Pile-spraying rotary construction method using tide difference subsection pile-formation

A construction method and technology of rotary grouting piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as grout running, hole collapse, grout leakage, etc., and achieve good technical and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

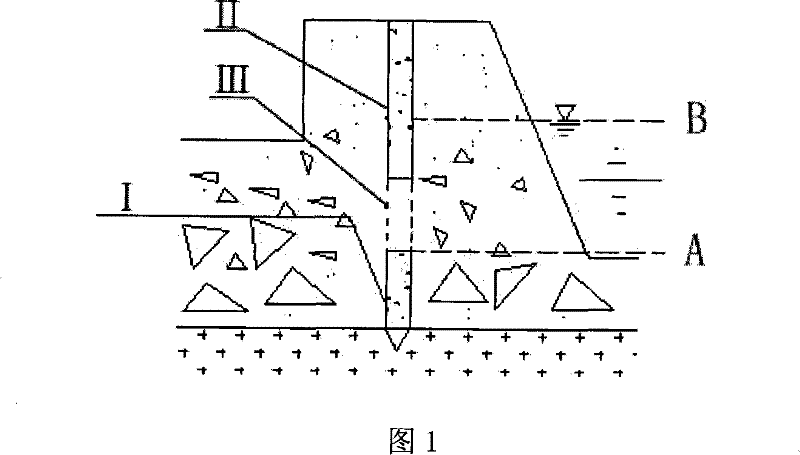

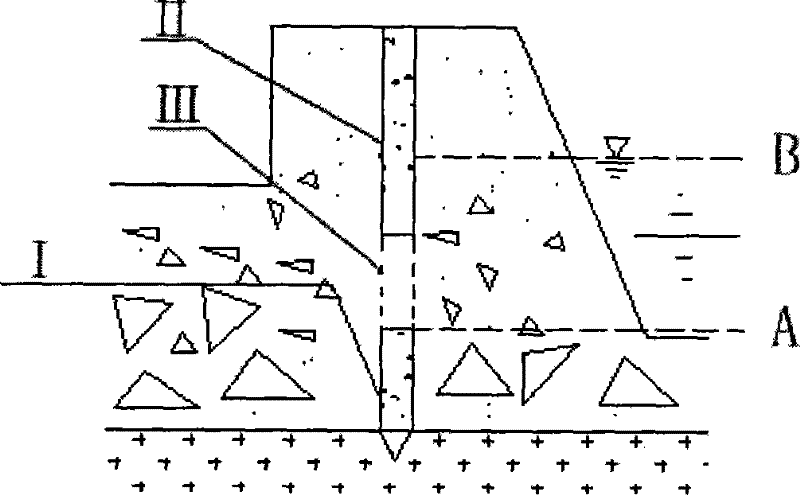

[0011] Please refer to the attached drawing of the instruction manual, a construction method of rotary grouting piles using tidal difference to form piles in sections. The whole pile is divided into 3 sections to complete. Section II piles are also completed by one-time jet spraying; Section III piles between section I piles and section II piles are gradually completed using the time of tide level changes.

[0012] Specific steps are as follows:

[0013] 1) Before the high tide, complete the section I pile at the lowest tide level, and stop the rotary spraying when the high tide water level reaches the rotary spraying position, so as to prevent the cement slurry from being taken away by sea water;

[0014] 2), at this time, adjust the nozzle to the soil layer with poor water permeability in the upper part of the highest tide level, and complete the rotary spraying of the II section pile;

[0015] 3), when the tide level drops below the top of the I section pile, immediately f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com