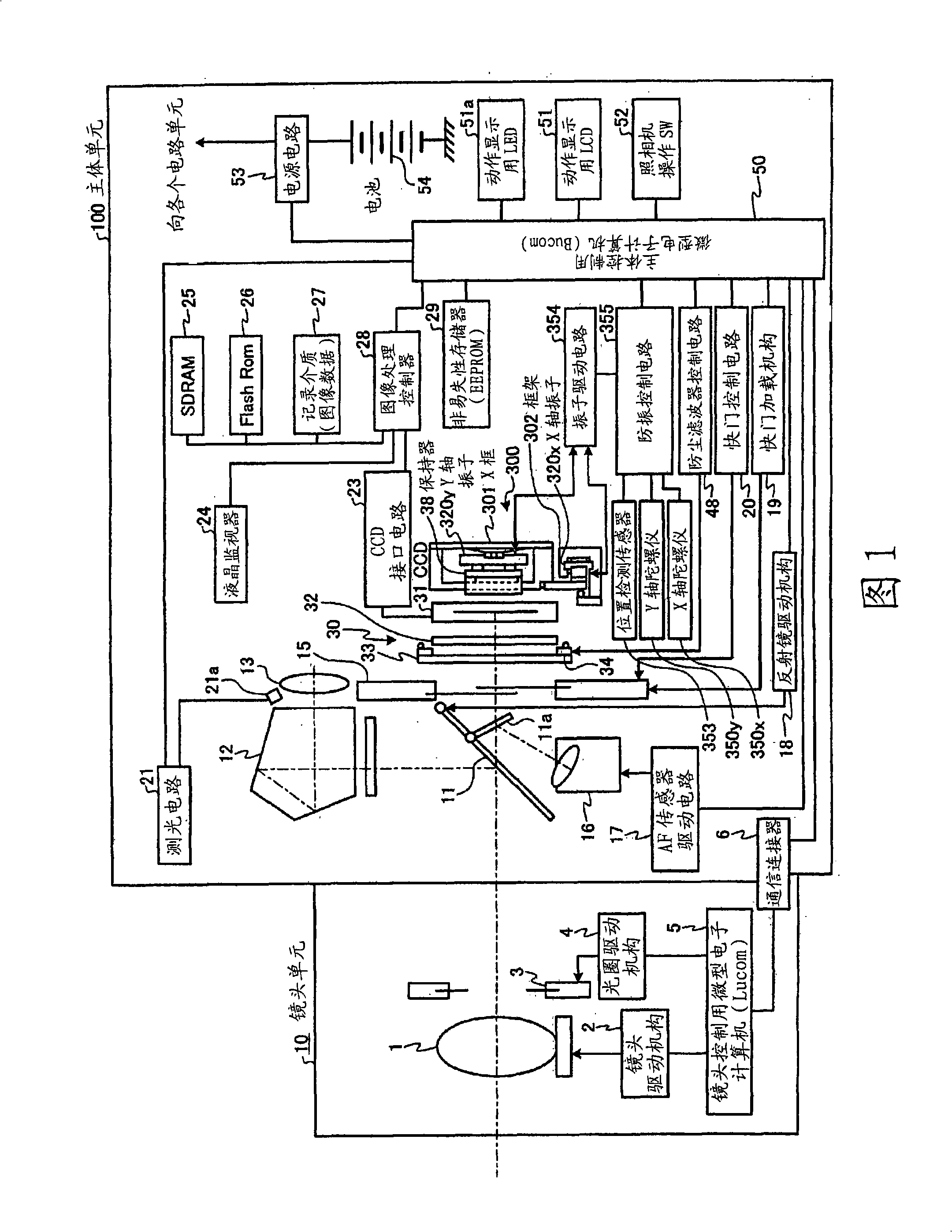

Driving device and imaging device

A technology of driving device and camera device, which is applied in the direction of installation, generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, etc., which can solve the problems of audible sound and inability to completely prevent vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

