Light choppers

A technology of optical chopper and rotating shaft, which is applied in the direction of optics, instruments, optical components, etc., and can solve the convenience and disadvantages of simplifying equipment measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

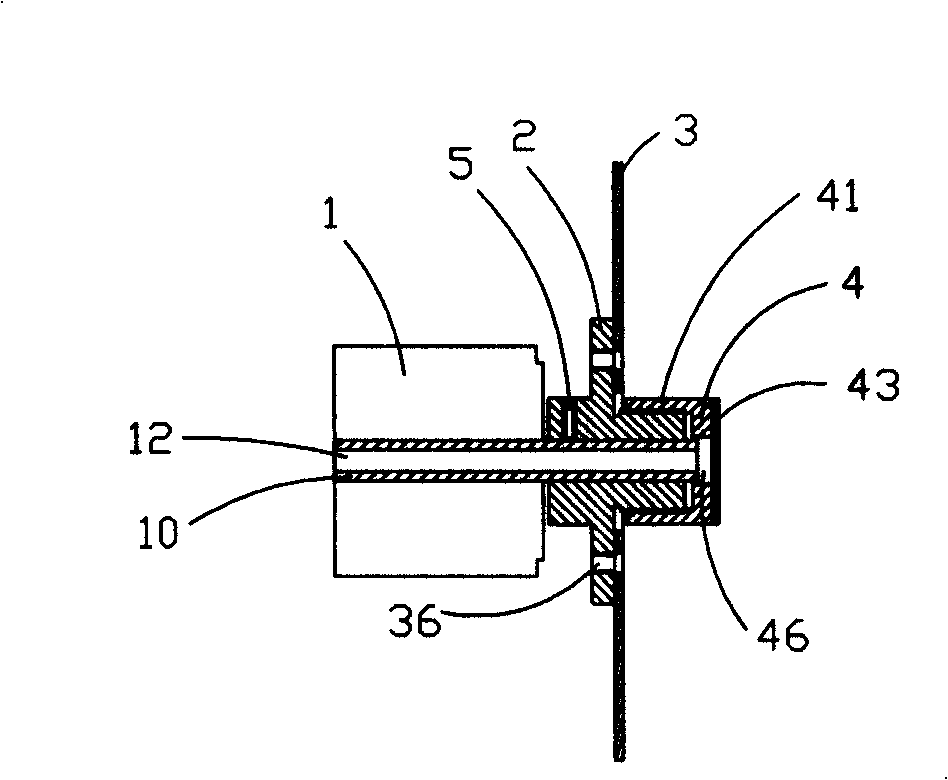

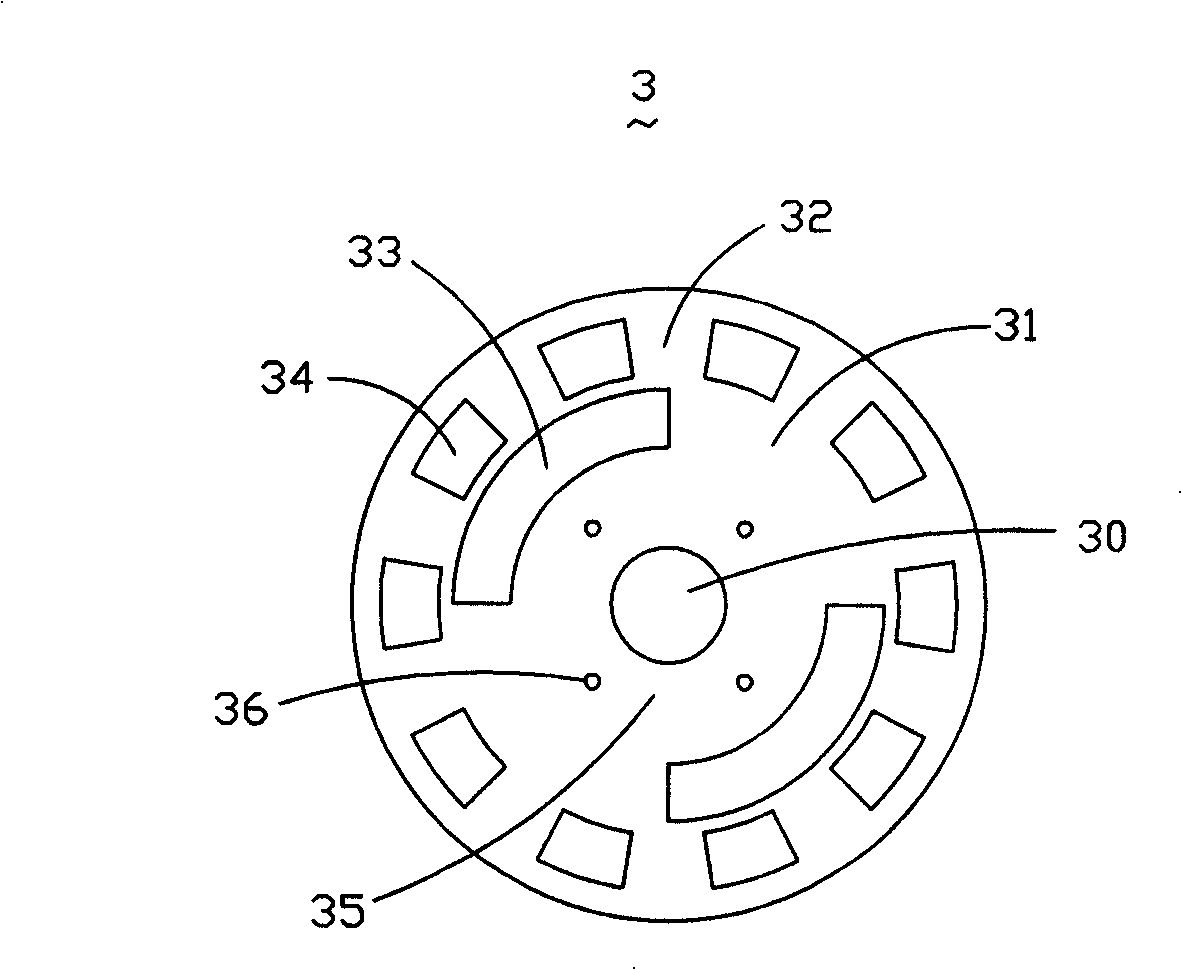

[0023] refer to figure 1 , The optical chopper of the present invention includes: a