Polycarbonate compositions having infrared absorbance, method of manufacture, and articles prepared therefrom

A technology of polycarbonate resin and composition, applied in prosthetics, transportation and packaging, goggles, etc., which can solve the problems of lack of thermal and oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

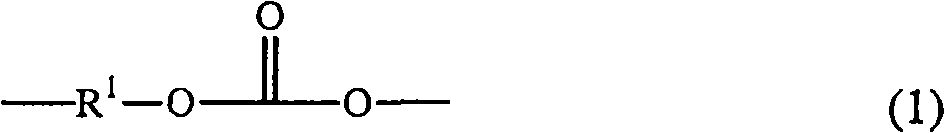

Method used

Image

Examples

Embodiment 1

[0146] Example 1 and Comparative Examples 1 and 2. Use selected LaB 6 (All) and Carbon Black (Example 1) Contents The following examples and comparative examples were prepared to demonstrate the balance of characteristics between meeting EN 171 requirements and MVR performance. The results of the spectral requirements of the examples and comparative examples are summarized as pass or fail (EN 171).

[0147] Table 2

[0148] Example 1 a

Comparative example 1 a

Comparative example 2 a

LaB 6 (g / m 2 )

0.48

1.56

0.48

CB(g / m 2 )

0.24

0

0

EN 171 requirements (level: 5) b

Qualified

Qualified

Unqualified

MVR at 300℃ and 12Kg

(cc / 10min)

7

10

7

[0149] a All examples and comparative examples are 1.0 mm thick.

[0150] b EN 171 level 5 requirements are: maximum light transmittance of 3.2%, minimum of 1.2%; maximum average spectral transmittance in infrared...

