Internal heat exchanger for automotive air conditioner

A technology for internal heat exchangers and air conditioners, applied to indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve problems such as not being able to ensure sufficient length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

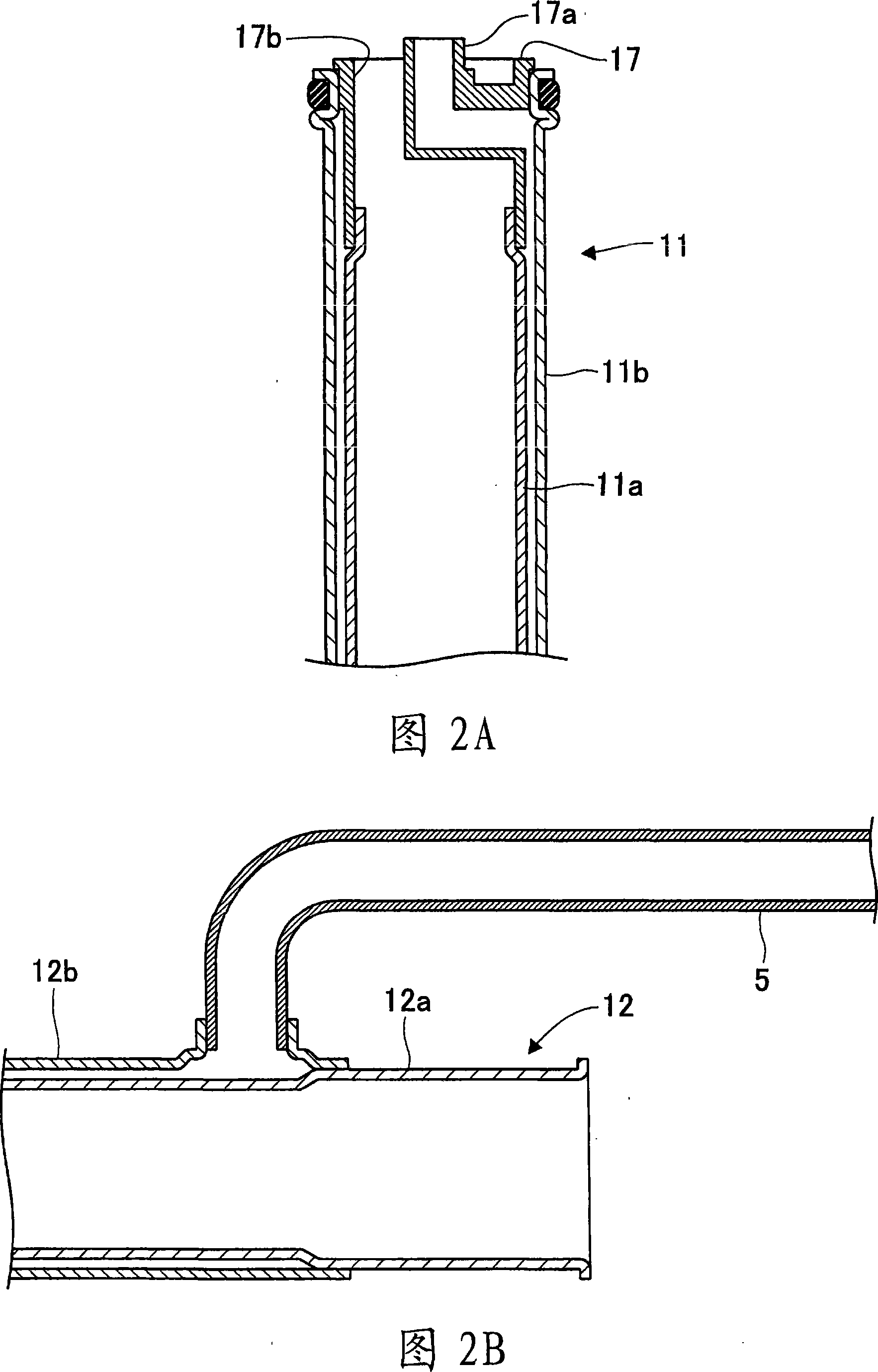

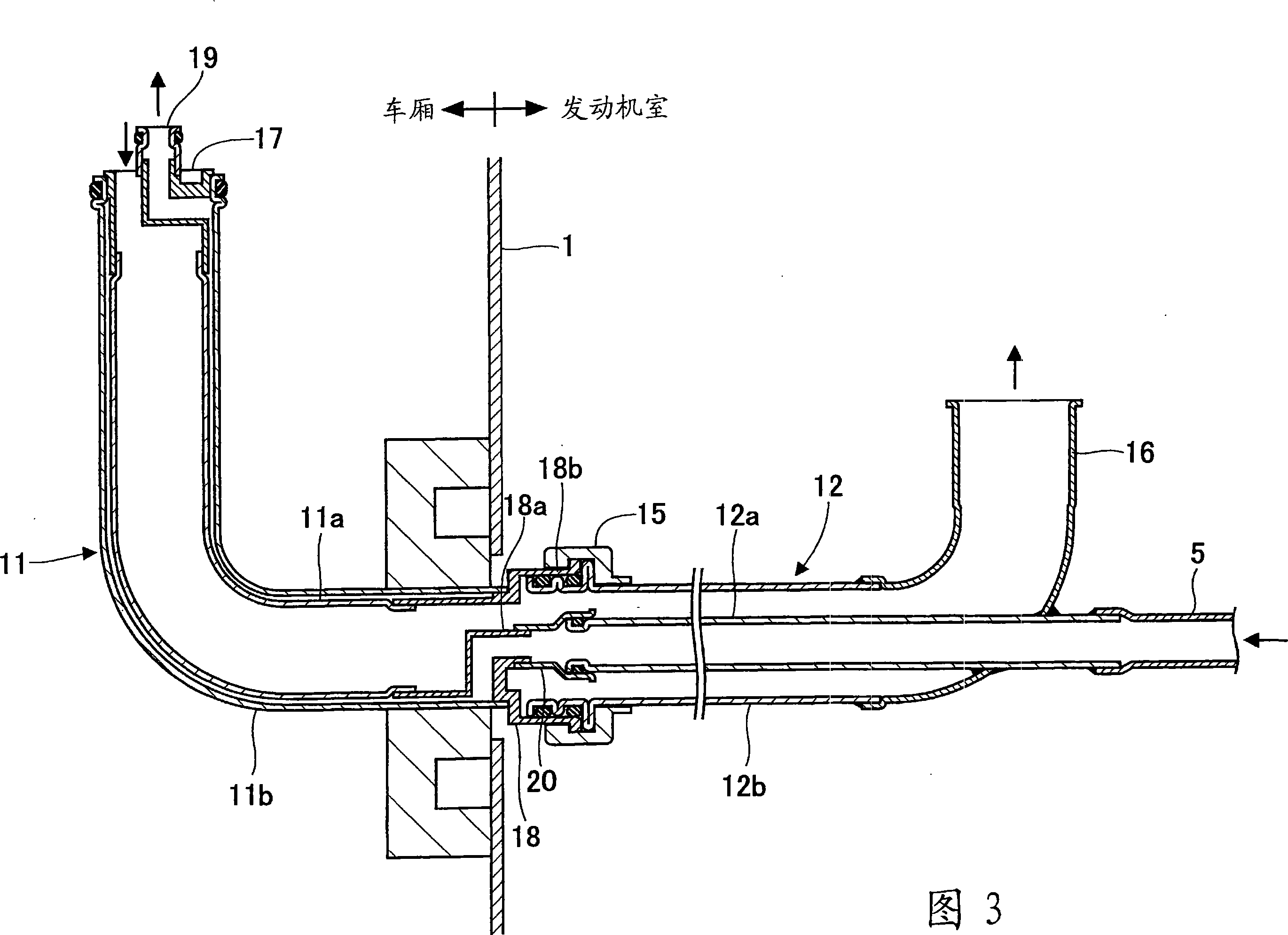

[0014] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings showing preferred embodiments of the invention.

