Washing machine

A washing machine and laundry technology, which is applied in the field of washing machines, can solve problems such as false detection of foam, and achieve the effect of preventing electrode misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

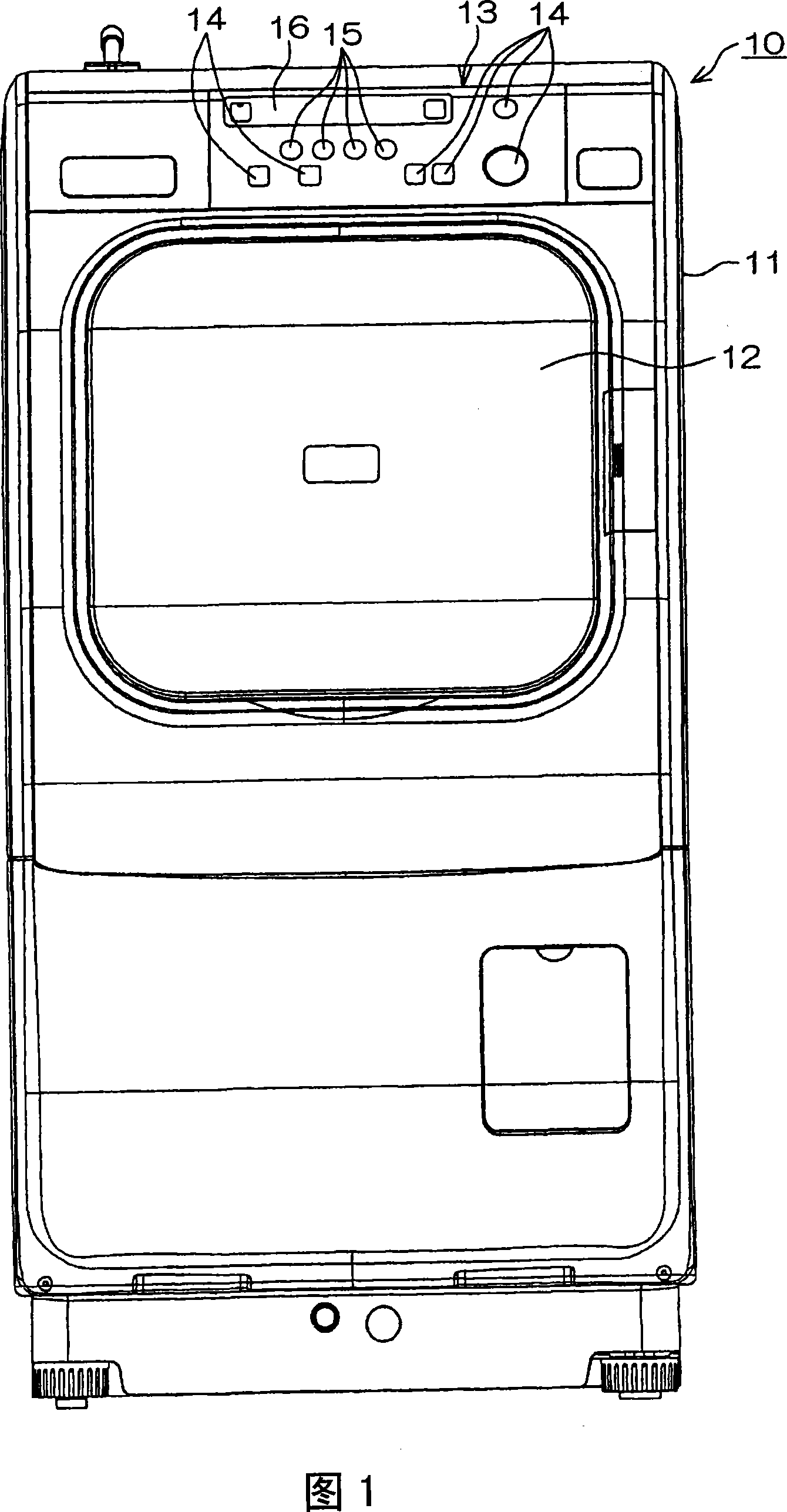

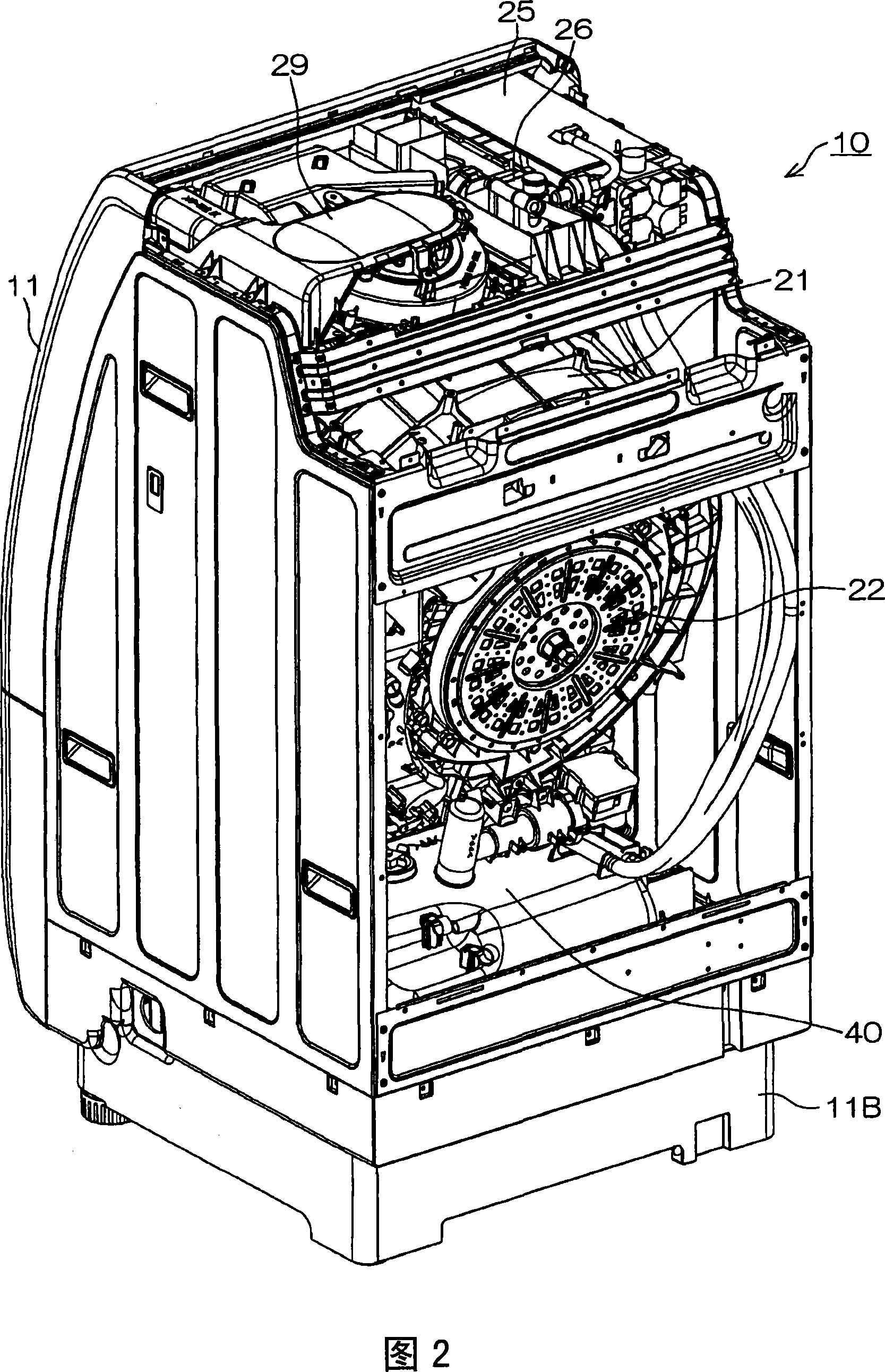

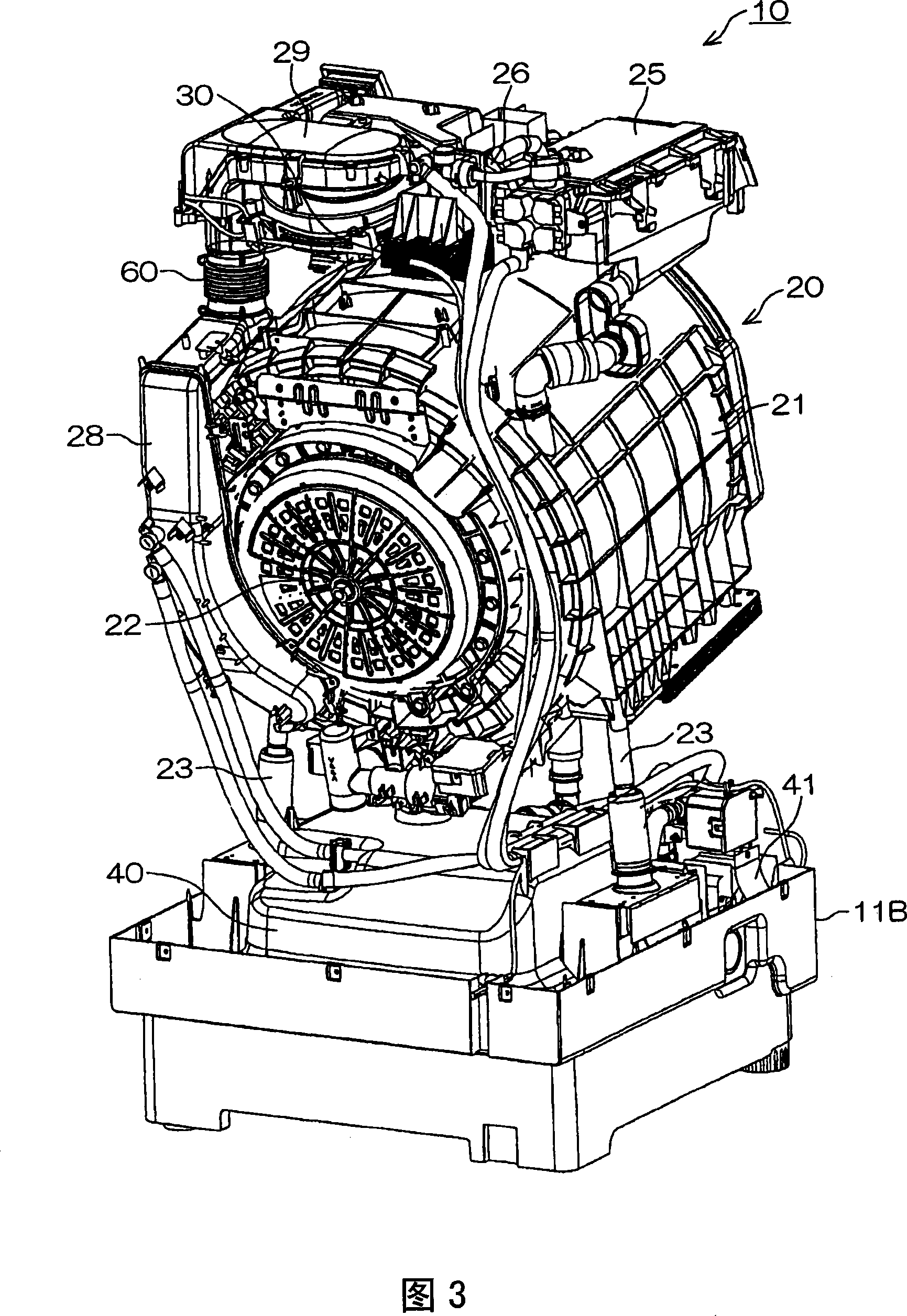

[0044] FIG. 1 is a front view of an electric washing machine 10 according to one embodiment of the present invention. The electric washing machine 10 has a casing 11 that is vertically long and substantially rectangular in front view, constituting its casing. A washing tank (described later) is arranged above the inside of the housing 11, and a water storage tank (described later) is arranged below the inside.

[0045] An opening is formed above the front surface of the casing 11, and an openable and closable door 12 is provided on the opening. The main surface of the door 12 is made of, for example, transparent tempered glass, so that the state of the laundry in the washing tub inside can be seen clearly.

[0046] An operation / display unit 13 is disposed on the upper front portion of the housing 11 (above the door 12 ). A plurality of operation keys 14 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com