stepping motor 1, a flange 2 fixedly sleeved on the motor shaft 10, a modulation disc 3 fixedly installed on the flange 2, and a polarizer 4 installed on the flange 2. The rotating shaft 10 is provided with an axial through hole 12, that is, it is a hollow shaft.

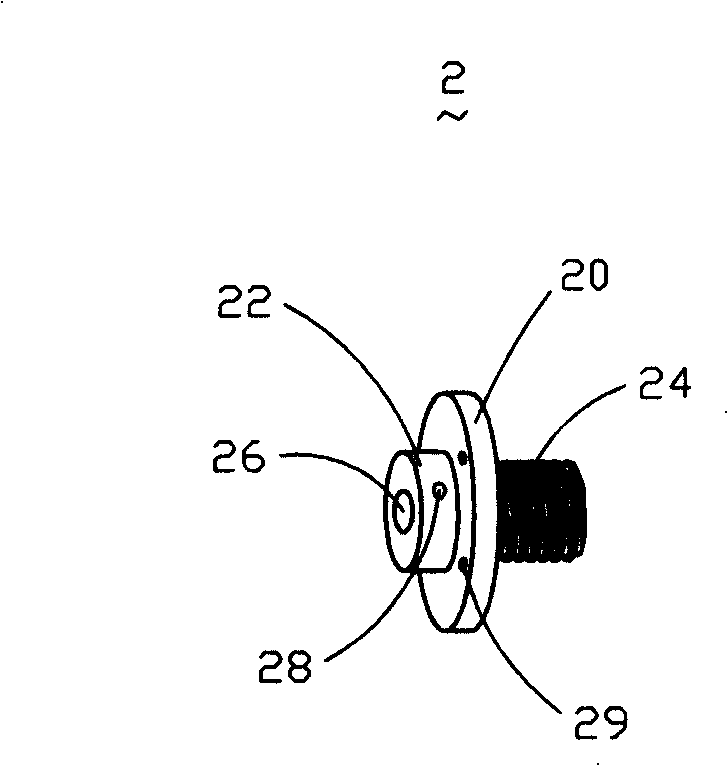

[0024] Please also see figure 2 The flange 2 includes a flange plate 20, a fixed portion 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com