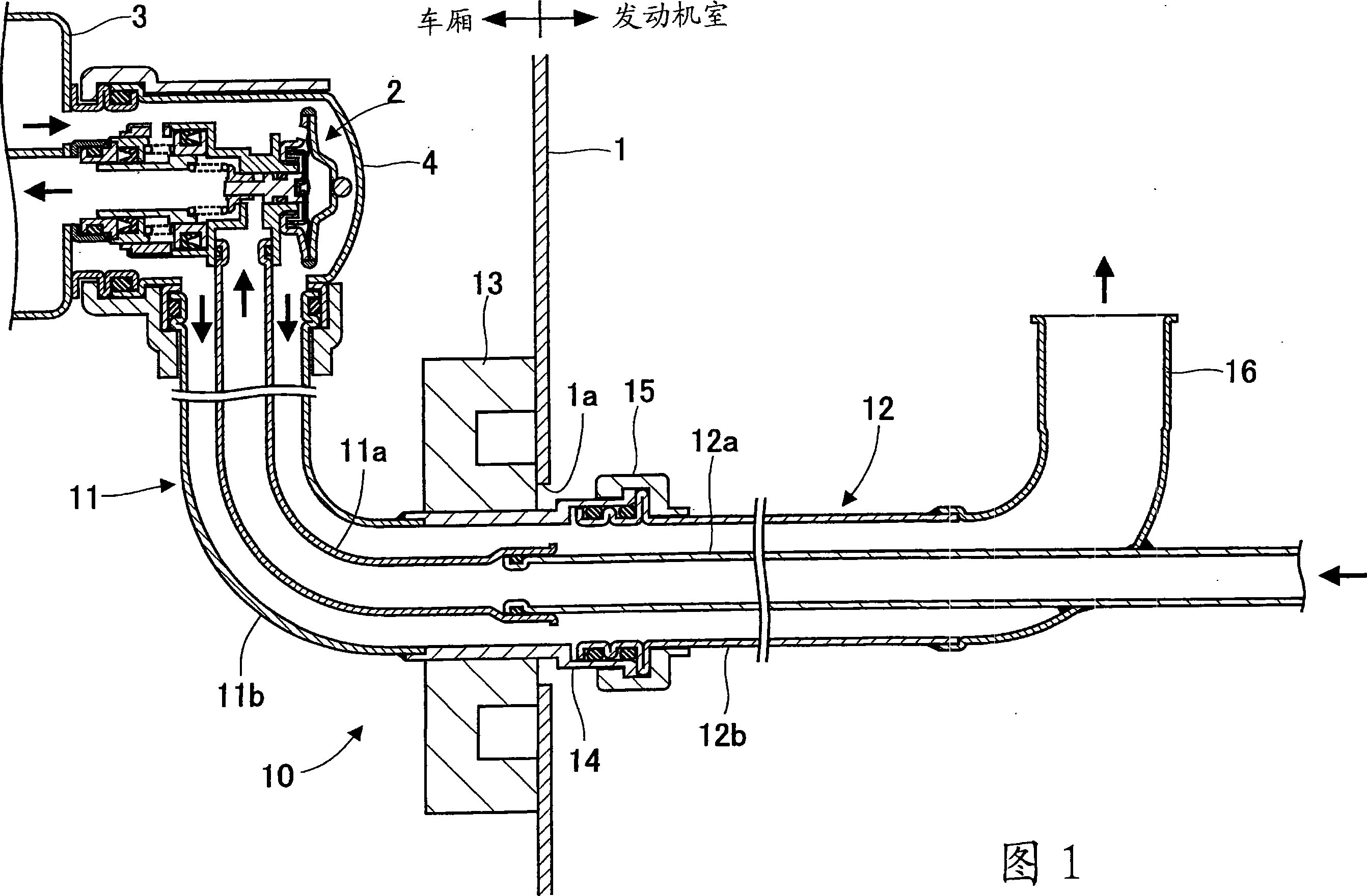

[0015] FIG. 1 is a diagram showing an installation example of an expansion valve and an internal heat exchanger according to a first embodiment of the present invention.

[0016] In the refrigeration cycle of an automobile air conditioner, a compressor, a condenser, and a receiver (all not shown) are arranged in the engine room of the vehicle, and an expansion valve 2 and an evaporator are arranged in the compartment separated from the engine room by a partition wall 1 3. In the illustrated embodiment, the expansion valve 2 is accommodated in a housing 4 mounted on the end face of the evaporator 3 in such a manner as to cover the inlet and outlet of the evaporator 3 . Inside the housing 4 the refrigerant outlet of the expansion valve 2 is connected to the inlet of the evaporator 3 . The expansion valve 2 and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com