Beating machine

A technology of driving machine and contact arm, which is applied in the direction of portable motorized devices, nailing tools, manufacturing tools, etc., and can solve problems such as operational damage of driving machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

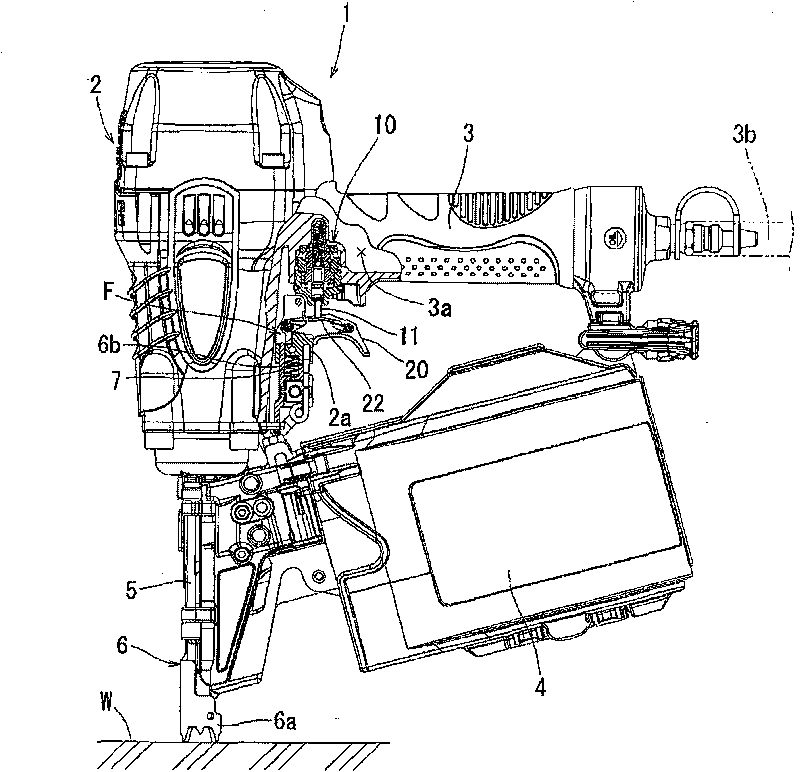

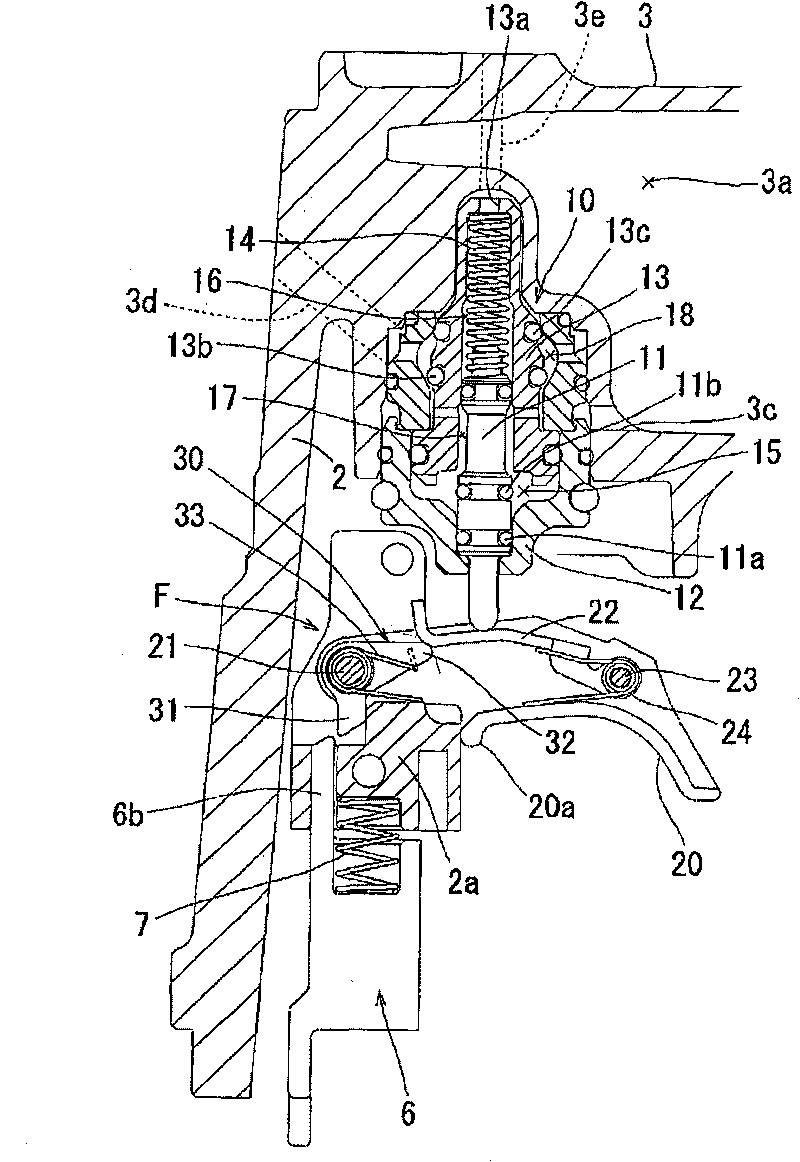

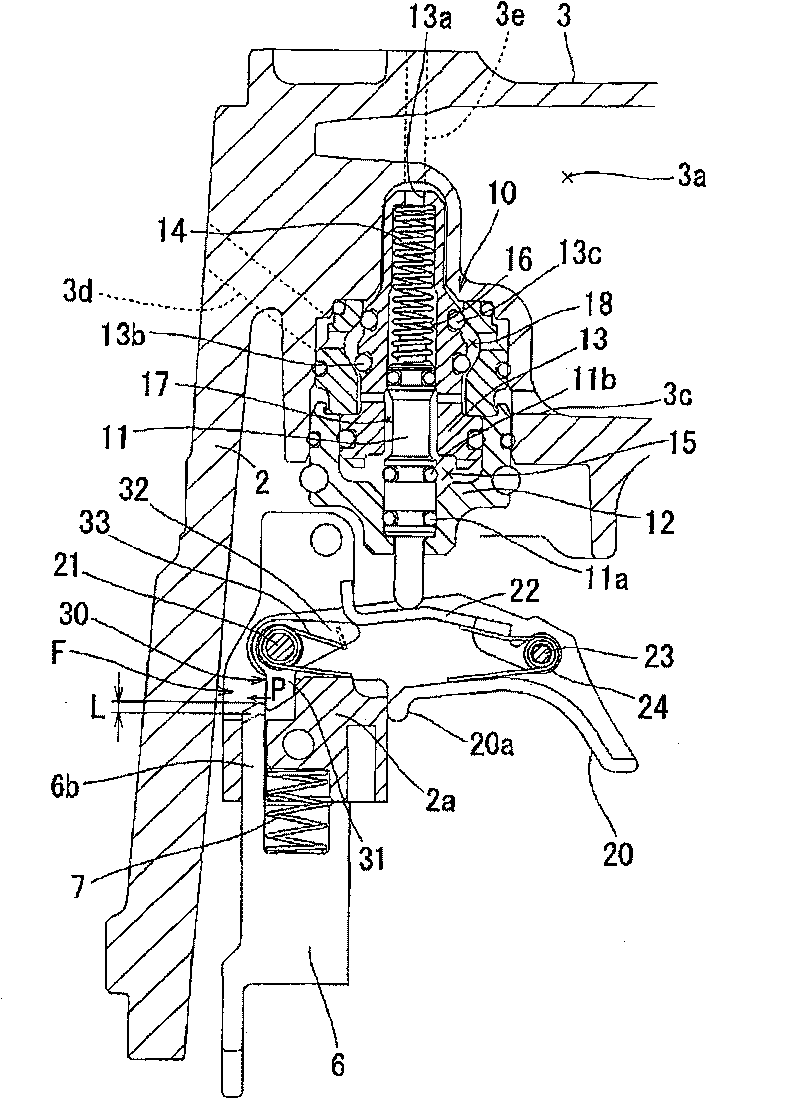

[0028] Below, based on Figure 1 to Figure 7 Embodiments of the present invention will be described. figure 1 The driver 1 according to this embodiment is shown. In this embodiment, as the driver 1 , a compressed air nail driver that operates using compressed air as a driving source is exemplified. The same can also be provided for screwdrivers. In addition, in this specification, the direction in which the driver is driven is set as the lower side, and it is used for description of each structure and member.

[0029] This driver 1 includes a main body 2 , a handle 3 and a staple magazine 4 . A piston and an air cylinder for driving a driver (nail) into a driving material are incorporated in the main body 2 . A firing pin for driving the driving part is installed on the piston. The striker moves within a striker guide rail 5 protruding from the lower surface of the main body 2 . Drivers are supplied one by one into the striker guide rail 5 .

[0030] Intake and exhaust of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com