Ultra-large span three-dimensional pre-stress beamless circular plate construction method

A three-way prestressing and construction method technology, applied in construction, building construction, etc., can solve problems such as construction difficulties, formwork damage, waste of funds, etc., to achieve quality and structural safety savings, guarantee construction period, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

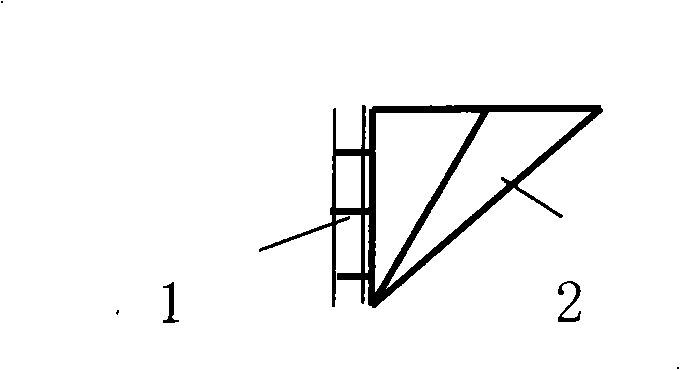

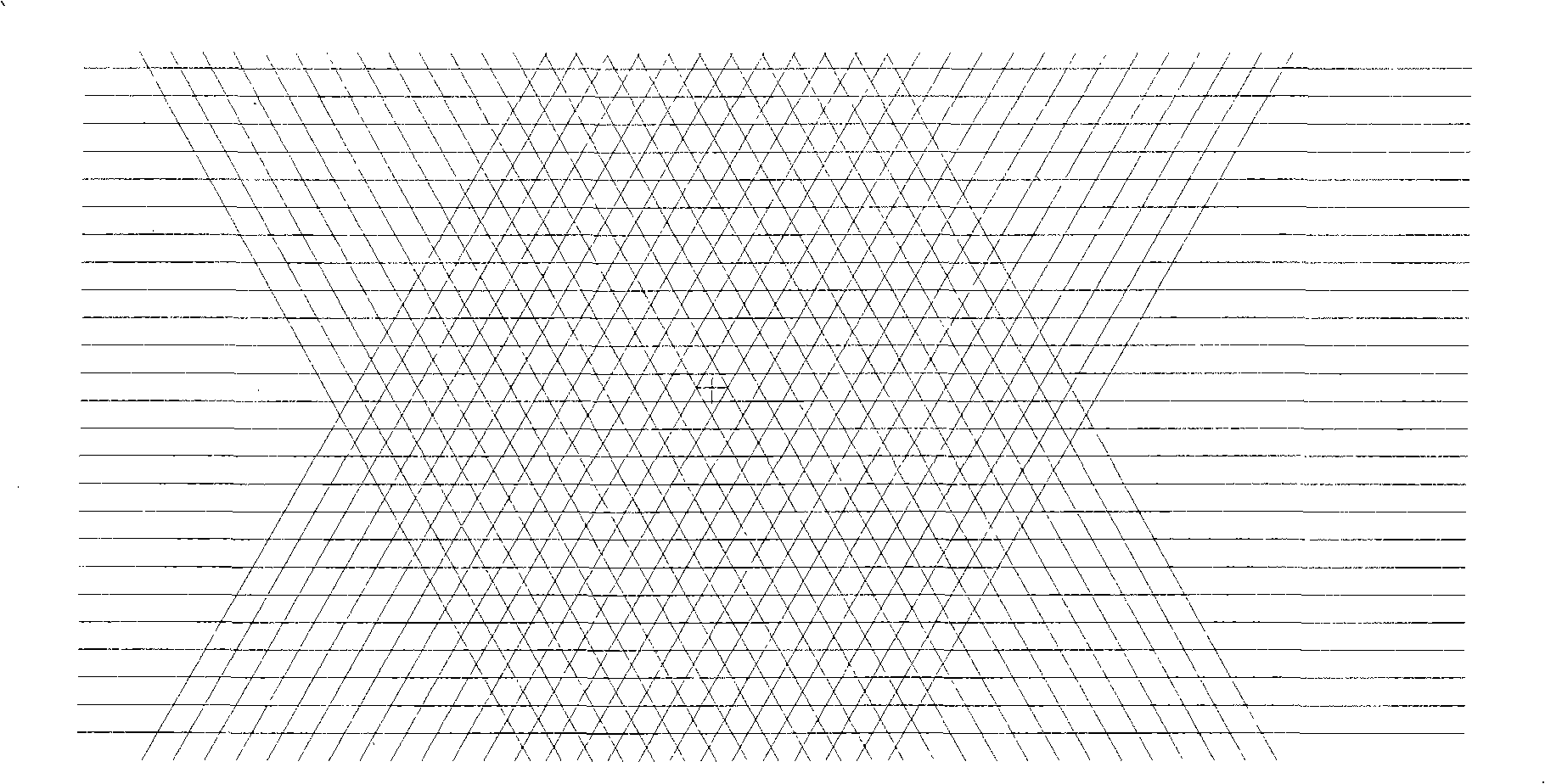

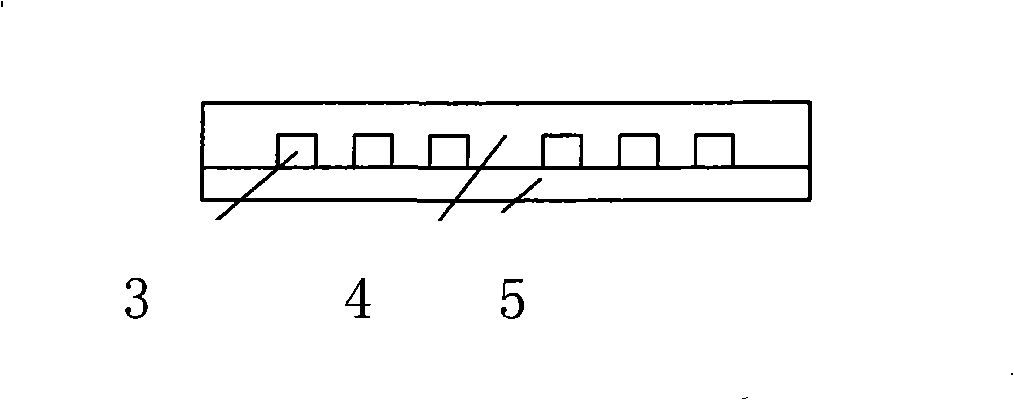

Embodiment 1

[0027] (a) preparing a plurality of prestressed steel bars with a length of 300mm exposed on the outer edge of the concrete slab, the prestressed steel bars adopt low-relaxation steel strands, and the steel strands are bundled, and each The tension ends and the anchor ends in the bundle are arranged alternately; (b) use erection steel pipes as oblique rods and upper horizontal rods and pull bolts on the cylinder wall to form a triangular bracket; (c) lay circular plates on the triangular brackets Bottom mold, the laying sequence is to lay the bottom mold template in the middle of the circular plate first, then support the armpit template, and finally lay the bottom mold on the edge of the circular plate. The size is 0.9m, and the middle bottom formwork is ridged according to the vertical axis to ensure that the highest arching height of the central point is 3‰ of the span; Lay the ordinary reinforcing bars at the bottom of the unequal long plate at the bottom edge of the circu...

Embodiment 2

