Composite pyroelectricity material, preparation method thereof, and method for preparing silicon-base thick film

A composite material and pyroelectric technology, applied in thermoelectric devices, circuits, electrical components, etc., can solve the problems of low voltage response figure of merit, decrease of detection rate figure of merit, small dielectric constant, etc., and achieve high voltage response figure of merit , small dielectric constant and low film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

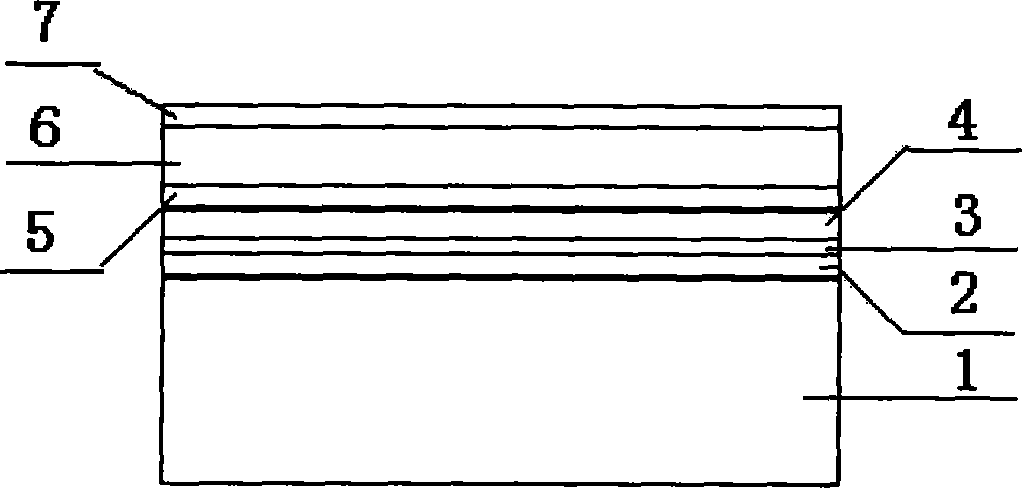

preparation example Construction

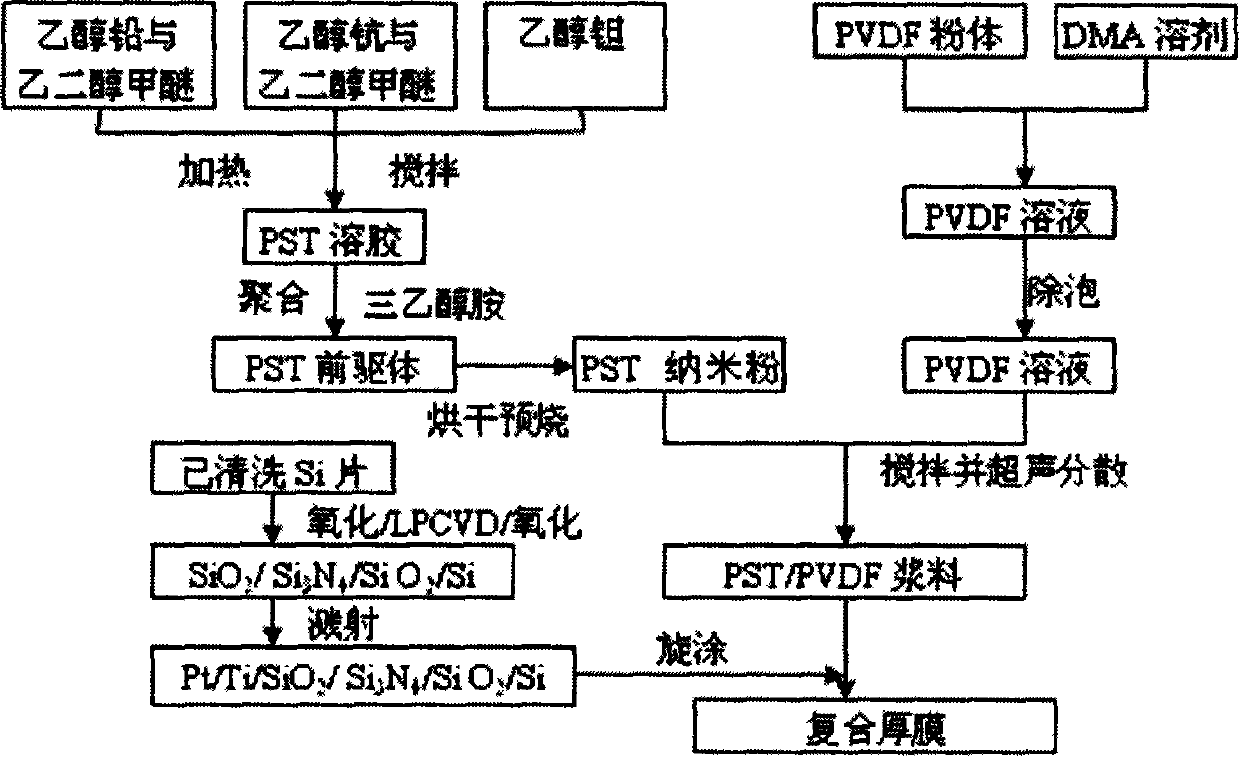

[0029] The preparation method of the above-mentioned composite pyroelectric material comprises the following steps:

