:

[0054]

[0055]

[0056] Among them, the number-average molecular weight of the acrylic polymer (brand name: Yake Chemical YZ-H305) is 4000, the hydroxyl value is 54mgKOH / g, and the solid content is 40%; the isocyanate is toluene diisocyanate; the blowing agent is azobisisobutyl Nitrile; chain extender is 1,4-butanediol; delayed catalyst is (acetylacetonate) dibutyltin dilaurate.

[0057] The preparation method comprises the following steps:

[0058] (1) The acrylic acid polymer, delayed catalyst, chain extender, foaming agent and organic solvent were mixed and dispersed at high speed for 40 minutes, and then added with isocyanate, mixed and dispersed at high speed for 30 minutes to obtain a mixed solution;

[0059] (2) Coating the mixed solution on th...

Embodiment 2

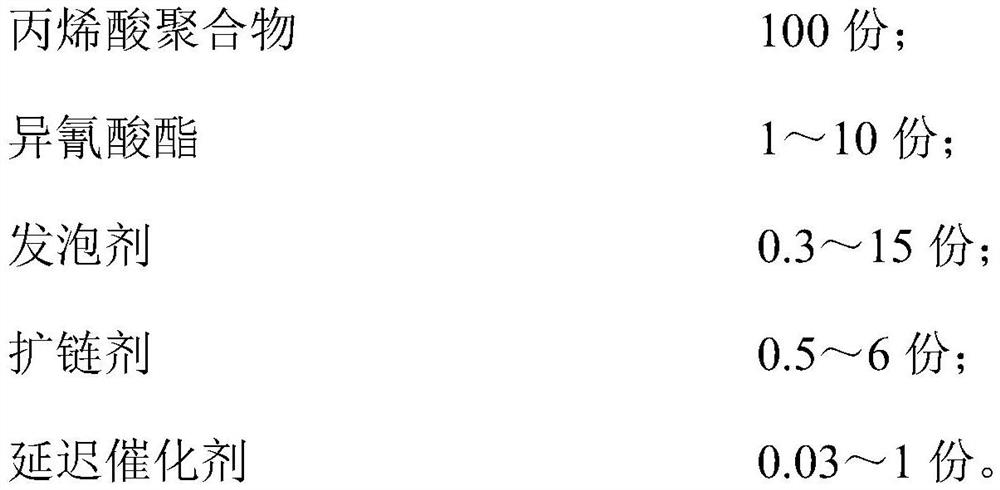

[0063] In this embodiment, a fast-curing and slow-rebound acrylic foam is provided, and the preparation raw materials of the fast-curing and slow-rebound acrylic foam include the following components in parts by weight:

[0064]

[0065]

[0066] Among them, the number-average molecular weight of the acrylic polymer (brand name: Yake Chemical YZ-H706) is 5000, the hydroxyl value is 70mgKOH / g, and the solid content is 60%; the isocyanate is isophorone diisocyanate; the blowing agent is p-toluene Sulfonyl hydrazide; chain extender is 1,6-hexanediol; delayed catalyst is (acetylacetonate) triethylenediamine.

[0067] The preparation method comprises the following steps:

[0068] (1) Mix, disperse and stir the acrylic polymer, delayed catalyst, chain extender, foaming agent and organic solvent at high speed for 30 minutes, then add isocyanate, mix and disperse and stir at high speed for 60 minutes to obtain a mixed solution;

[0069] (2) Coating the mixed solution on the bas...

Embodiment 3

[0073] In this embodiment, a fast-curing and slow-rebound acrylic foam is provided, and the preparation raw materials of the fast-curing and slow-rebound acrylic foam include the following components in parts by weight:

[0074]

[0075]

[0076] Among them, the number average molecular weight of the acrylic polymer (trade name: Yake Chemical YZ-H638) is 8000, the hydroxyl value is 75mgKOH / g, and the solid content is 60%; the isocyanate is diphenylmethane diisocyanate; Nitropentamethylenetetramine; chain extender is glycerin; delayed catalyst is zinc octanoate (acetylacetonate).

[0077] The preparation method comprises the following steps:

[0078] (1) The acrylic acid polymer, delayed catalyst, chain extender, foaming agent and organic solvent were mixed and dispersed at high speed for 50 minutes, and then added with isocyanate, mixed and dispersed at high speed for 50 minutes to obtain a mixed solution;

[0079] (2) Coating the mixed solution on the base material, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com