Straight welded pipe millet-shaped measuring apparatus and method

A technology of straight seam welded pipe and measuring device, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve problems such as inability to measure, and achieve the effect of convenient operation and maintenance and high numerical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

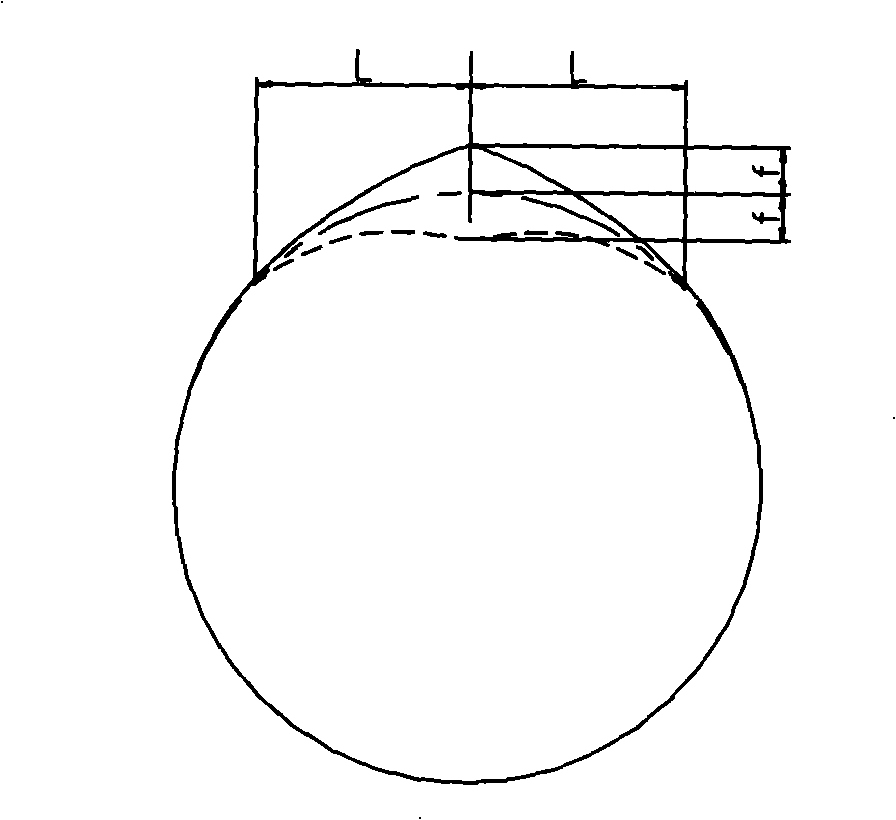

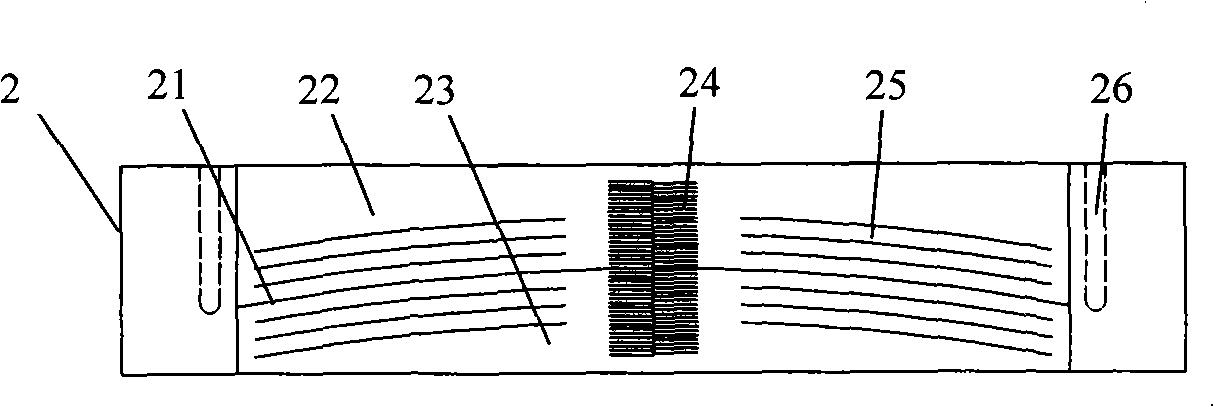

[0023] By definition, a chestnut shape is the deviation of an actual irregular shape from an ideal circular arc under certain conditions. Therefore, simulating the theoretical shape of a section of circular arc of steel pipes with different outer diameters and collecting the actual shape are the main objects of research. Accordingly, the measuring device of the present invention is composed of a measuring plate and a template, which are respectively used for collecting the actual shape and simulating the theoretical arc.

