Portable oxygen generator

An oxygen generator, portable technology, applied in the field of oxygen production equipment, can solve the problems of complex structure, inconvenient use, high cost, etc., and achieve the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

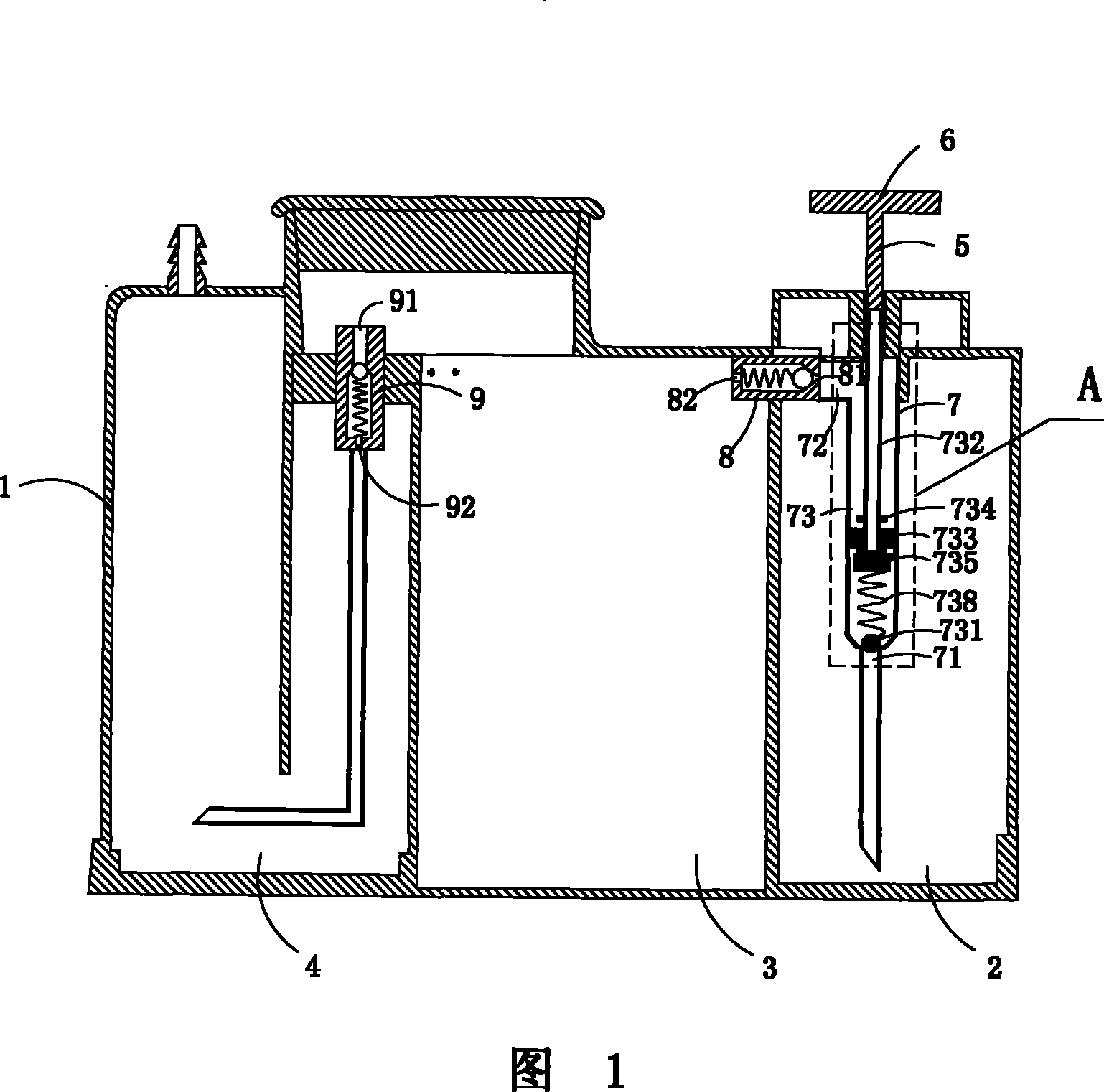

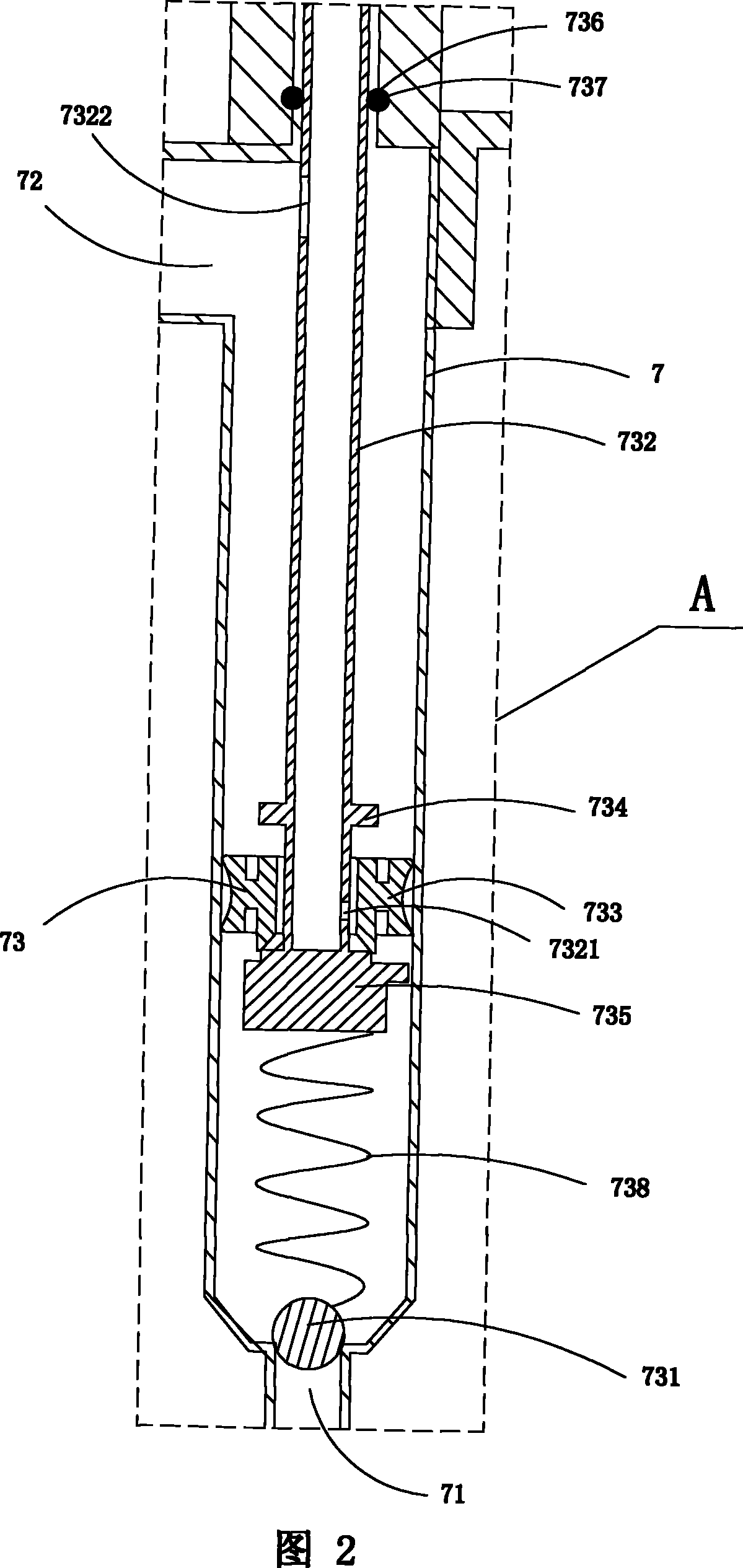

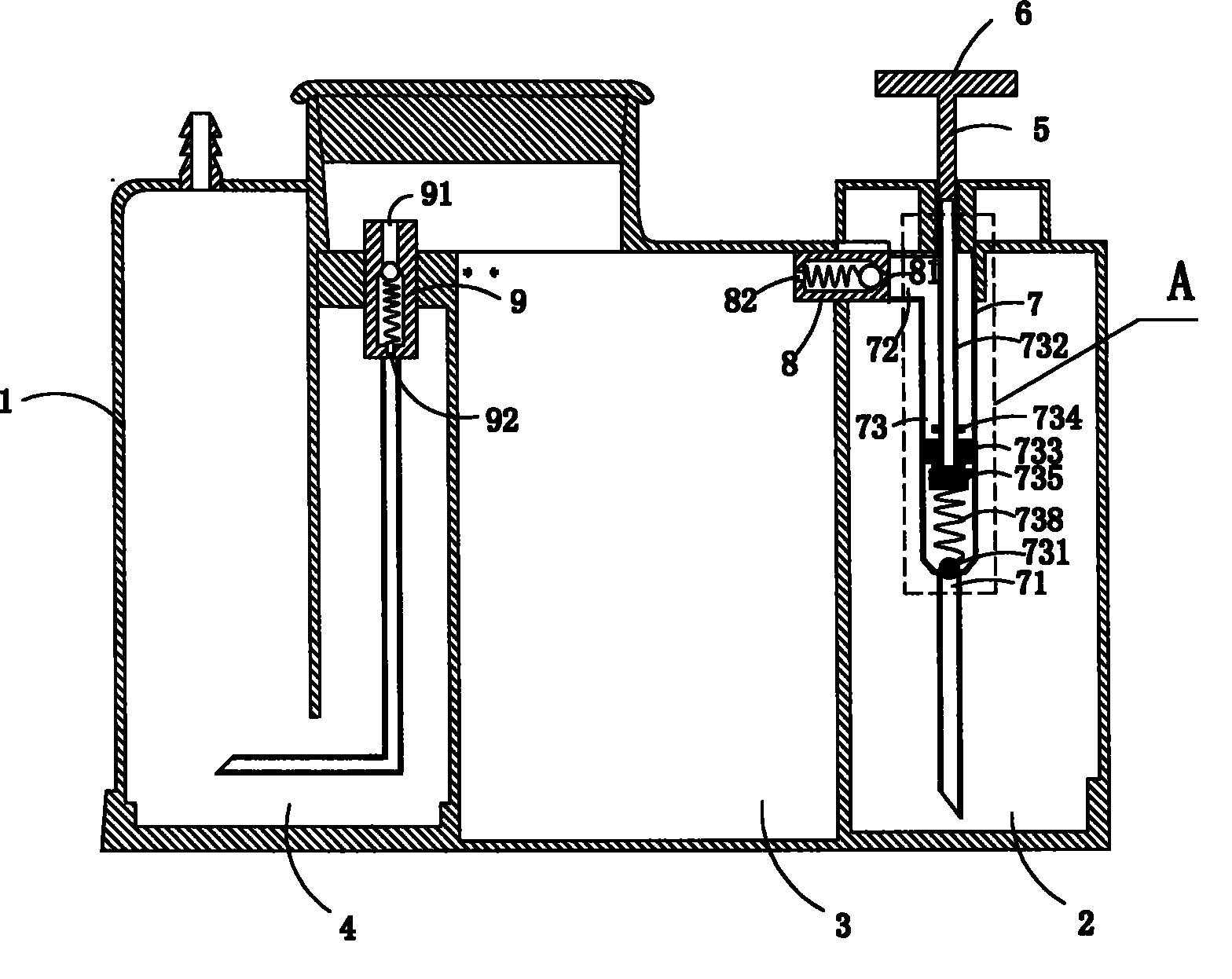

[0025] Figures 1 and 2 show the first specific embodiment of the present invention, wherein Figure 1 is a schematic cross-sectional view of the first structure of the present invention; Figure 2 is an enlarged schematic view of the local structure at A in Figure 1 .

[0026] This embodiment is a portable oxygen generator, see Fig. 1 and Fig. 2, comprise housing 1, liquid storage chamber 2, catalytic reaction chamber 3, humidification chamber 4, and be used for pumping the liquid in liquid storage chamber 2 into catalytic The suction device 5 in the reaction chamber 3 communicates with the liquid storage chamber 2, the catalytic reaction chamber 3, and the humidification chamber 4 in sequence.

[0027] Said suction device 5 comprises a suction handle 6 and a liquid suction tube 7; said liquid suction tube 7 comprises a liquid inlet 71, a liquid outlet 72, and a tube arranged in the pipe body for drawing liquid from the liquid inlet. 71 is sucked in and discharged from the liqui...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, except that: the humidification chamber 4 is provided with a flow control valve for controlling the discharge of oxygen; Can breathe oxygen.

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 2, except that the catalytic reaction chamber 3 is also provided with an explosion-proof safety valve. If the oxygen generation rate in the catalytic reaction chamber 3 is too fast, the air pressure will rise sharply. After the preset pressure of the valve is reached, the airflow is discharged from the explosion-proof safety valve to the atmosphere, thereby achieving the effect of explosion-proof protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com