Decorative panel and method of manufacturing the same

A technology for decorative panels and manufacturing methods, applied in decorative arts, special decorative structures, chemical instruments and methods, etc., can solve problems such as monotony, increase manufacturing costs, waste materials, etc., so as to reduce manufacturing costs, save materials, and improve sales opportunities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

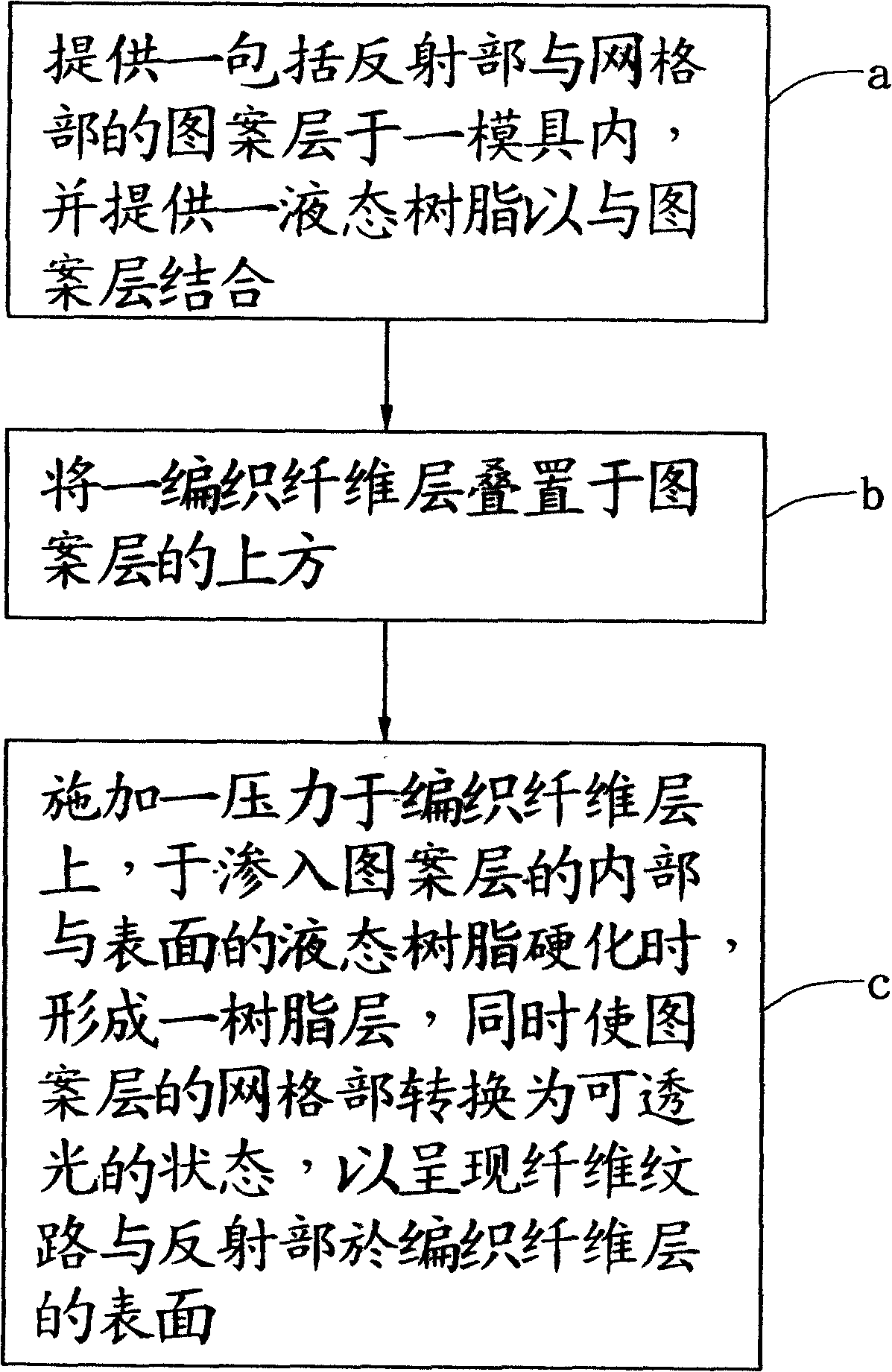

[0022] see figure 1 Shown, it is the preferred embodiment of the manufacturing method of decorative panel of the present invention, mainly comprises the following steps:

[0023] providing a pattern layer including a reflective part and a grid part in the mold, and providing liquid resin to combine with the pattern layer;

[0024] laminating a woven fiber layer over the pattern layer; and

[0025] Applying pressure on the woven fiber layer, when the liquid resin infiltrated into the interior and surface of the pattern layer hardens, the resin layer is formed, and at the same time, the grid part of the pattern layer is converted into a light-transmitting state, so that the surface of the decorative panel presents a reflective part The metallic luster and the fiber texture of the woven fiber layer.