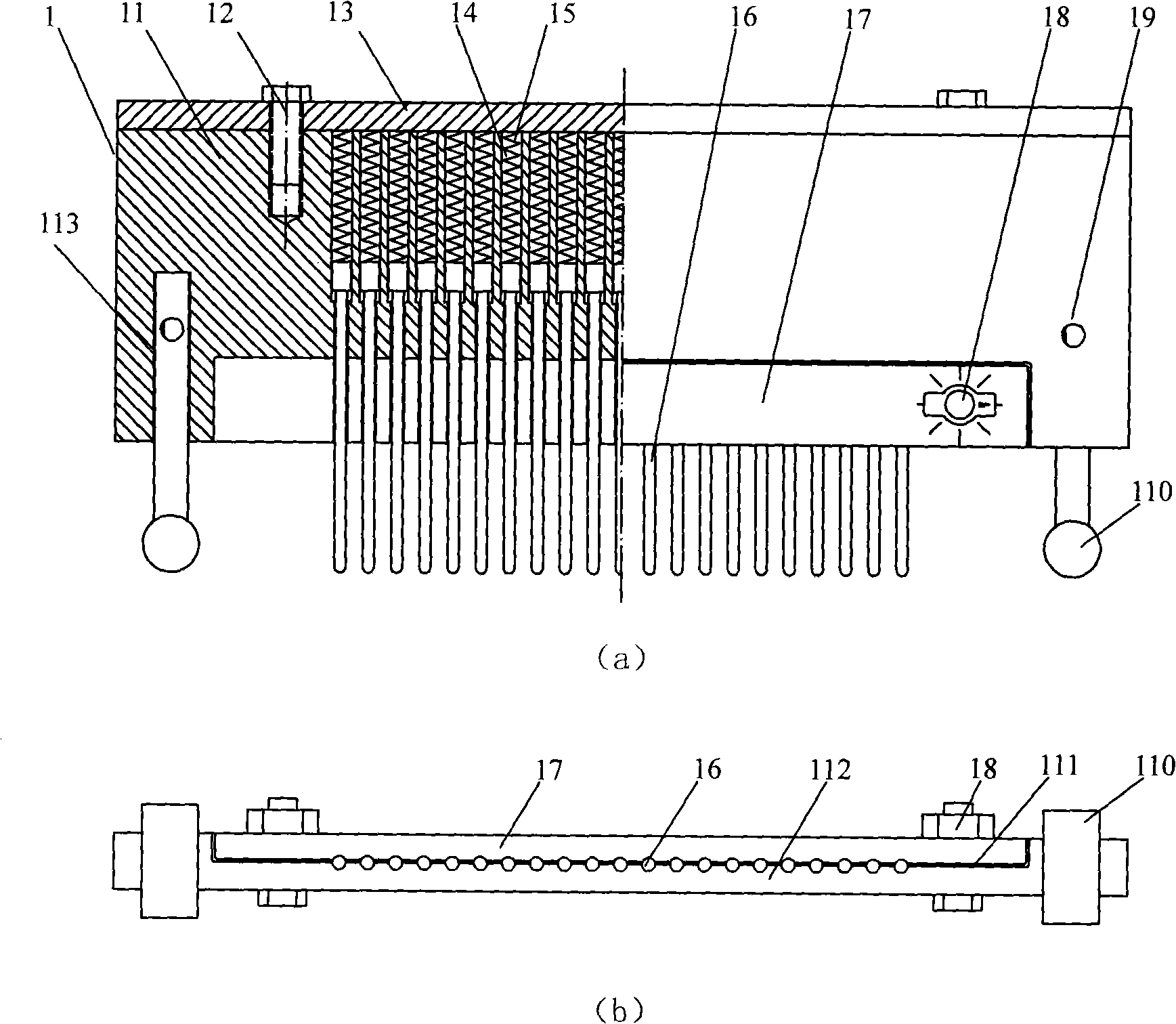

[0024] Only one kind of measuring board is needed, which is used to collect the actual shape of the chestnut shape of the steel pipe. figure 2 (a) is a schematic diagram of the structure of the measuring board, figure 2 (b) for figure 2 (a) Schematic diagram of looking up. As shown in the figure, the measurement board 1 includes a main board 11 , a top board 13 , a thimble 16 , and a clamping board 17 .

[0025] There are several guide slots 14 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com