Electronic part encapsulation module, external cover and its making method

A technology for electronic components and packaging modules, which is applied in the field of outer covers of electronic component packaging modules, and can solve problems such as unavoidable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

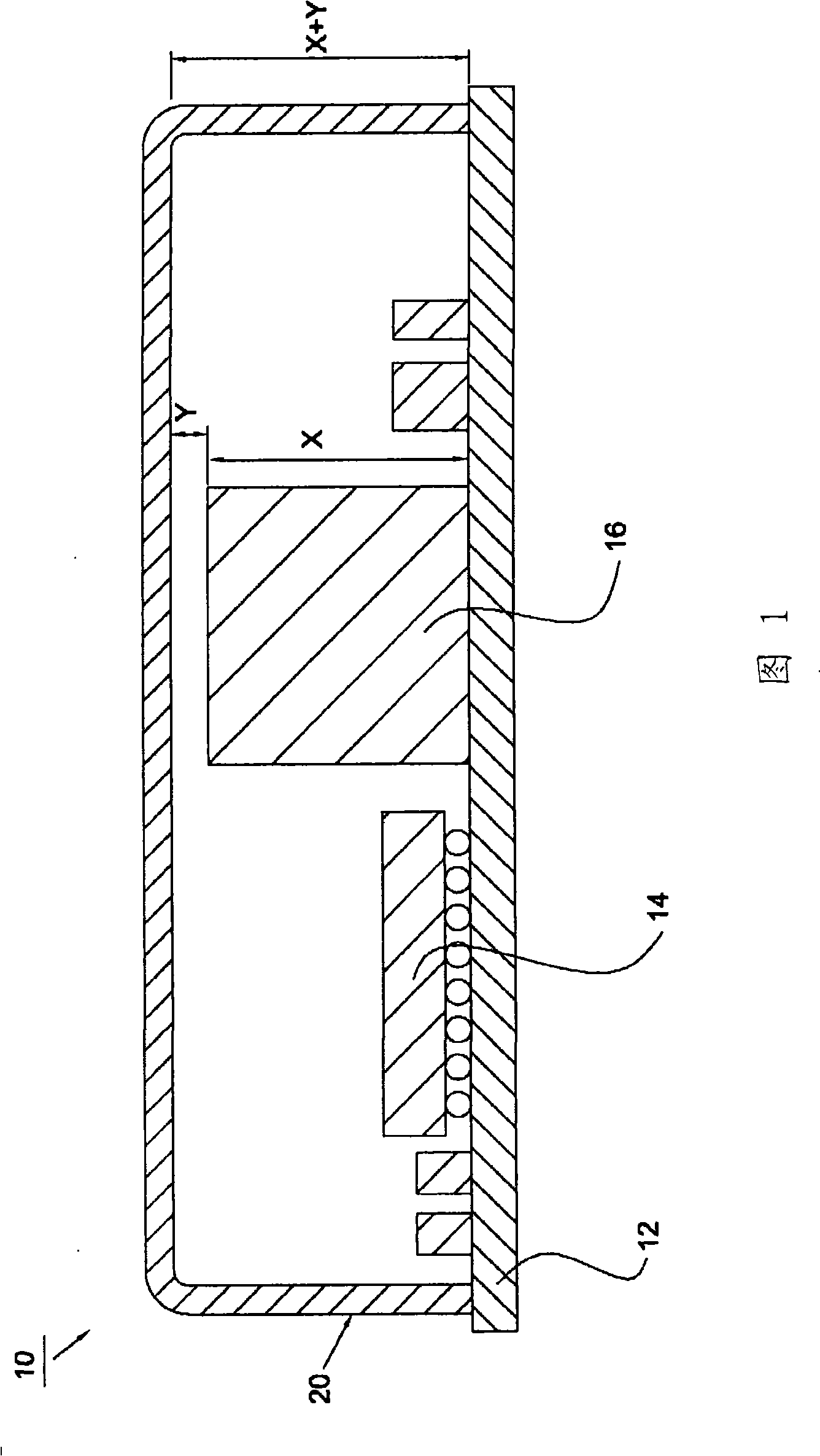

[0037] refer to image 3 , which shows an outer cover 220 according to an embodiment of the present invention. The outer cover 220 includes an inner layer 222 and an outer layer 224 . The outer layer 224 is disposed on the surface 223 of the inner layer 222 to form an outer cover 220 . The outer cover 220 has a top 226 and an annular supporting portion 228 , and the annular supporting portion 228 is connected to the top 226 .

[0038] The inner layer 222 and the outer layer 224 are respectively made of a non-conductive material and a conductive material. The conductive material may be a metal, such as copper or iron metal. The non-conductive material is non-metal, such as plastic or rubber.

[0039] The manufacturing method of the outer cover 220' of an embodiment of the present invention comprises the following steps: first, refer to Figure 4 , providing an inner layer 222 as a base layer. refer to Figure 5 , an outer layer 224 is formed on the surface 223 of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com