Integrated forming production method for firecrackers

A production method and technology for firecrackers, which are applied in the field of integrated production of firecrackers, can solve the problems of no shock absorption and buffering effect, large firecrackers filling, increased safety hazards, etc., and achieve compact structure, environmental protection, and extended storage. period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

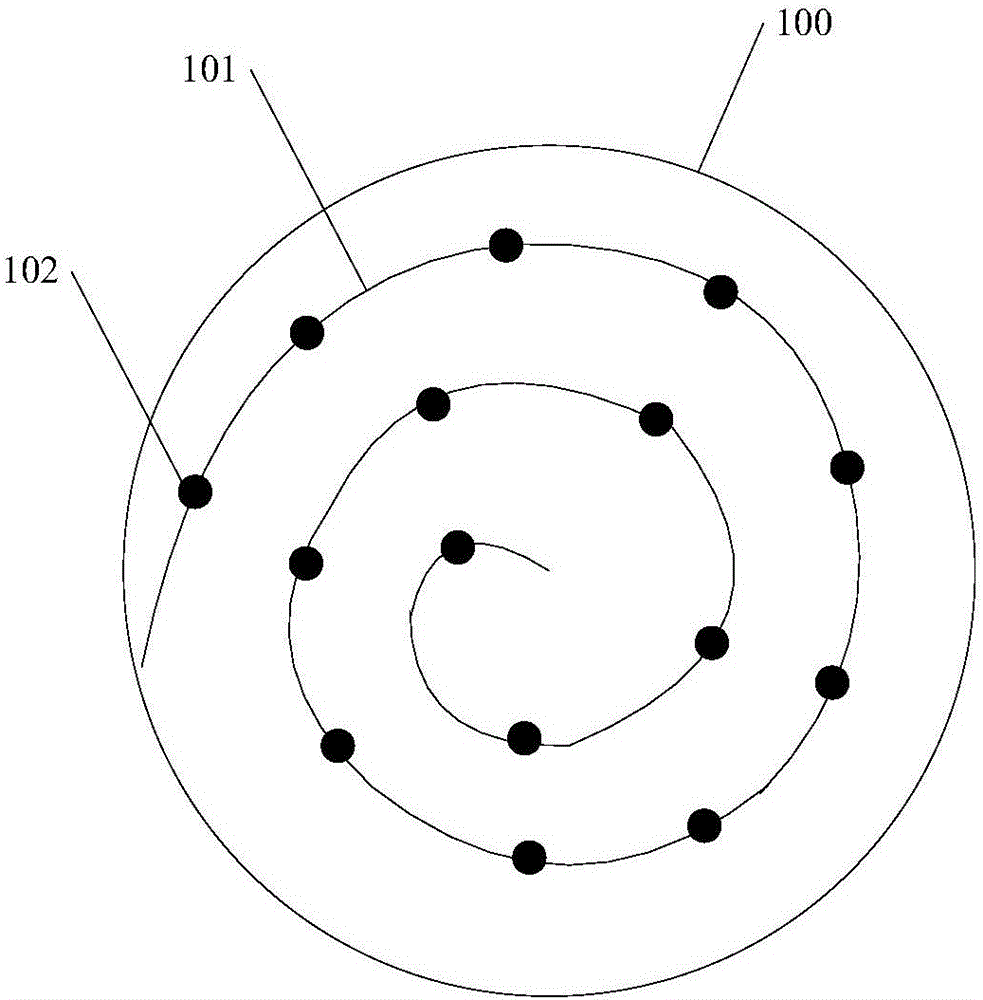

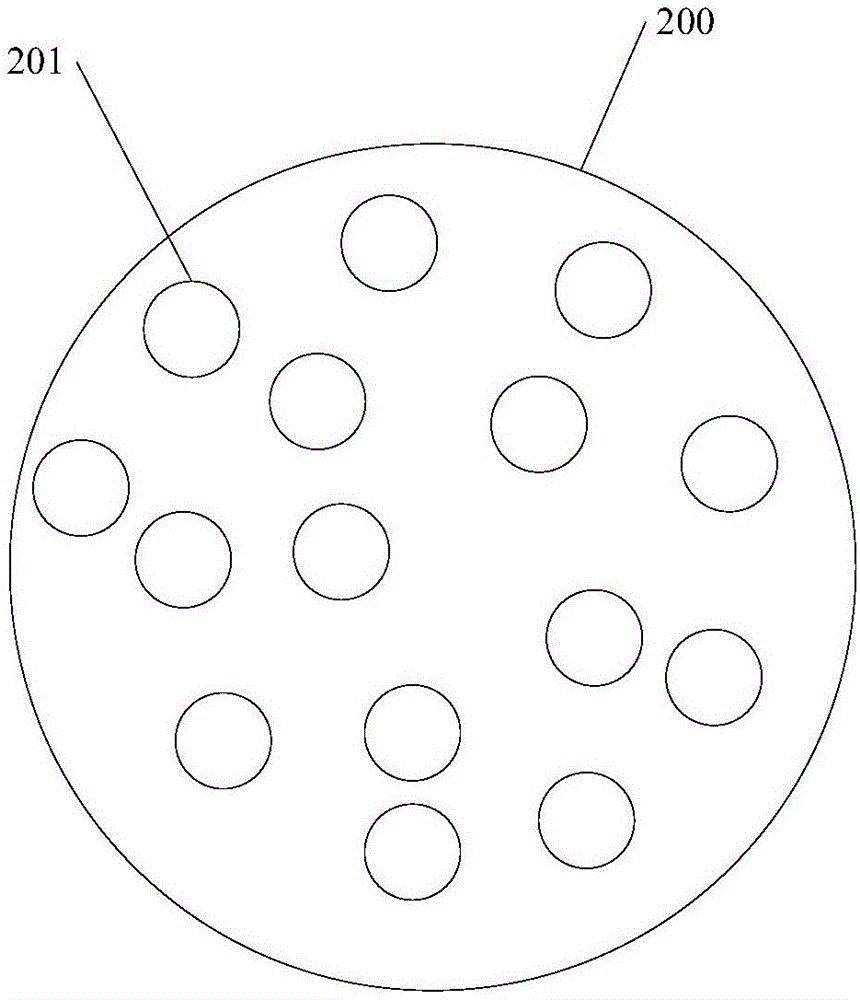

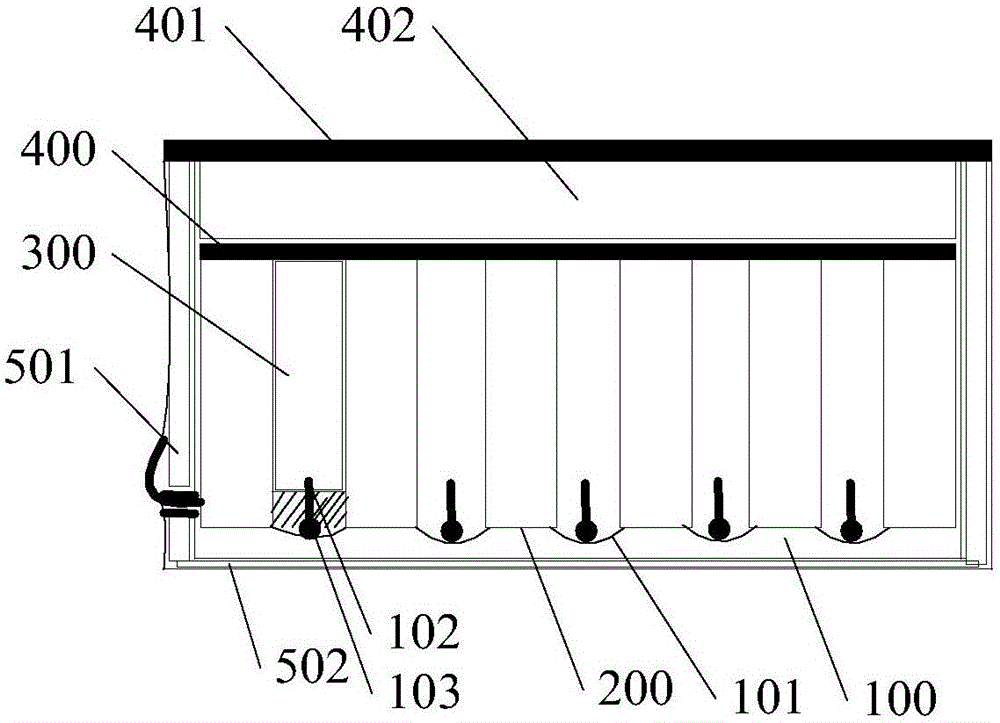

[0035] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a kind of integrated production method of firecrackers, comprising the following steps:

[0036] Step 1. Use the mixture of pond mud and crushed straw to press in the first cylindrical mold to form a base 100 with a groove 101 with a vortex structure at the upper end. The depth of the groove is less than 5 mm, and dry until the water content is lower than 5 mm. After %, spare; the groove of the spiral structure provides accommodating space for the laying of the lead wire, and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com