Pressureless pipe comprising a multimodal polyethylene composition with an inorganic filler

A composition, polyethylene technology, applied in the field of pipe manufacturing, can solve problems such as insufficient welding strength, and achieve the effects of low creep, good weldability, and high crack growth resistance

Inactive Publication Date: 2008-09-10

ボレアリステクノロジーオイ

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Weld strength is known to be generally insufficient especially for filled polymer compositions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

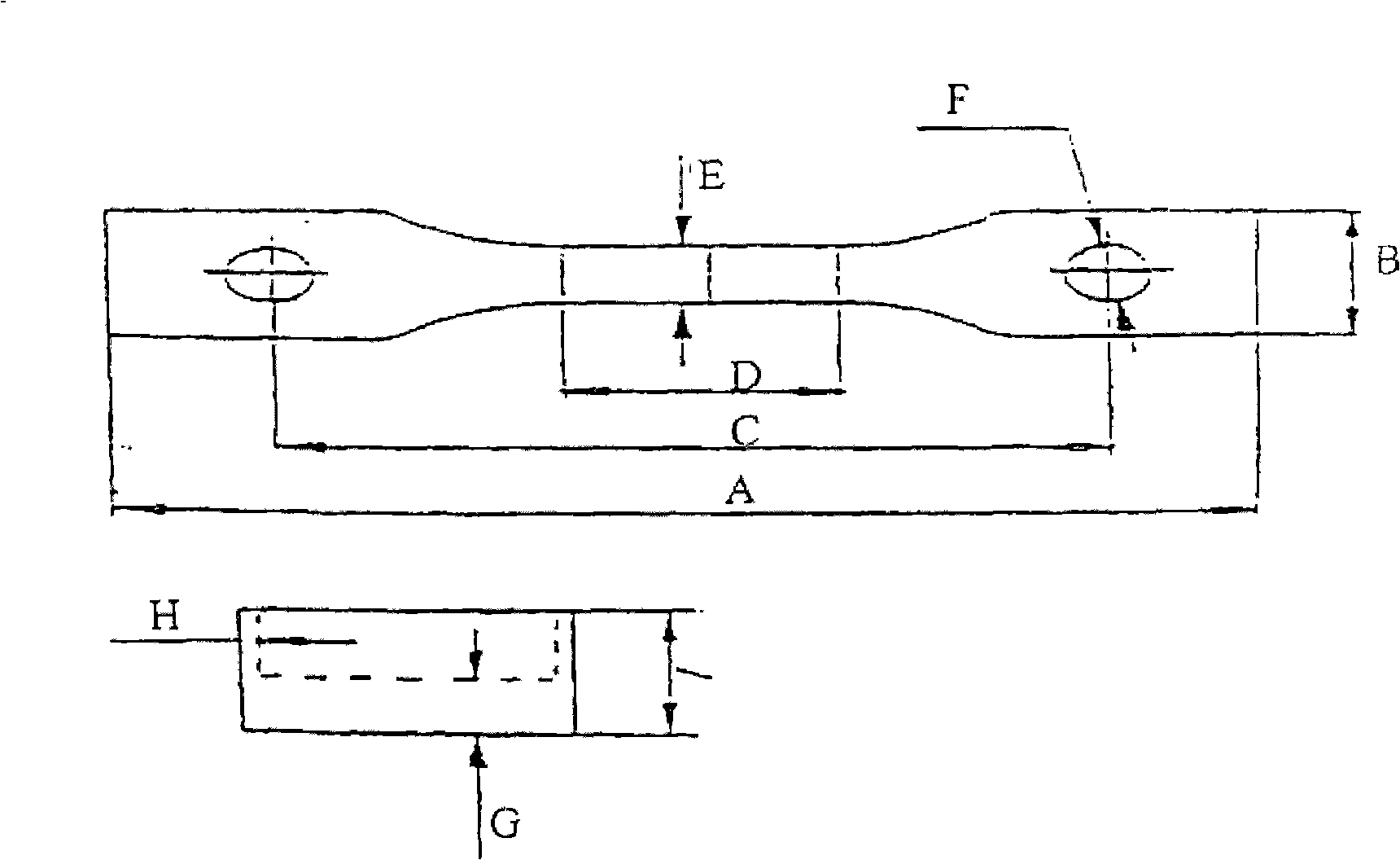

[0113] 1. Definition and measurement method

[0114] a) Density

[0115] Density is measured according to ISO 1183 / ISO 1872-2B.

