Jaw crusher and self-travelling crusher

A jaw crusher and crusher technology, which is applied in the direction of motor vehicles, mechanical equipment, screws, etc., can solve the problems of reduced bolt fixing strength, weakened cheek plate installation structure, and shortened bolt life, so as to achieve a firm installation structure and prevent installation. Decrease in strength, effect of preventing abrasion or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] [Outline description of the overall configuration]

[0023] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

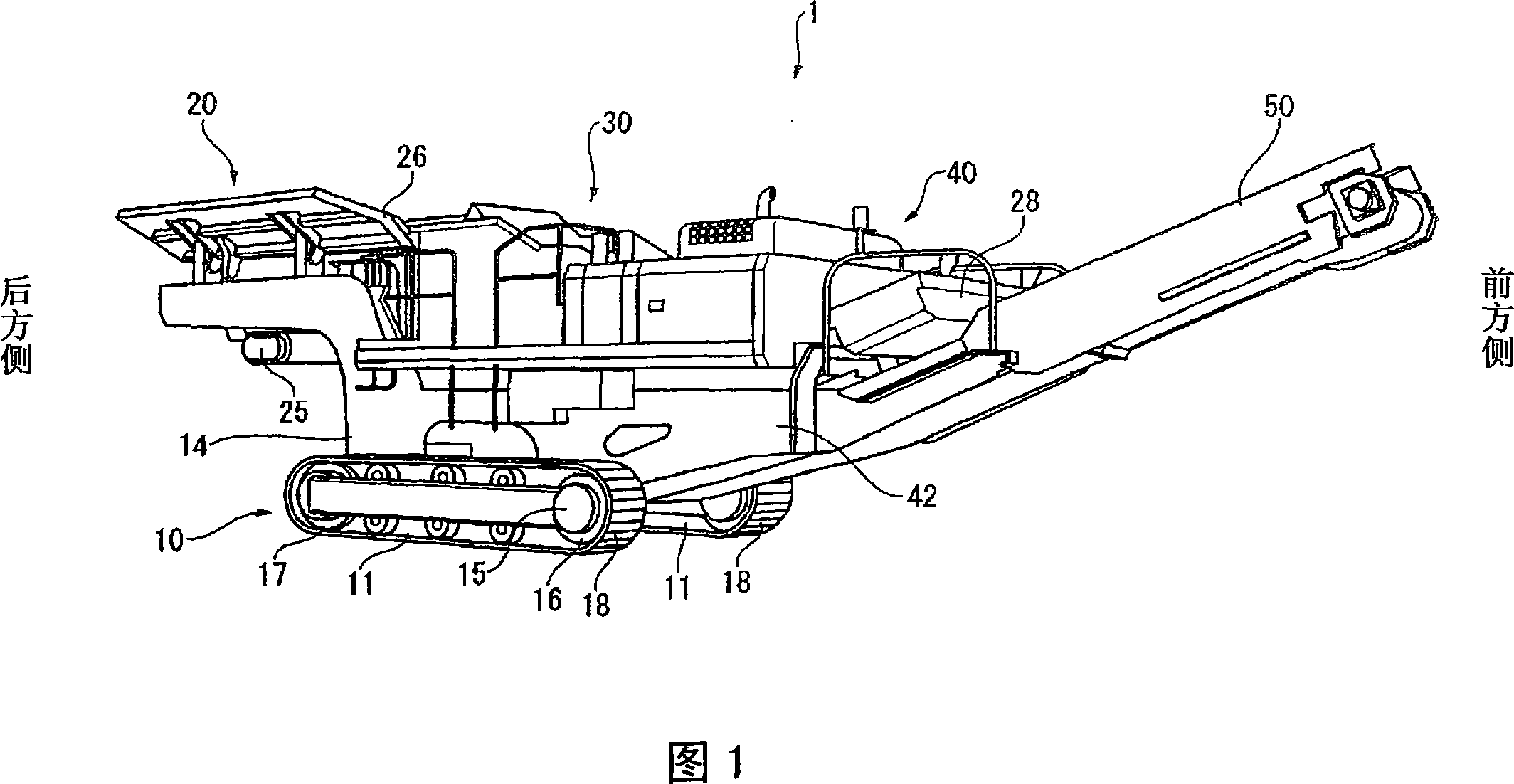

[0024] FIG. 1 is a perspective view showing a self-propelled crusher 1 according to this embodiment. It should be noted that, in this embodiment, for convenience of description, the right side in FIG. 1 is the front side, and the left side is the rear side.

[0025] The self-propelled crusher 1 is composed of a main body unit 10 having a pair of lower traveling bodies 11, a supply unit 20 mounted on the rear side of the main body unit 10 and supplying raw materials, and a jaw type jaw mounted on the front side of the supply unit 20. The crusher 30 , the power unit 40 mounted on the front side of the jaw crusher 30 , and the discharge transport unit 50 extending obliquely forward and upward from between the pair of crawler belts 18 under the main body unit 10 are constituted.

[0026] The main body unit 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com