Method for aligning circumference equipartion same type small-sized equipment group

A small device, the same type of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

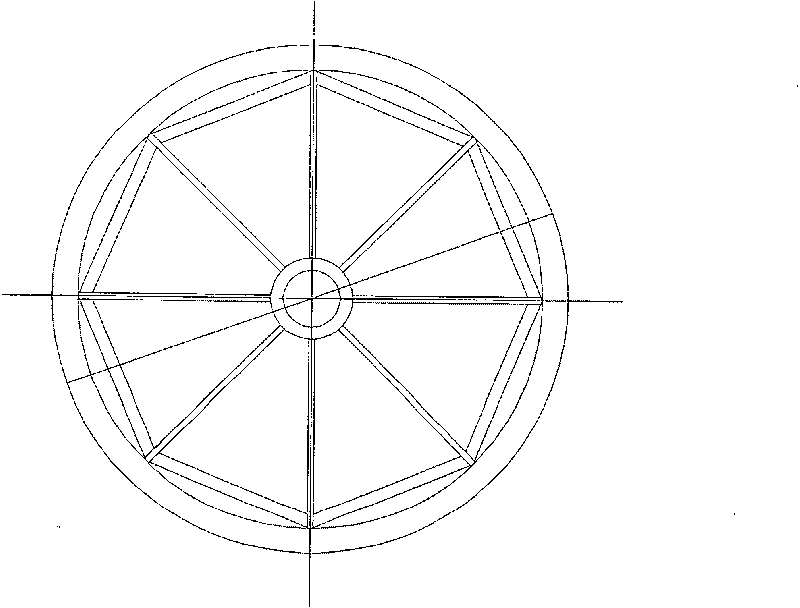

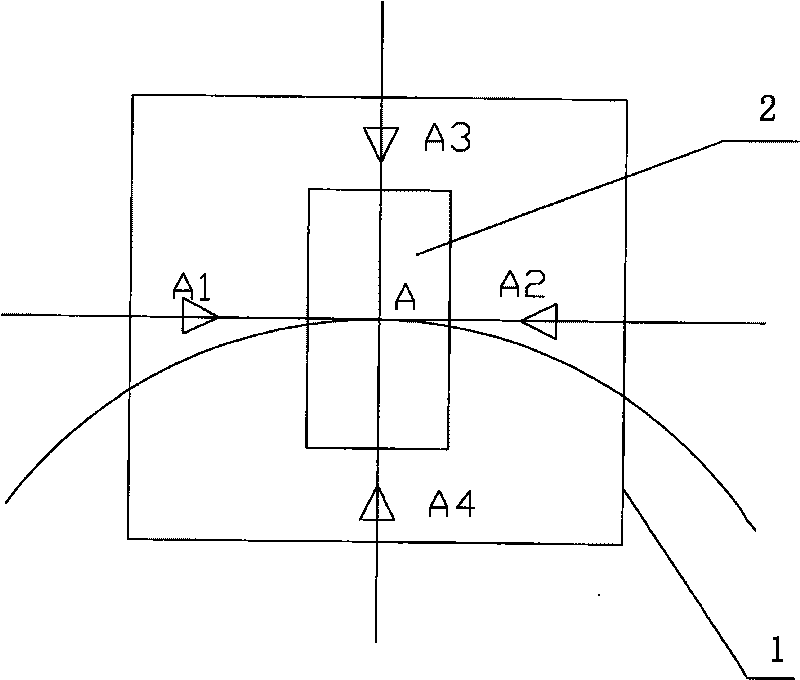

[0031] Such as Figure 10 As shown, the method of simultaneously finding the small equipment groups of the same type evenly distributed on the circumference through the three-point positioning of the template includes the following steps:

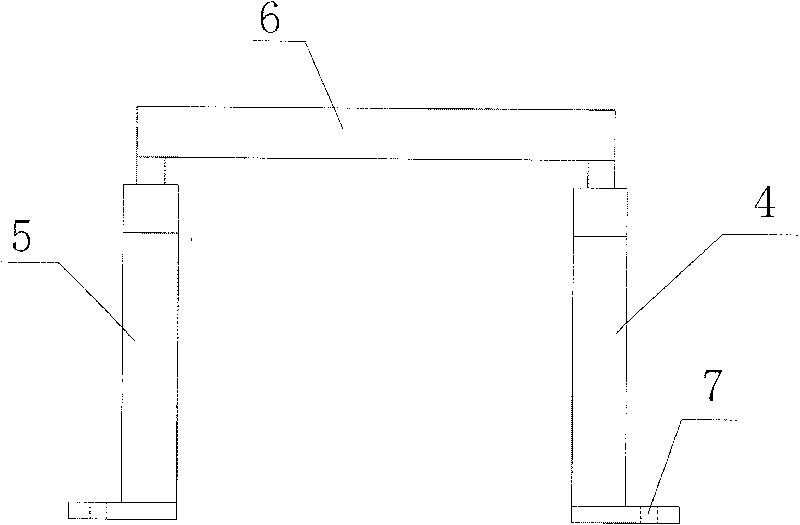

[0032] 1) Preparation of sample frame: such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, the sample frame is composed of the first door frame 4, the second door frame 5, the channel steel sample plate 6, and the connecting bolts. The bottoms of the first door frame 4 and the second door frame 5 are respectively provided with silicon steel high temperature The anchor bolt connection hole 7 corresponding to the anchor bolt position of the supporting roller (small equipment that needs to be aligned) of the annealing annular heating furnace (that is, the first door-shaped bracket 4 and the second door-shaped bracket 5 can be respectively controlled by the supporting roller's Anchor bolts), the tops of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com