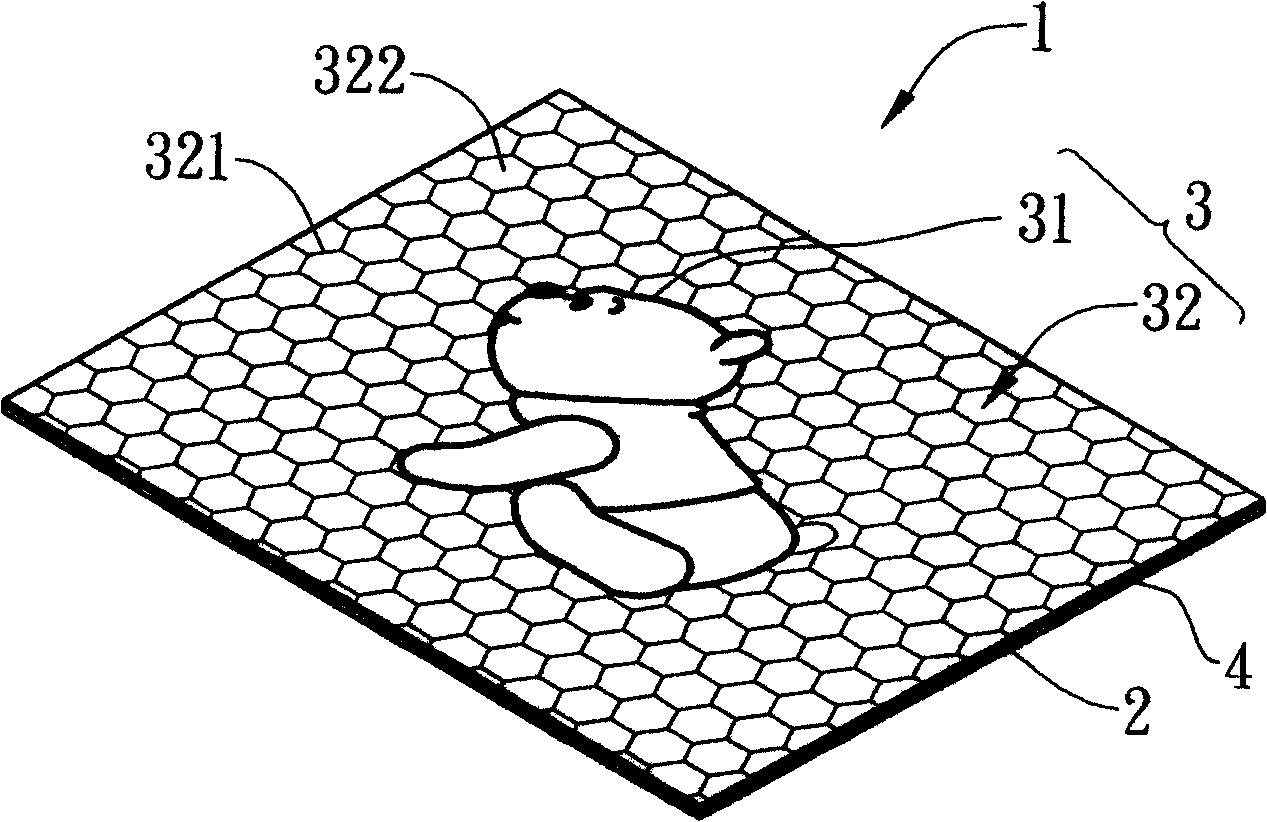

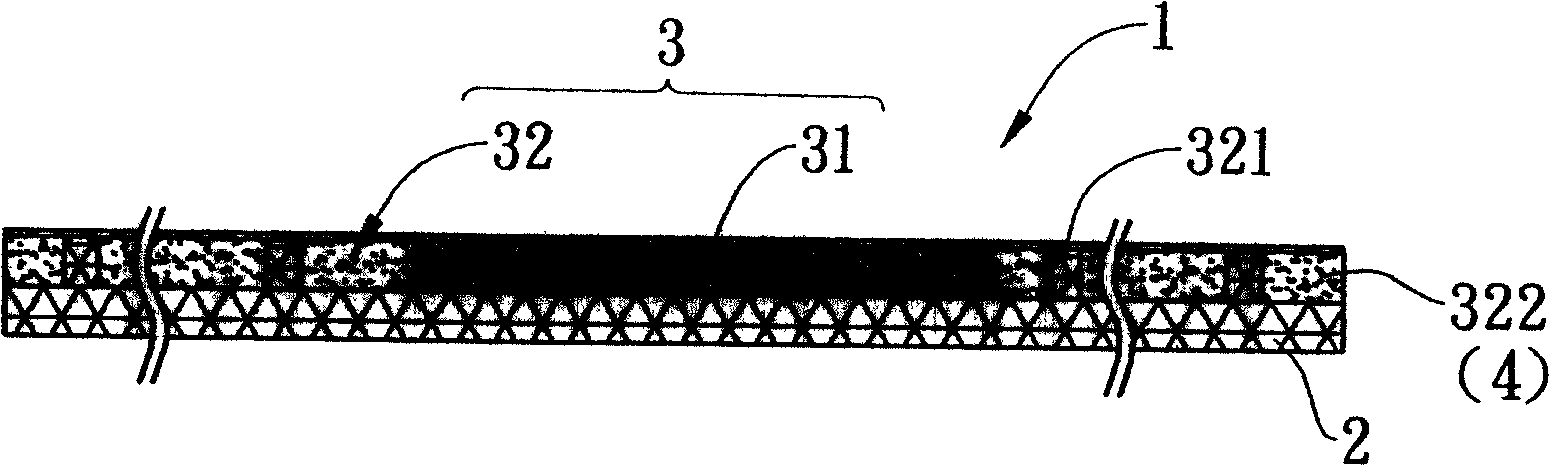

[0026] see figure 2 As shown, in the above step b, the liquid resin is added to the pattern layer 3 from the outside of the mold (not shown in the figure), and the pattern layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com