Negative-pressure superconductor automatic opening-closing vented explosion device

An automatic opening and closing, superconducting technology, applied in the direction of valve devices, engine components, safety valves, etc., can solve the problems of secondary explosion, complex structure, troublesome adjustment of negative pressure of initiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

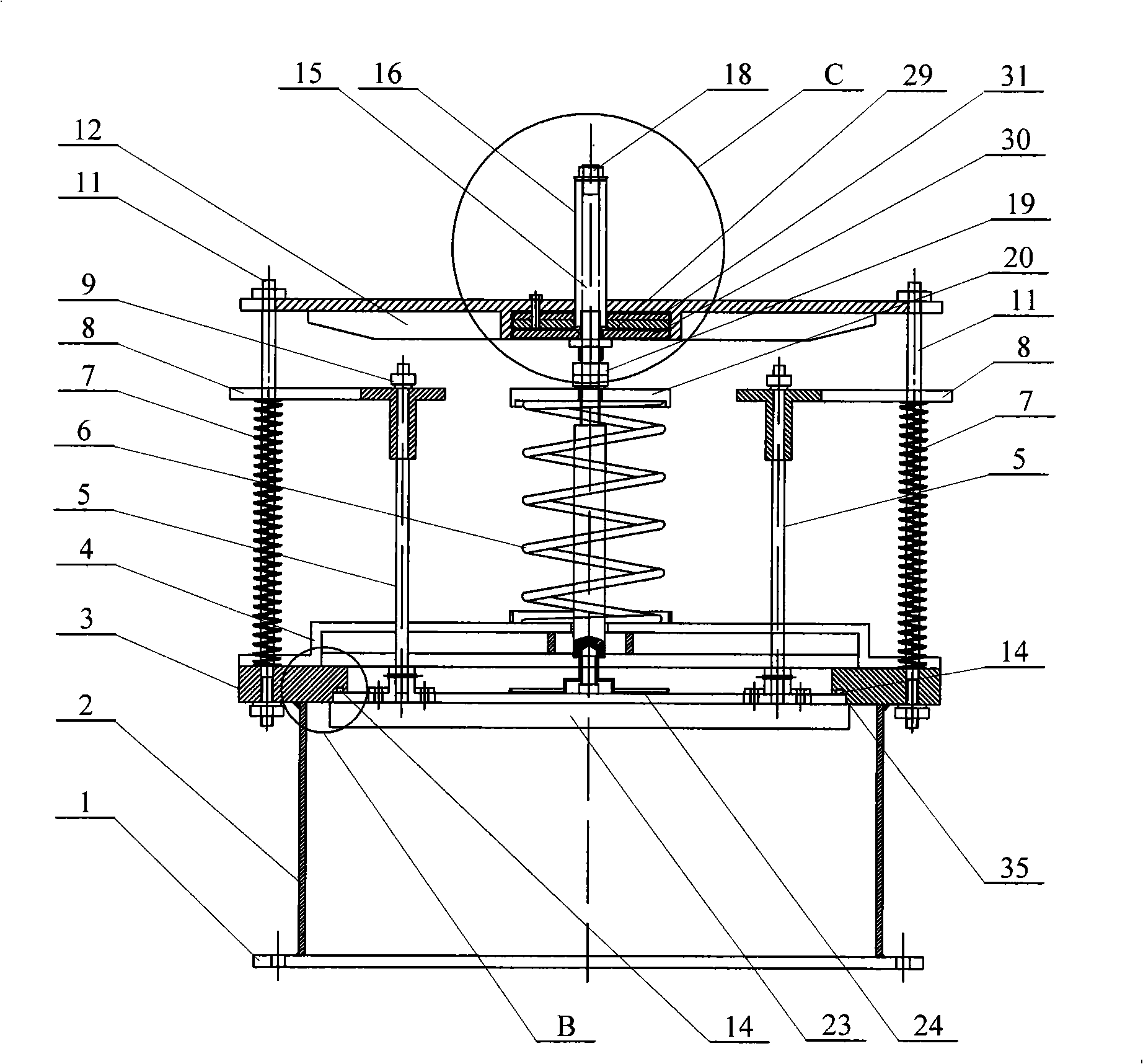

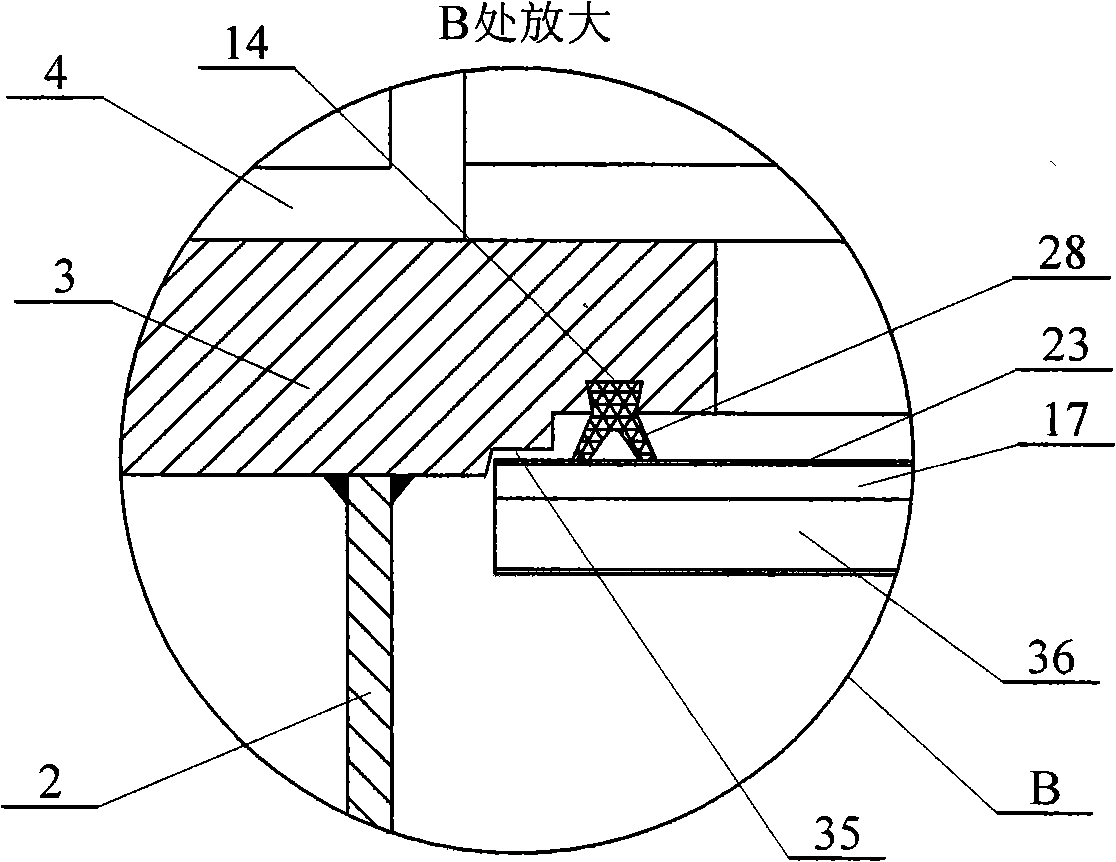

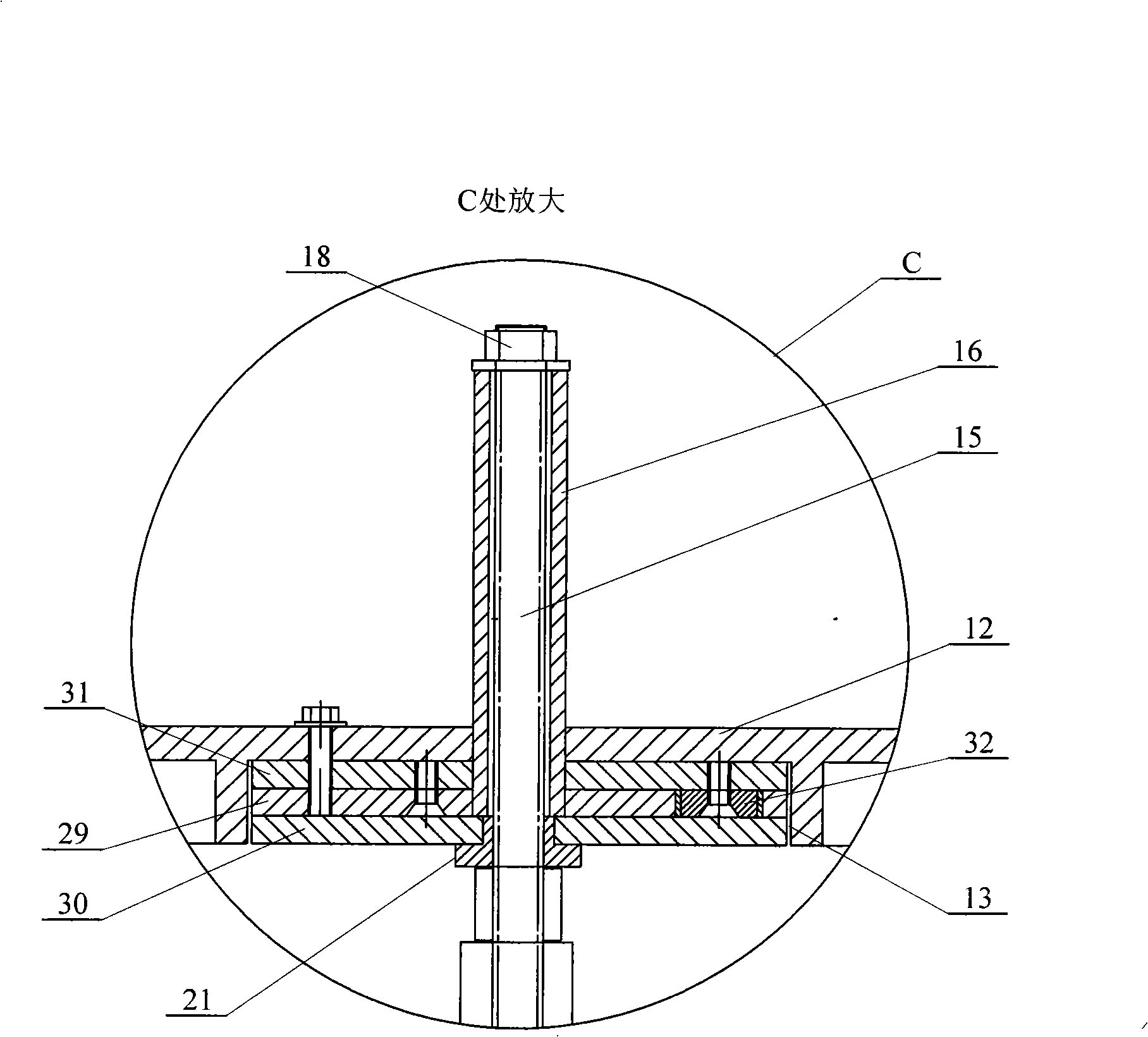

[0005] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) This embodiment includes a lower flange 1, a cylinder body 2, an upper flange 3, a lower bracket 4, three to five poles 5, a return spring 6, a guide post spring 7, a spring baffle 8, and a spring stop Plate adjustment bolt 9, three to five guide columns 11, upper bracket 