Mounting process of three-core cable shrink terminal

A three-core cable and installation process technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of low interface field strength, complex installation process, low electrical and mechanical strength, etc., to achieve high work efficiency and simple installation process. , easy to grasp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

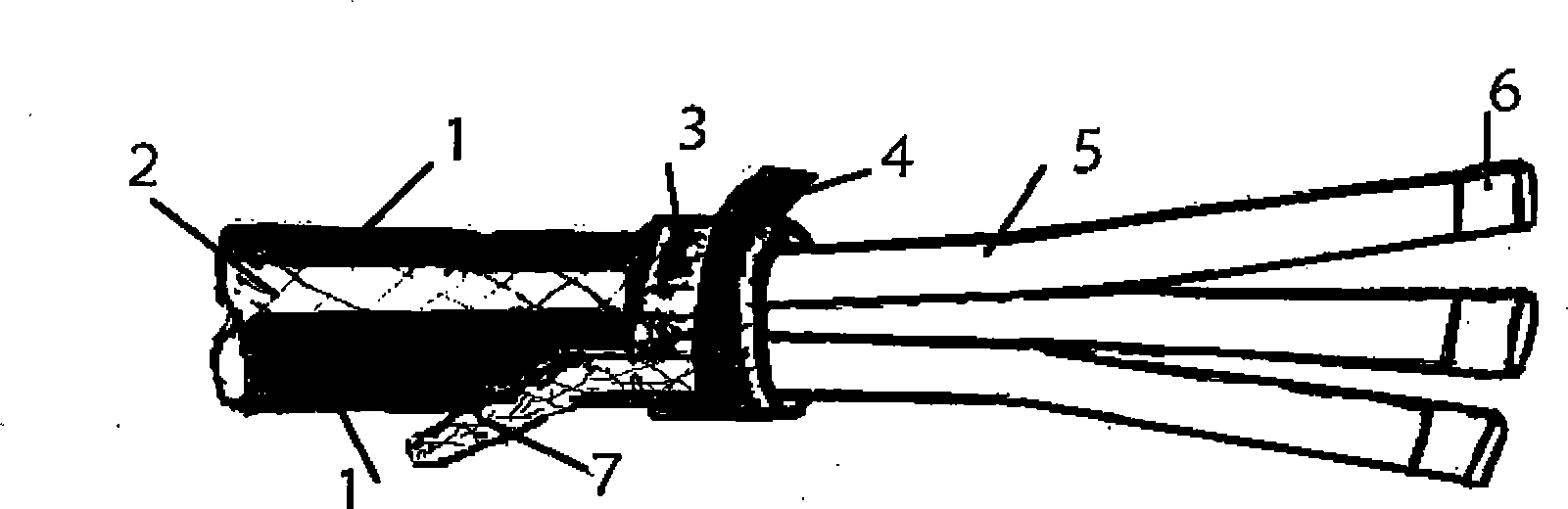

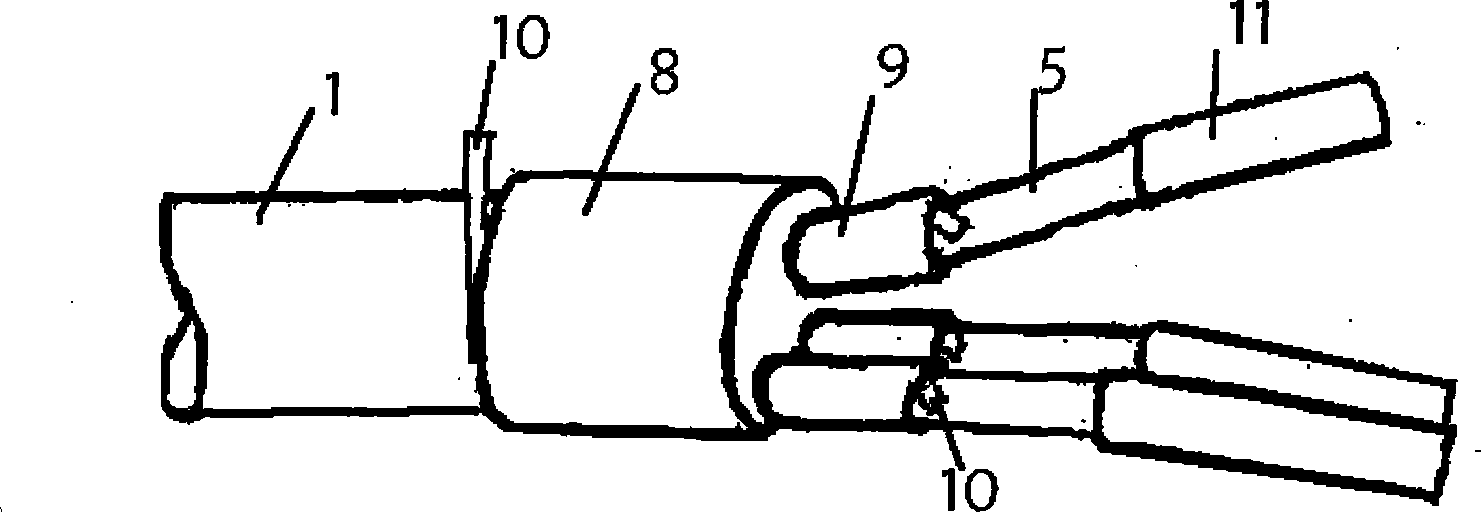

[0020] The invention provides a three-core cable cold-shrink terminal installation process. Below in conjunction with the accompanying drawings, taking the installation process of a 15KV three-core cable cold-shrink terminal as an example, the installation steps of the present invention will be described in detail:

