Center loop mechanism in plane segmenting product line rotary device

A technology of rotating device and plane segmentation, which is applied to auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of labor intensity of workers, improving safety and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

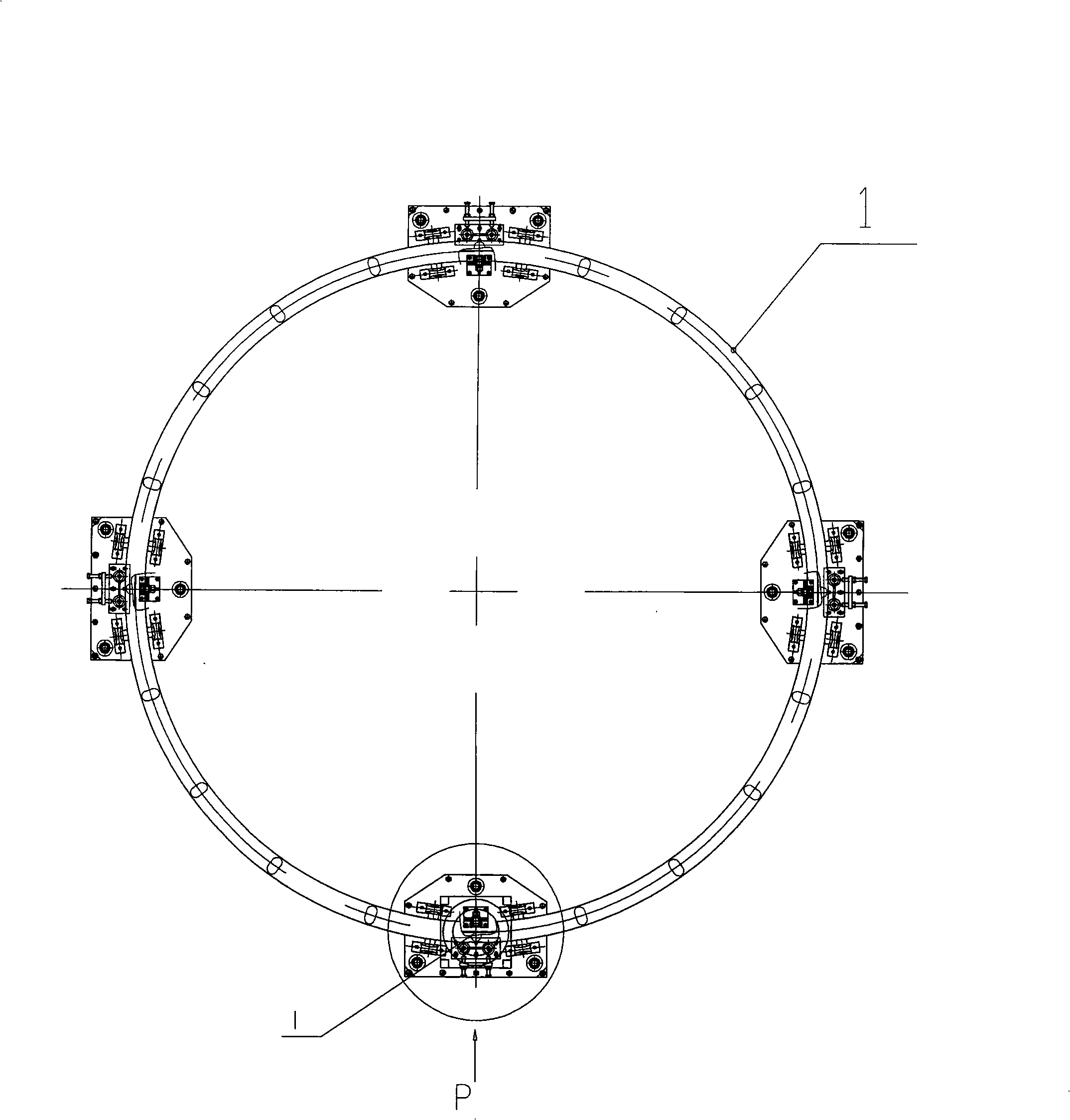

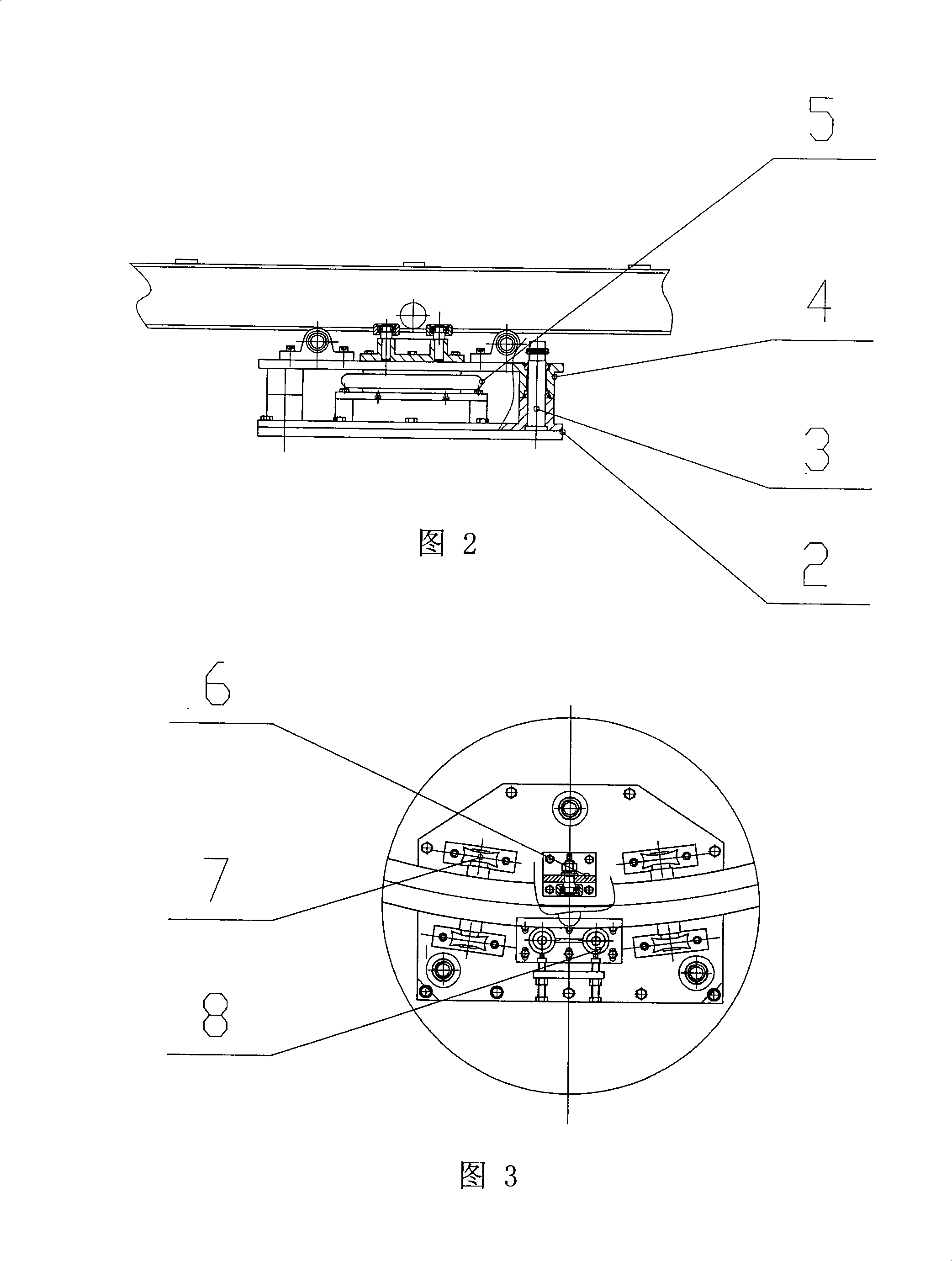

[0012] The present invention is mainly made up of rotating ring 1, fixed seat 2, guide rod 3, lifting seat 4, airbag type cylinder 5, inner positioning wheel 6, small cylinder 7 and outer positioning wheel 8, etc.

[0013] like figure 1 As shown in Figure 3, the present invention includes a rotating ring 1, and 2 to 8 groups of rotating seat assemblies are evenly arranged on the circumference of the rotating ring 1. The rotating seat assembly includes a fixed seat 2, a guide rod 3, a lifting seat 4, an airbag cylinder 5, an inner positioning wheel 6, a small roller 7 and an outer positioning wheel 8, etc., and the fixed seat 2 is equipped with a guide rod 3 and the airbag type cylinder 5, the lifting seat 4 is enclosed within on the guide bar 3, and the inside positioning wheel 6, the small cylinder 7 and the outside positioning wheel 8 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com