[0030] (a) preparing a plurality of prestressed steel bars with a length of 400mm exposed on the outer edge of the concrete slab, the prestressed steel bars adopt low-relaxation steel strands, and the steel strands are bundled, and each The tension ends and the anchor ends in the bundle are arranged alternately; (b) use erection steel pipes as oblique rods and upper horizontal rods and pull bolts on the cylinder wall to form a triangular bracket; (c) lay circular plates on the triangular brackets Bottom mold, the laying sequence is to lay the bottom mold template in the middle of the circular plate first, then support the armpit template, and finally lay the bottom mold on the edge of the circular plate. The size is 0.95m, and the middle bottom formwork is ridged according to the vertical axis to ensure that the highest arching height of the central point is 3‰ of the span; Lay the ordinary reinforcing bars at the bottom of the unequal long plate at the bottom edge of the circ...

Embodiment 3

[0033](a) preparing a plurality of prestressed steel bars with a length of 200mm exposed on the outer edge of the concrete slab, the prestressed steel bars adopt low-relaxation steel strands, and the steel strands are bundled, and each The tension ends and the anchor ends in the bundle are arranged alternately; (b) use erection steel pipes as oblique rods and upper horizontal rods and pull bolts on the cylinder wall to form a triangular bracket; (c) lay circular plates on the triangular brackets Bottom mold, the laying sequence is to lay the bottom mold template in the middle of the circular plate first, then support the armpit template, and finally lay the bottom mold on the edge of the circular plate. The size is 1.0m, and the middle bottom formwork formwork is ridged according to the vertical axis to ensure that the arching height at the highest point of the center point is 3‰ of the span; Lay the ordinary reinforcing bars at the bottom of the unequal long plate at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com