12, center pillar 15, spacer 16, center pillar bolt 18, return spring adjustment nut 19, return spring baffle 20, door body (bonnet) 23 and central pillar connector 24, the lower flange 1 is fixedly connected to the lower end of the cylinder 2, the upper flange 3 is fixedly connected to the upper end of the cylinder 2, and the lower bracket 4 is fixed on the upper side of the upper flange 3, The door body 23 is arranged on the lower side of the upper flange 3 in the cylinder body 2, and the lower side of the upper flange 3 is provided with a groove 35, and the door body 23 is matched with the groove 35 on the upper flange 3, The central pil...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , figure 2 ) The difference between this embodiment and the specific embodiment one is that it adds a sealing rubber ring 28, and an annular groove 14 is arranged on the upper flange 3 of the matching position with the door body 23, and the sealing rubber ring 28 is located on the inside the ring groove 14. The sealing rubber ring 28 is used to increase the degree of sealing between the door body 23 and the upper flange 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see figure 1 , figure 2 ) The difference between this embodiment and the second embodiment is that the door body 23 is composed of an aluminum alloy frame 36 and a stainless steel plate 17 , and the stainless steel plate 17 is fixed on the upper side of the aluminum alloy frame 36 . The composite sealed door body (bonnet) made of stainless steel plate and aluminum alloy frame has the advantages of light weight and strong rigidity, and can realize high-efficiency explosion relief. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com