[0116] b) Melt flow rate / flow rate ratio

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

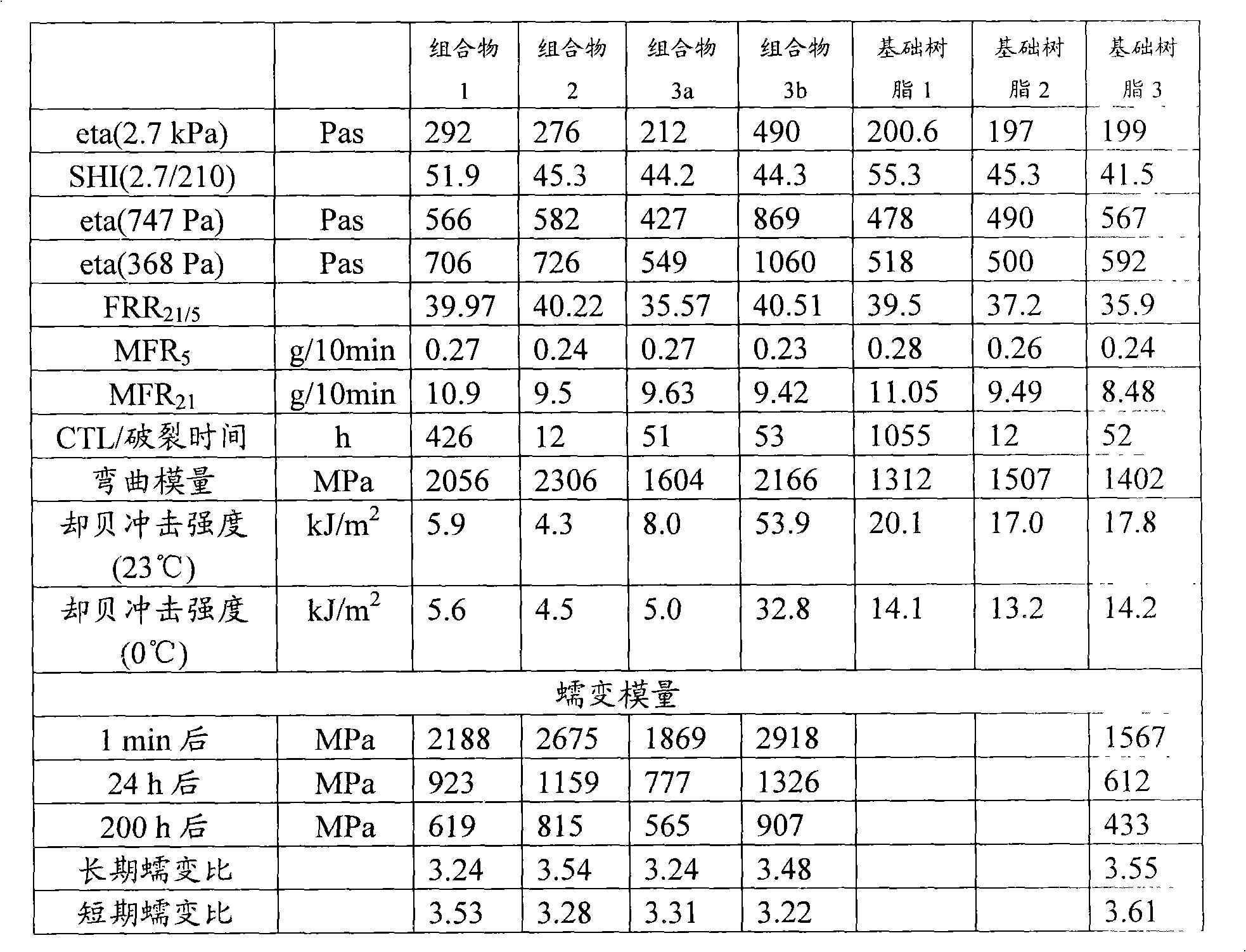

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a pipe or a supplementary pipe article comprising a polyethylene composition comprising a base resin which comprises (A) a first ethylene homo- or copolymer fraction, and (B) a second ethylene homo- or copolymer fraction, wherein fraction (A) has a lower average molecular weight than fraction (B), the base resin has a flexural modulus determined according to ISO 178 of 1000 MPa or higher, and the composition further comprises (C) an inorganic mineral filler, wherein inorganic mineral filler (C) is present in the composition in an amount of 1 to 70 wt. %, and to the use of said composition for the production of a pipe or a supplementary pipe article.

Description

technical field [0001] The present invention relates to a pipe, and more particularly to a pipe for conveying unpressurized fluids, said pipe comprising a polyethylene composition comprising a polyethylene base resin and an inorganic mineral filler. Furthermore, the invention relates to the use of said composition for the manufacture of pipes. Background technique [0002] Polyethylene compositions are often used in the manufacture of pipes due to their good physical and chemical properties such as mechanical strength, corrosion resistance and long-term stability. For example, when conveying tap water or natural gas, the fluid conveyed in the pipe can be pressurized; The fluid conveyed in the tubing may be unpressurized when removing dirt and waste. The fluid conveyed within the tubing may have varying temperatures, typically in the range of 0°C to 50°C. [0003] In particular, the invention relates to tubing for conveying unpressurized fluids. Such pipes are often refer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/04C08L23/08C08K3/00

CPCC08F210/16C08L23/06C08L23/0815C08L2205/02C08L2308/00F16L9/12Y10T428/1352Y10T428/1397Y10T428/139Y10T428/31855C08L2666/04C08L2666/06C08F210/14C08F2500/12C08F2500/13C08F2500/17C08F4/6492C08F2/001C08K3/00C08L23/08C08L23/04

Inventor 卡拉-吉斯塔夫·埃克马茨·贝克曼

Owner ボレアリステクノロジーオイ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com