Nonaqueous electrolyte for improving performance and lithium secondary battery comprising the same

一种锂二次电池、电解质的技术,应用在非水电解质蓄电池、电解质蓄电池制造、二次电池等方向,能够解决锂二次电池性能降低、电池安全性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the manufacture of lithium secondary battery

[0049] with LiCoO 2 As a cathode active material, a conductive agent and a binder are added to NMP (N-methyl-2-pyrrolidone) along with the cathode active material, thereby forming a cathode slurry. Next, the cathode slurry was coated on an aluminum (Al) current collector to provide a cathode.

[0050] The specific surface area is 1.5m 2 / g of artificial graphite is used as the anode active material, and the conductive agent and the binder are added to the NMP together with the anode active material to form the anode slurry. Next, the anode slurry was coated on a copper (Cu) current collector to provide an anode.

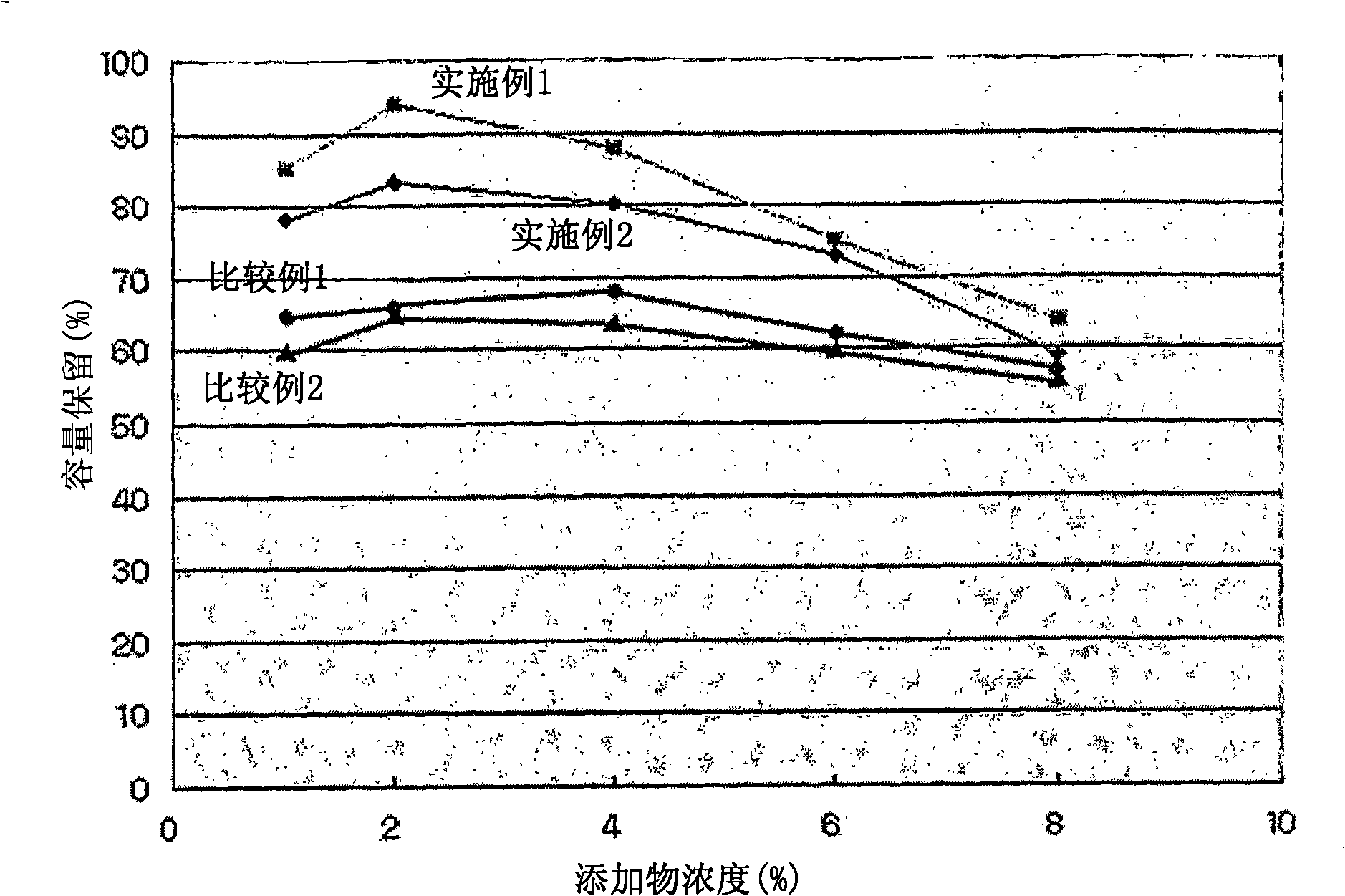

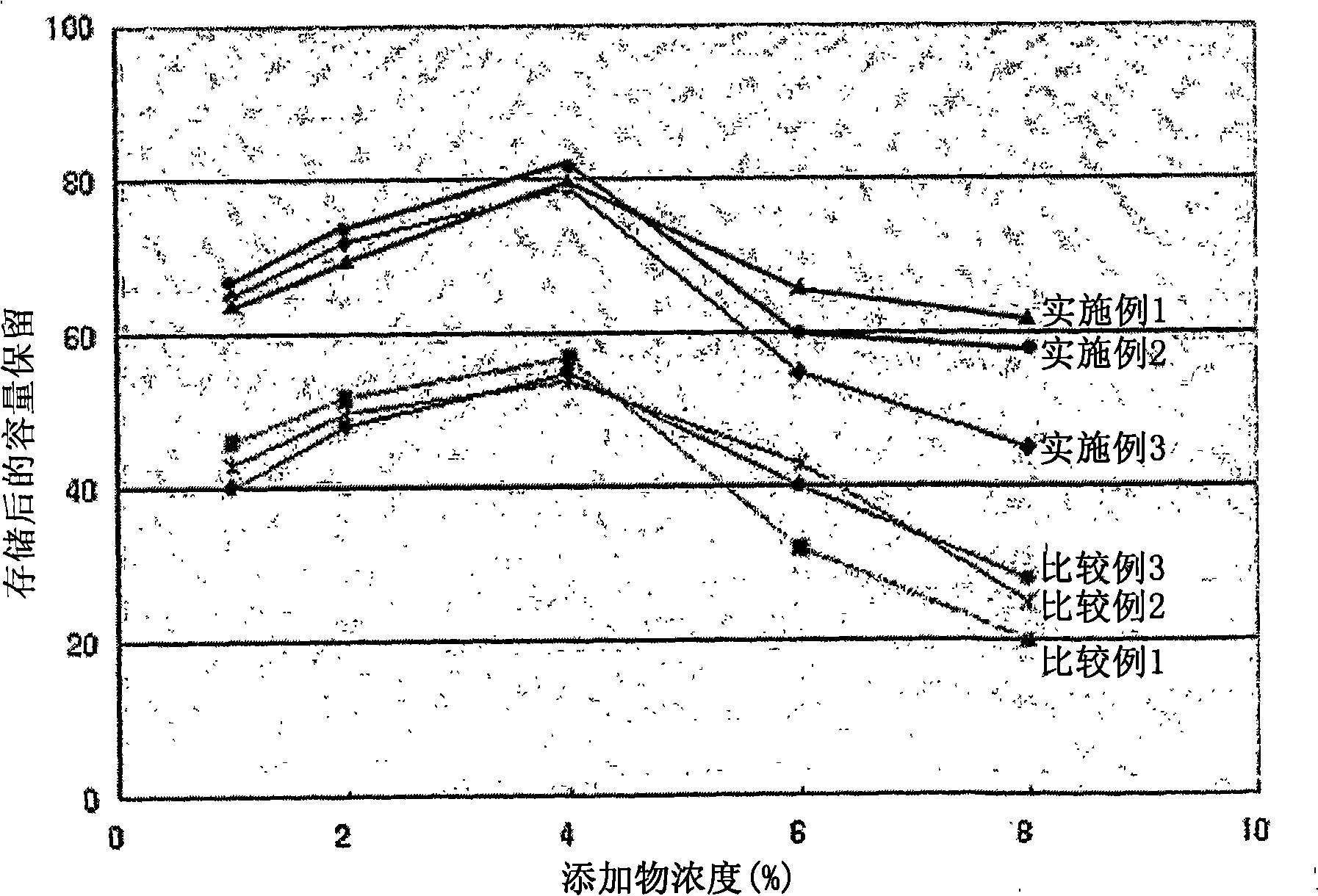

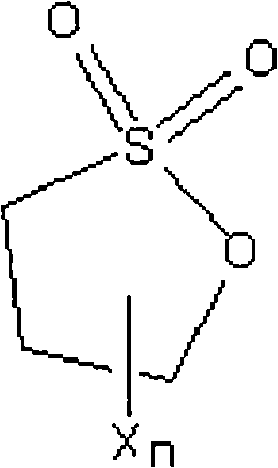

[0051] Use contains 1M LiPF 6 The EC / EMC-based solution dissolved therein was used as an electrolyte, and 1, 2, 4, 6, and 8 parts by weight of fluoropropane sultone (FPS, X=F) were added to the electrolyte.

[0052] A polyolefin-based separator was interposed between the above-obtained cathode a...

Embodiment 2

[0054] A lithium secondary battery was provided in the same manner as in Example 1 except that PS was used in the electrolyte instead of FPS.

Embodiment 3

[0056] A lithium secondary battery was provided in the same manner as in Example 1 except that cyanopropane sultone (CNPS, X=CN) was used in the electrolyte instead of FPS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com