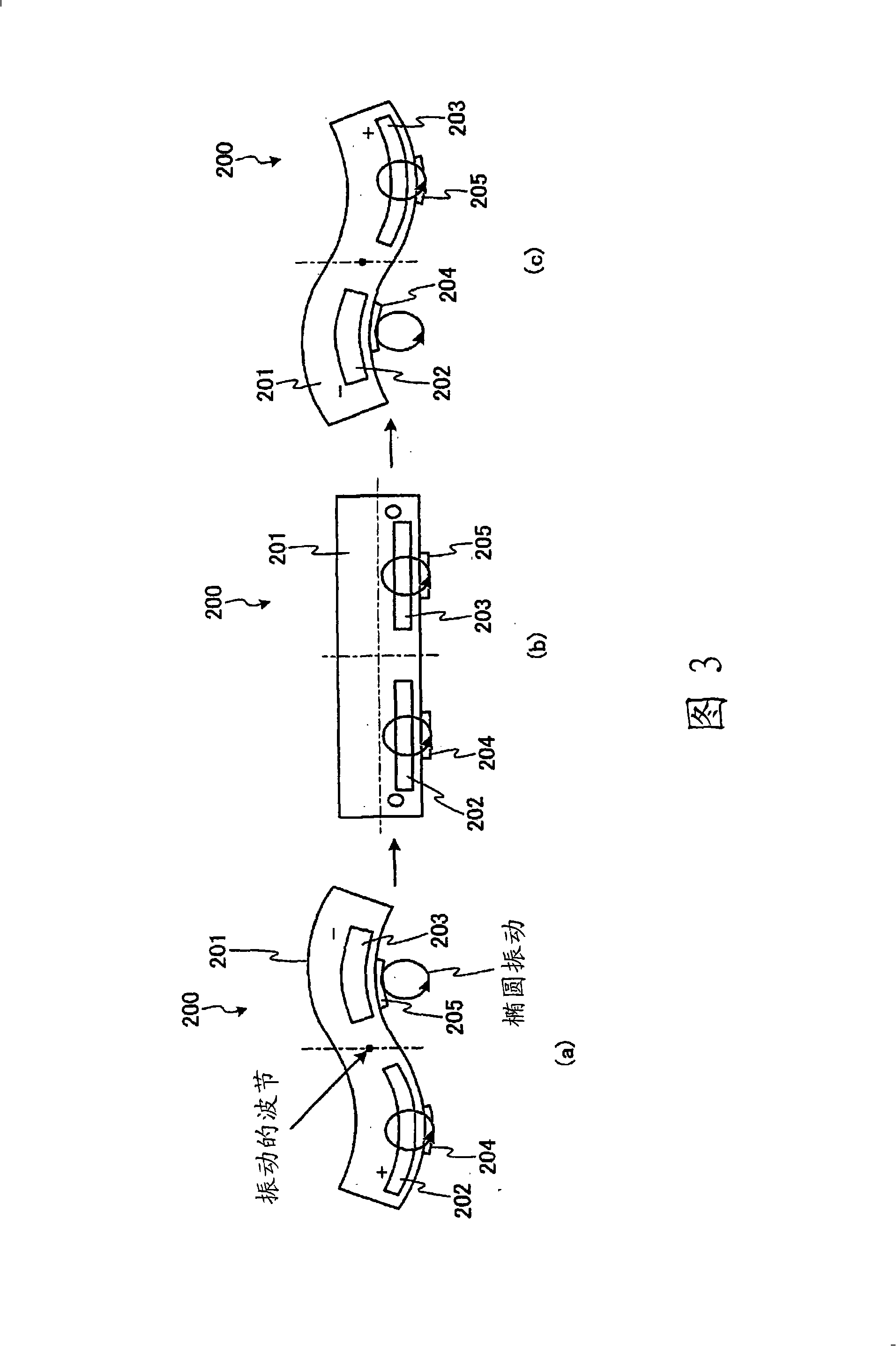

Method used

Image

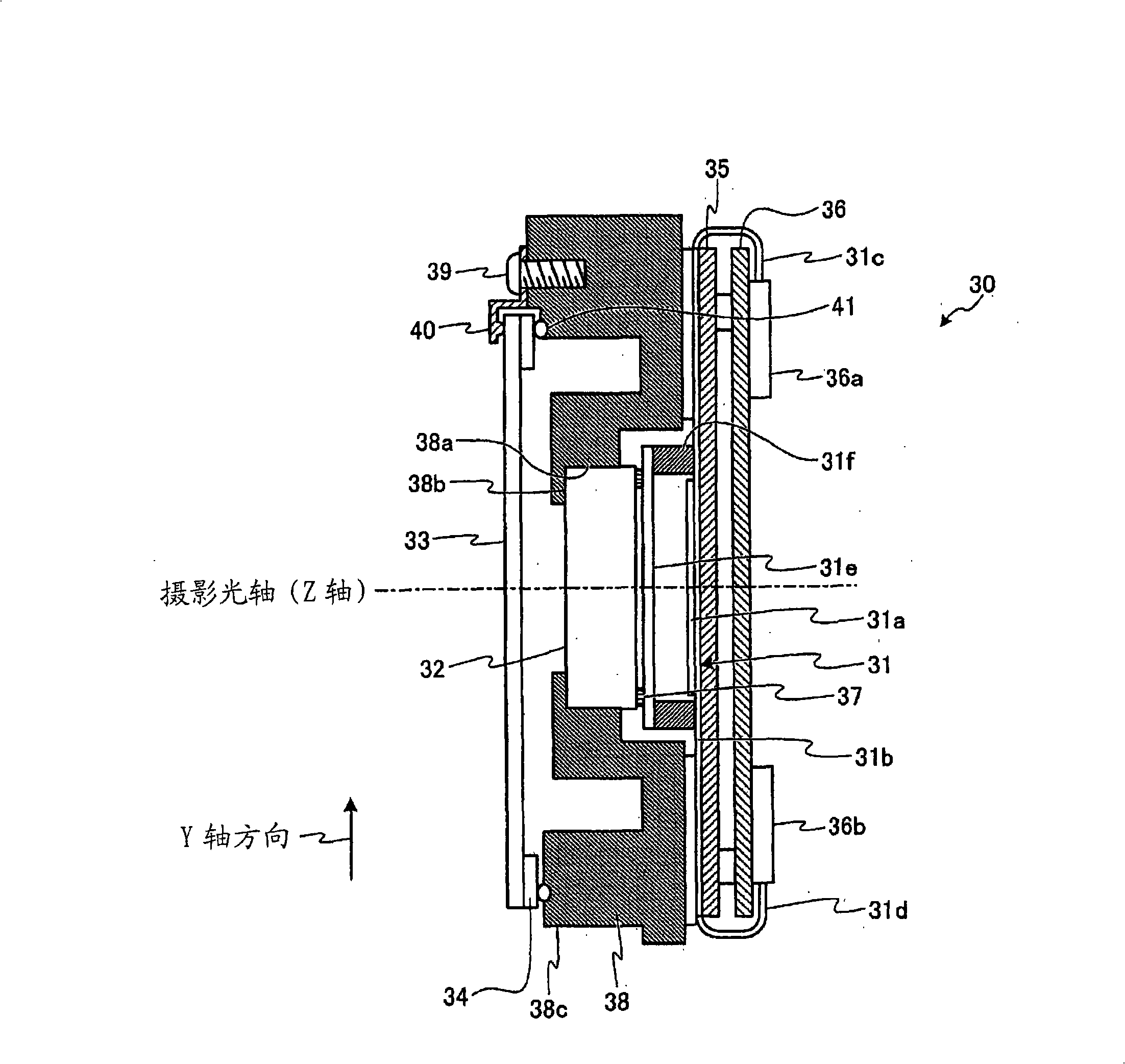

Examples

Deformed example 1

[0080] Figure 15 It is a schematic bottom view showing the enlarged X-axis drive mechanism part of Modification 1, Figure 16 is along Figure 15 Sectional view of line E-E in . In Modification 1, an annular thin piece 353x made of silicone rubber is also interposed between the pressing plate 341x and the frame 302 as a vibration damping member at the mounting portion where the pressing plate 341x is attached with the screw 345x. As a result, the pressing plate 341x is sandwiched between the sheets 349x and 353x at one end and held in a pressure-bonded state. Here, assuming that the thin piece 353x is made of a hard member, the pressing plate 341x cannot move in the pressing direction, which hinders the pressing action. However, since the thin piece 353x is made of a soft member such as silicone rubber, it is effective by the action of the pressing spring 342x. In the case of force, the pressing part 343x is not hindered by the pressing of the pressing plate 341x due to th...

Deformed example 2

[0084] Figure 17 It is a schematic bottom view in which the X-axis drive mechanism part of Modification 2 is extracted and enlarged. In Modification 2, both ends of the pressing plate 341x are curved, and a pressing spring (pressing member) 356x is also arranged on the other end, so that the supporting and pressing structures at both ends are the same. That is, between the pressing plate 341x and the screw 357x, a cylindrical bush 358x having a size to fit the reference hole 344x and annular thin pieces 359x, 360x arranged at both ends of the pressing spring 356x are interposed. Compared with the rigid pressing plate 341x, the bushing 358x, the sheets 359x, 360x are made of soft materials, for example, the bushing 358x is made of synthetic resin, and the sheets 359x, 360x are made of silicone rubber, and they function as vibration damping members. Function. By interposing these bushings 358x and sheets 359x, 360x, one end side of the pressing plate 341x is positioned with r...

Deformed example 3

[0086] 18 is a schematic bottom view showing an enlarged X-axis drive mechanism section of Modification 3. FIG. In Modification 3, instead of the screws 345x and 347x, stepped screws 361x and 362x that can be positioned in the screwing direction are used, and rubber bushes made of, for example, silicon rubber are interposed around the stepped screws 361x and 362x. Sets 363x, 364x come as vibration damping components. Also in the case of Modification 3, the same operation and effect as in the case of the present embodiment can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com