Method for extracting silibinin

A technology for silibinin and silymarin, which is applied in the field of extraction of medicines for treating liver diseases, can solve the problems of poor operability, low yield, poor product quality and the like, and achieves the effects of improving the total yield and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

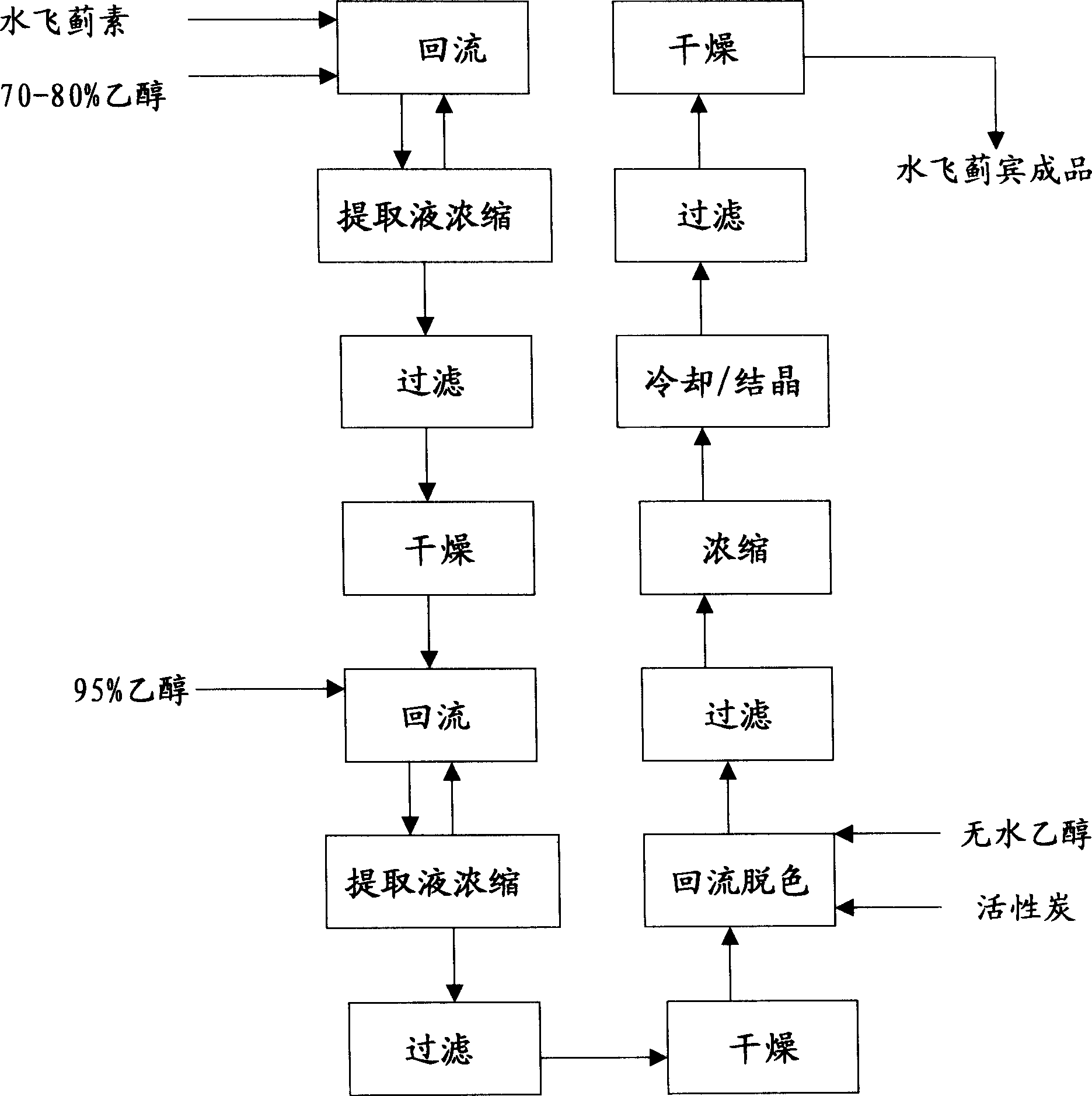

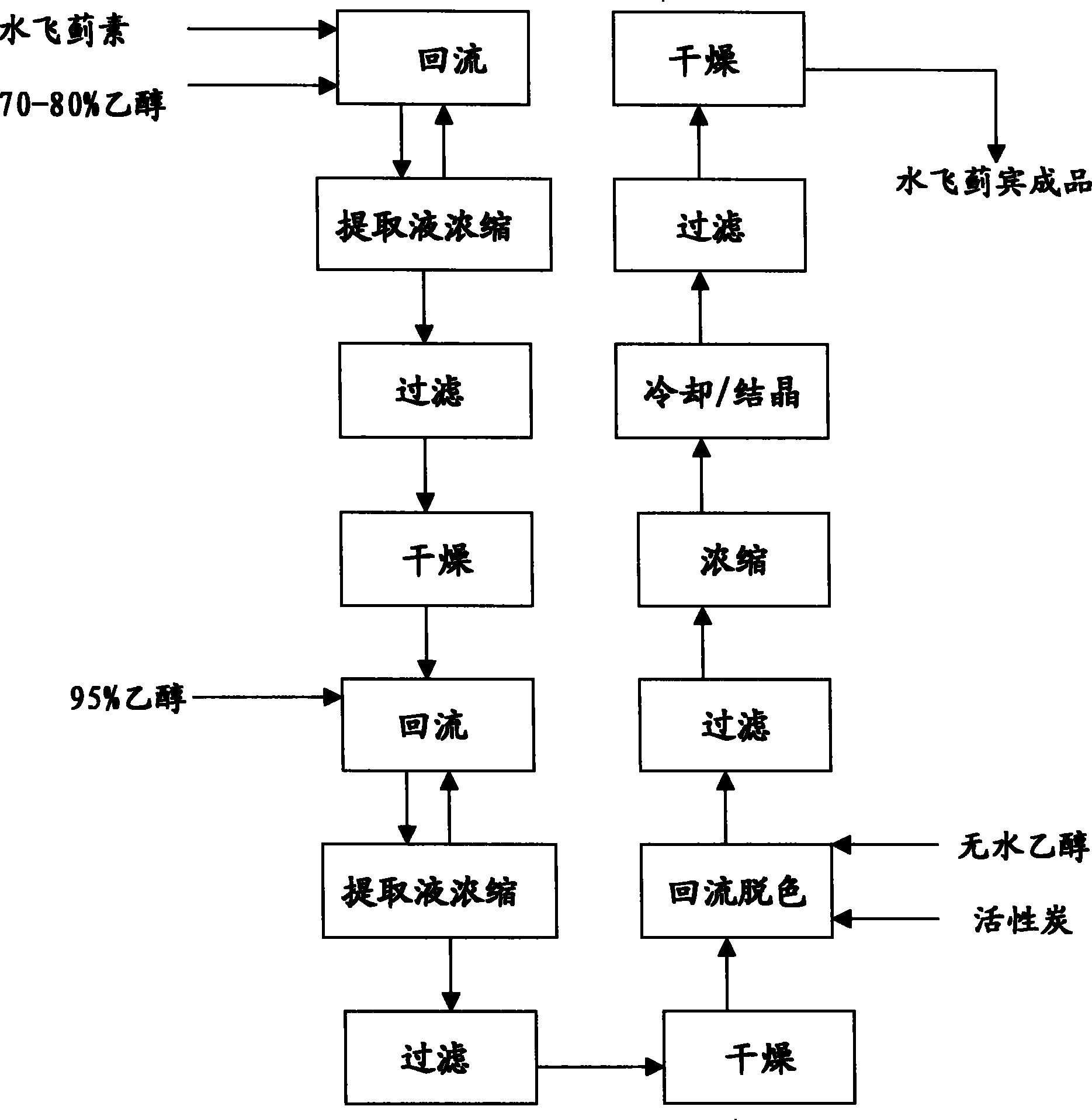

Method used

Image

Examples

Embodiment 1

[0049] Add 300kg of 80% ethanol into the extraction pot, and add 50kg of silymarin under stirring. Heated and refluxed for 30 minutes. Open the bottom valve of the extraction pot, let the extract part enter the concentration pot, heat and concentrate, concentrate the ethanol and then enter the extraction pot, and concentrate and extract for 1.5 hours. Stop the extraction, filter the extraction pot extract, wash with 80% ethanol, and filter dry to obtain a yellow muddy precipitate, which is vacuum-dried at 80° C. for 6 hours to obtain crude silibinin, weighing 12.8 kg, and the yield is 25.6%.

[0050] Add 75kg of 95% ethanol and 12.5kg of crude silibinin in the extraction pot. Heated and refluxed for 30 minutes. Open the bottom valve of the extraction pot to allow the extract part to enter the concentration pot, and after concentration, the ethanol enters the extraction pot. Concentrate extraction cycle for 1 hour. Stop the extraction, filter the extraction pot extract, was...

Embodiment 2

[0053] Add 800kg of 70% ethanol into the extraction pot, and add 100kg of silymarin under stirring. Reflux for 30 minutes. Open the bottom valve of the extraction pot, let the extract part enter the concentration pot, heat and concentrate, concentrate the ethanol and then