[0021] 1) In order to reduce the impact caused by moisture, pollution or unevenness at the end of the cable, measure the straightened cable from the end of the cable to the back for more than 900mm, and strip the outer sheath 1 of the end to expose three cable cores;

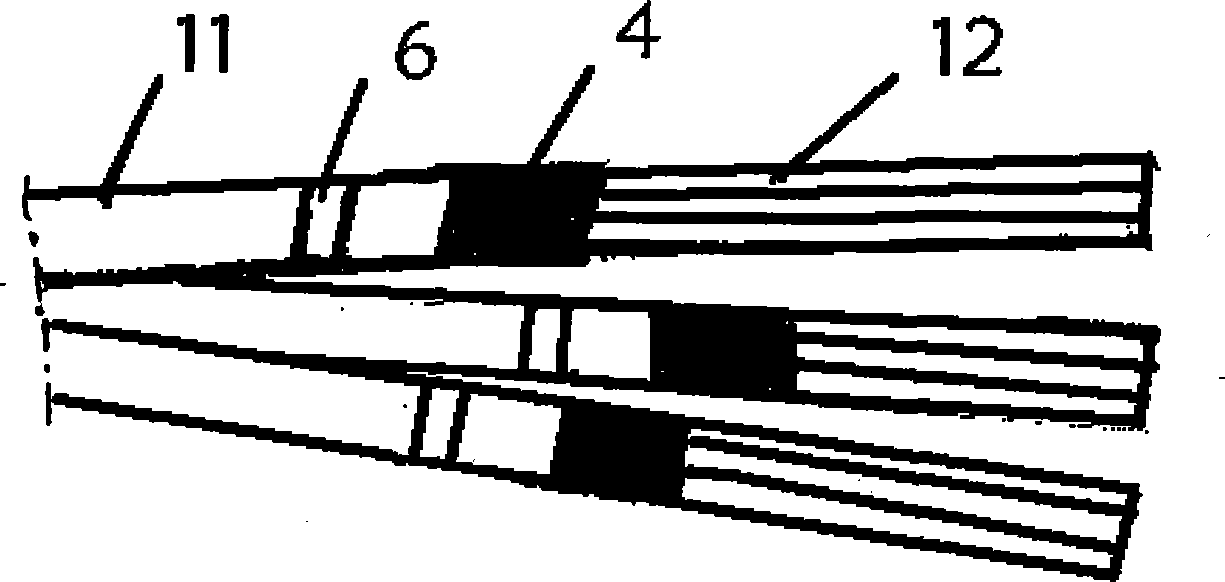

[0022] 2) Take the first constant force spring 3, clamp the ground wire 2 on the steel armor, cut off the steel armor along the upper end of the first constant force spring 3, measure 10mm from the end of the cut steel armor, and then cut off the inner Sheath, be careful not to damage the copper shielding 5, and wrap a circle of PVC red, yellow, and green tapes on the ends of the three cable cores f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com