[0030] (1) Preparation of lead scandium tantalate (PST) precursor sol. According to the chemical formula Pb 1+x (Sc 0.5 Ta 0.5 )O 3 To control the stoichiometric ratio (Ta+Sc) / Pb=1 / (1+x), 0.05≤x≤0.1, first dissolve scandium acetate in the solvent ethylene glycol methyl ether or ethylene glycol ether, according to 1:10~ Add catalyst concentrated nitric acid at a volume ratio of 1:20, stir until the solution becomes clear, then add tantalum ethoxide (Ta(OC 2 h 5 ) 5 ), stirred until clear to form ScTaO 4 (PST) precursor solution, then lead acetate is dissolved in the solvent ethylene glycol methyl ether or ethylene glycol ether, stirred to a clear solution, then the two solutions are mixed, stirred to form scandium lead tantalate precursor sol;

[0031] (2) Preparation of scandium lead tantalate nanopowder. Scandium lead tantalate precursor sol is stored...

Embodiment 1

[0044] (1) Scandium acetate (Sc(CH 3 COO) 3 ·yH 2 O) in the oven at a constant temperature of 120°C for 3 hours to remove the water of crystallization, get 11.1 grams and dissolve it in 65 milliliters of ethylene glycol methyl ether, and add 1 milliliter of concentrated nitric acid, stir until a clear solution, then add 20.3 grams of tantalum ethylate ( Ta(OC 2 h 5 ) 5 ), stirred for 2 hours to clarification, added 4 milliliters of triethanolamine as a stabilizing agent, then dissolved the lead acetate of 17.06 gram decrystallized water in 35 milliliters of ethylene glycol methyl ether, stirred to a clear solution, then mixed the two solutions, stirred for 3 hours to form scandium lead tantalate precursor sol;

[0045] (2) Bake the lead scandium tantalate precursor sol aged for 2 days at 120°C for 4 hours to obtain a dry gel, then grind the dry gel into powder, pass through a 200-mesh sieve, and then heat up at 200°C / h Raise the rate to 650°C and pre-fire for 3 hours, ba...

Embodiment 2

[0056] (1) Dissolve 11.1 grams of scandium acetate in 65 milliliters of ethylene glycol ether, add 1 milliliter of concentrated nitric acid, stir until the solution is clear, then add 20.3 grams of tantalum ethanol (Ta(OC 2 h 5 ) 5 ), stirred for 2 hours until clear, added 4 milliliters of triethanolamine as a stabilizer, then dissolved 17.06 grams of lead acetate in 35 milliliters of ethylene glycol ether, stirred to a clear solution, then mixed the two solutions, heated and stirred for 4 hours to form scandium tantalum Lead acid precursor sol;

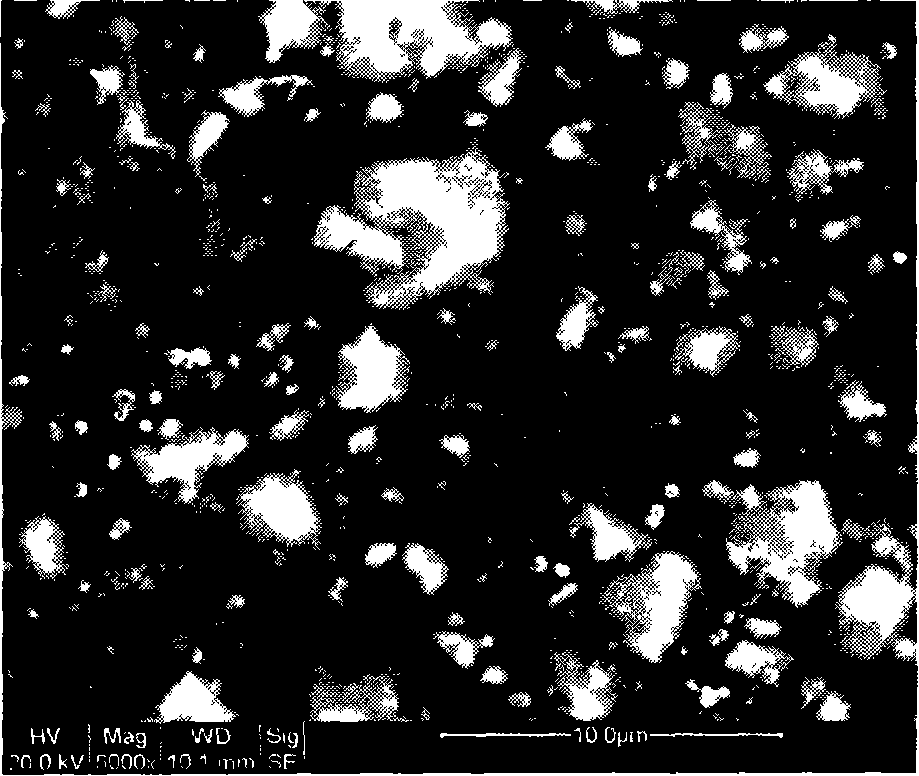

[0057] (2) Dry the lead scandium tantalate precursor sol aged for 4 hours, pre-fire it at 800°C for 3 hours, ball mill and dry to obtain lead scandium tantalate nanopowder with a particle size of about 100nm;

[0058] (3) Dissolving 5 grams of PVDF powder in 95 grams of N,N-dimethylacetamide solution at 60°C;

[0059] (4) Pour the PVDF solution into the ceramic powder according to the PST volume fraction of 30%, and after stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com