enter the extraction pot. Concentrated extraction cycle for 4 hours. Stop the extraction, filter the extraction pot extract, wash with 70% ethanol, and filter dry to obtain a yellow muddy precipitate, which is vacuum-dried at 80° C. for 10 hours to obtain crude silibinin weighing 26 kg with a yield of 26.0%.

[0054] Add 204kg of 95% ethanol and 25.5kg of crude silibinin into the extraction pot, stir and heat to reflux for 30 minutes. Open the bottom valve of the extraction pot to allow the extract part to enter the concentration pot, and after concentration, the ethanol enters the extraction pot. Concentrated extraction cycle for 4 hours. Stop the extraction, filter the extraction pot extract, wash with ...

Embodiment 3

[0057] Add 700kg of 75% ethanol into the extraction pot, and add 100kg of silymarin under stirring. Reflux for 30 minutes. Open the bottom valve of the extraction pot, let the extract part enter the concentration pot, heat and concentrate, concentrate the ethanol and then enter the extraction pot. Concentrated extraction cycle for 3 hours. Stop the extraction, filter the extraction pot extract, wash with 75% ethanol, filter and dry to obtain a yellow muddy precipitate, and vacuum-dry at 80° C. for 8 hours to obtain crude silibinin, weighing 26.4 kg; the yield is 26.4%.

[0058] Add 170kg of 95% ethanol and 25kg of crude silibinin into the extraction pot, stir and heat to reflux for 30 minutes. Open the bottom valve of the extraction pot to allow the extract part to enter the concentration pot, and after concentration, the ethanol enters the extraction pot. Concentrated extraction cycle for 2 hours. Stop the extraction, filter the extraction pot extract, wash with 95% ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com