An oxide-based thin film transistor type ultraviolet detector and a preparation method thereof

A technology of thin-film transistors and ultraviolet detectors, applied in the field of ultraviolet detectors, can solve the problems of increasing manufacturing complexity and reducing performance, and achieve the effects of improving photoelectric conversion ability, increasing electrical conductivity, and improving response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

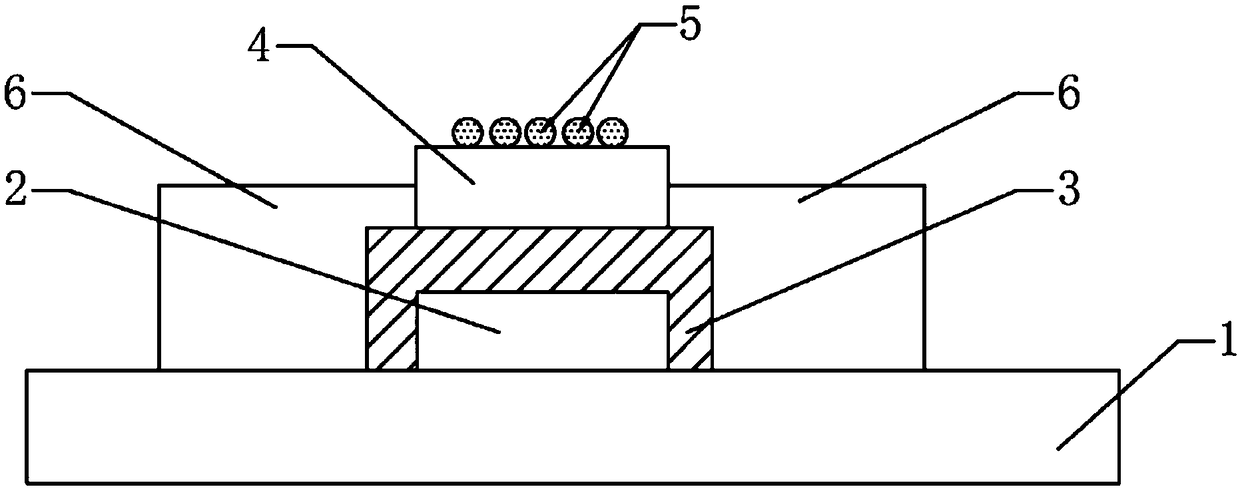

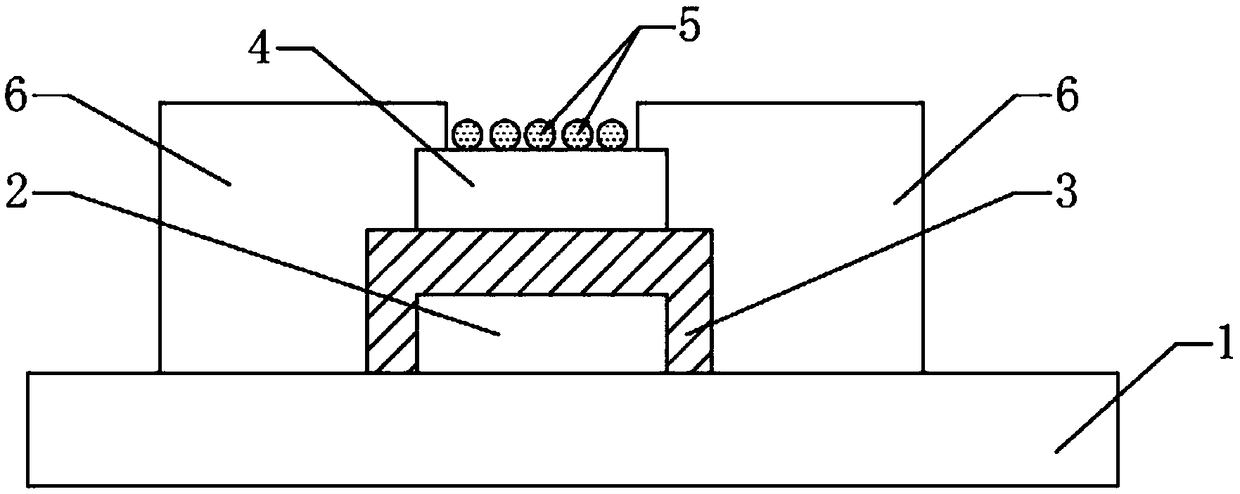

[0047] See figure 1 , an oxide-based thin film transistor type ultraviolet detector, comprising a substrate 1, a composite layer arranged on the upper surface of the substrate, and metal electrodes 6 symmetrically clamped on both sides of the composite layer; the composite layer Including electrode layer 2, SiO 2 / Si 3 N 4 Composite insulating layer 3, IGZO channel layer 4 and nano metal particles 5, the lower surface of the electrode layer 2 is connected to the upper surface of the substrate 1, the SiO 2 / Si 3 N 4 The composite insulating layer 3 is coated on the surface of the electrode layer 2 in an inverted buckle shape, and the IGZO channel layer 4 is arranged on the SiO 2 / Si 3 N 4 The upper surface of the composite insulating layer 3, the nano-metal particles 5 are distributed on the upper surface of the IGZO channel layer 4; the SiO 2 / Si 3 N 4 Both sides of the composite insulating layer 3 and both sides of the IGZO channel layer 4 are connected to the metal...

Embodiment 2

[0062] The difference between this embodiment and above-mentioned embodiment 1 is:

[0063] The stabilizer is polyethylene glycol, and the solvent is ethylene glycol methyl ether.

[0064] In the step A, the ultrasonic treatment frequency is 100 kHz, and the ultrasonic treatment time is 8 min; the stirring speed is 800 rpm, and the stirring time is 18 h.

[0065] Step A1 is also included after step A: filter the IGZO precursor prepared in step A through a filter head with a pore size of 0.15-0.21 μm, and then age for 18 hours to obtain a stable IGZO precursor.

[0066] In the step C, the rotational speed of the spin coating is 4800 rpm, the spin coating time is 28 s, the annealing temperature is 300° C., and the annealing time is 7 min.

Embodiment 3

[0068] The difference between this embodiment and above-mentioned embodiment 1 is:

[0069] The stabilizer is ethanolamine, and the solvent is ethylene glycol methyl ether.

[0070] In the step A, the ultrasonic treatment frequency is 150 kHz, and the ultrasonic treatment time is 12 minutes; the stirring speed is 1000 rpm, and the stirring time is 12 hours.

[0071] Step A1 is also included after the step A: filter the IGZO precursor prepared in step A through a filter head with a pore size of 0.15-0.21 μm, and then age for 24 hours to obtain a stable IGZO precursor.

[0072] In the step C, the rotational speed of the spin coating is 5000 rpm, the spin coating time is 25 s, the annealing temperature is 400° C., and the annealing time is 6 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com