Embodiment 4

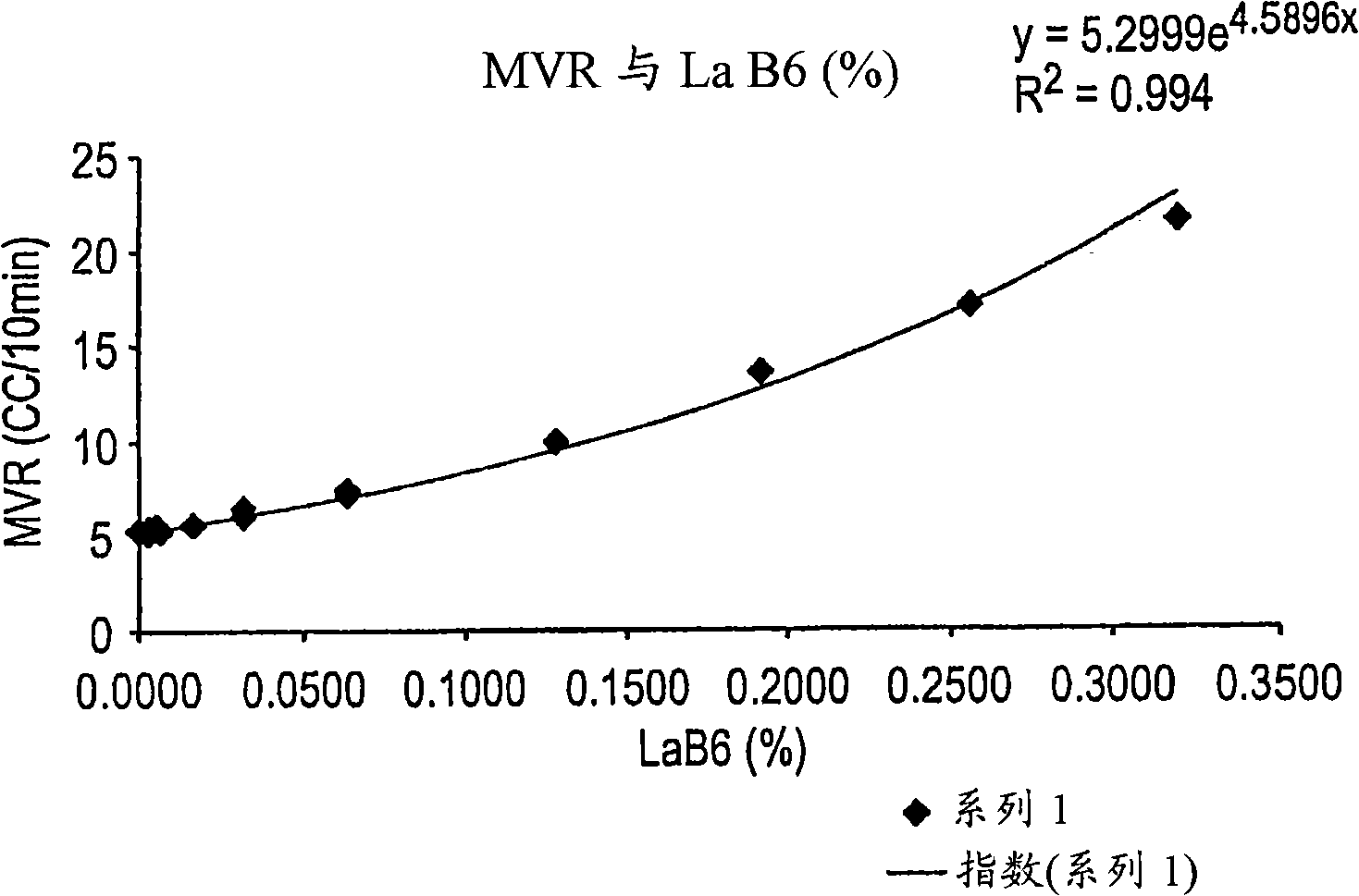

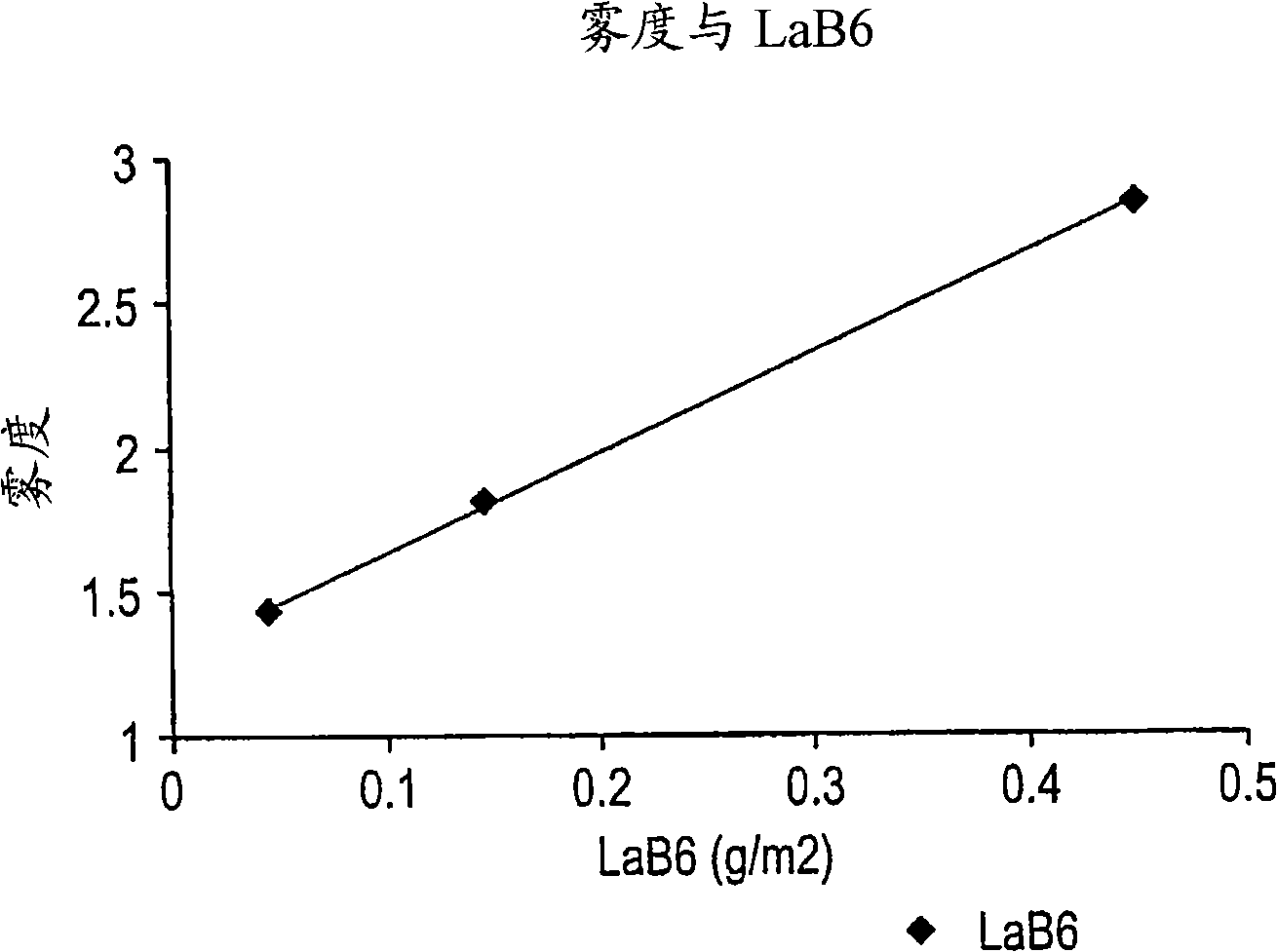

[0161] Example 4: Determination of LaB suitable for a composition meeting the requirements of EN 169 and / or EN 171 6 And the method of carbon black content. The transfer function has been developed to estimate the carbon black and LaB required to meet the specific UV, VIS and IR transmittance requirements in EN 169 and / or EN 171 6 Level. The transfer function is derived from a set of experiments (1mm) given in Table 4:

[0162] Table 4

[0163]

Recipe number f

LaB 6 (g / m 2 )

C.B.(g / m 2 )

Average %T VIS

780-1400nm

The average %T NIR

780-2000nm

The average %T NIR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

0.06575

0.033625

0.06575

0.0015

0.033625

0.06575

0.0015

0.033625

0.0015

0.0015

0.06575

0.0015

0.05

0.06

0.04

0.05

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com