Method and system for vibration signal processing

A technology of vibration signal and processing method, which is applied in the direction of measuring vibration, vibration measurement in solids, instruments, etc., and can solve problems such as enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

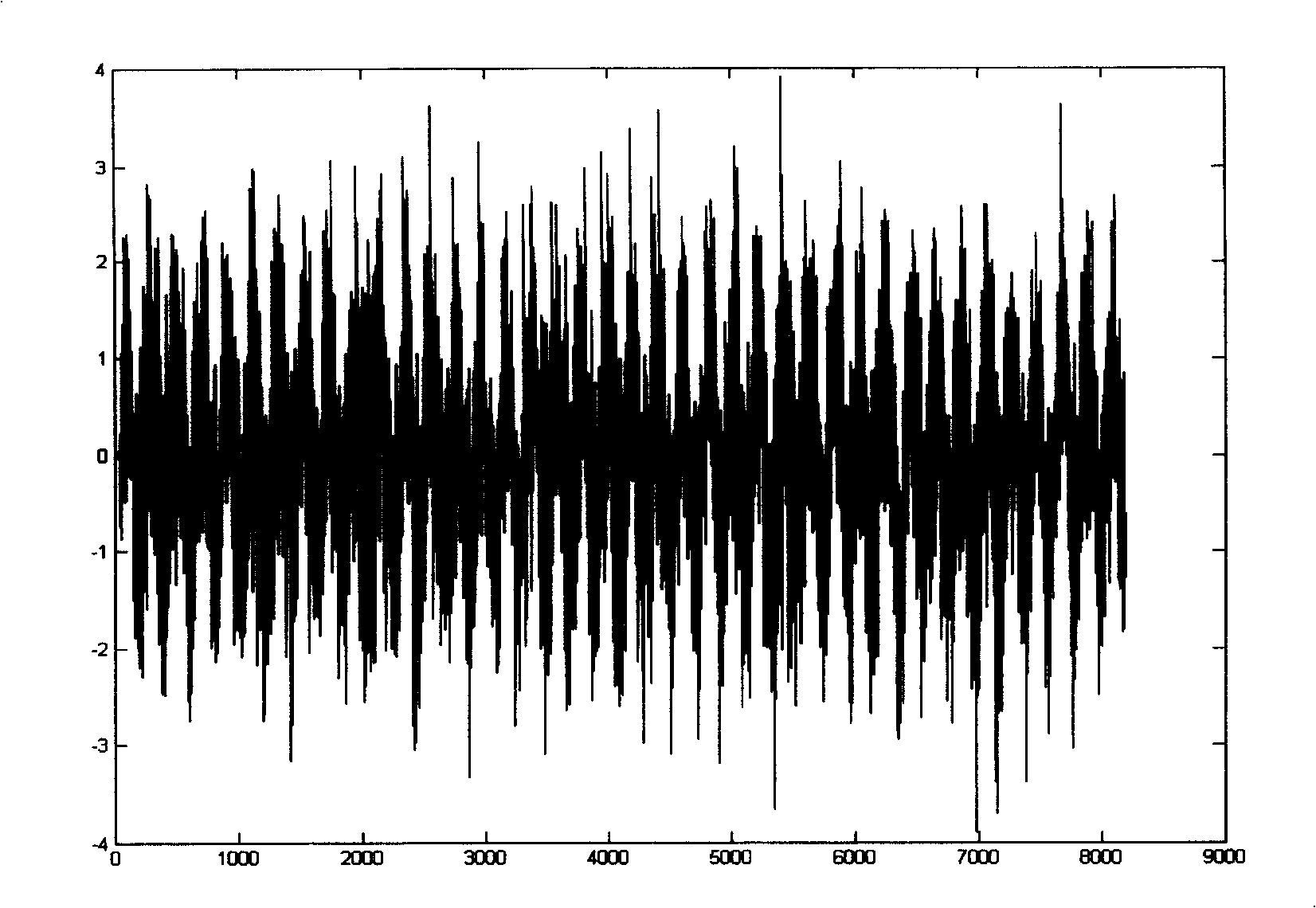

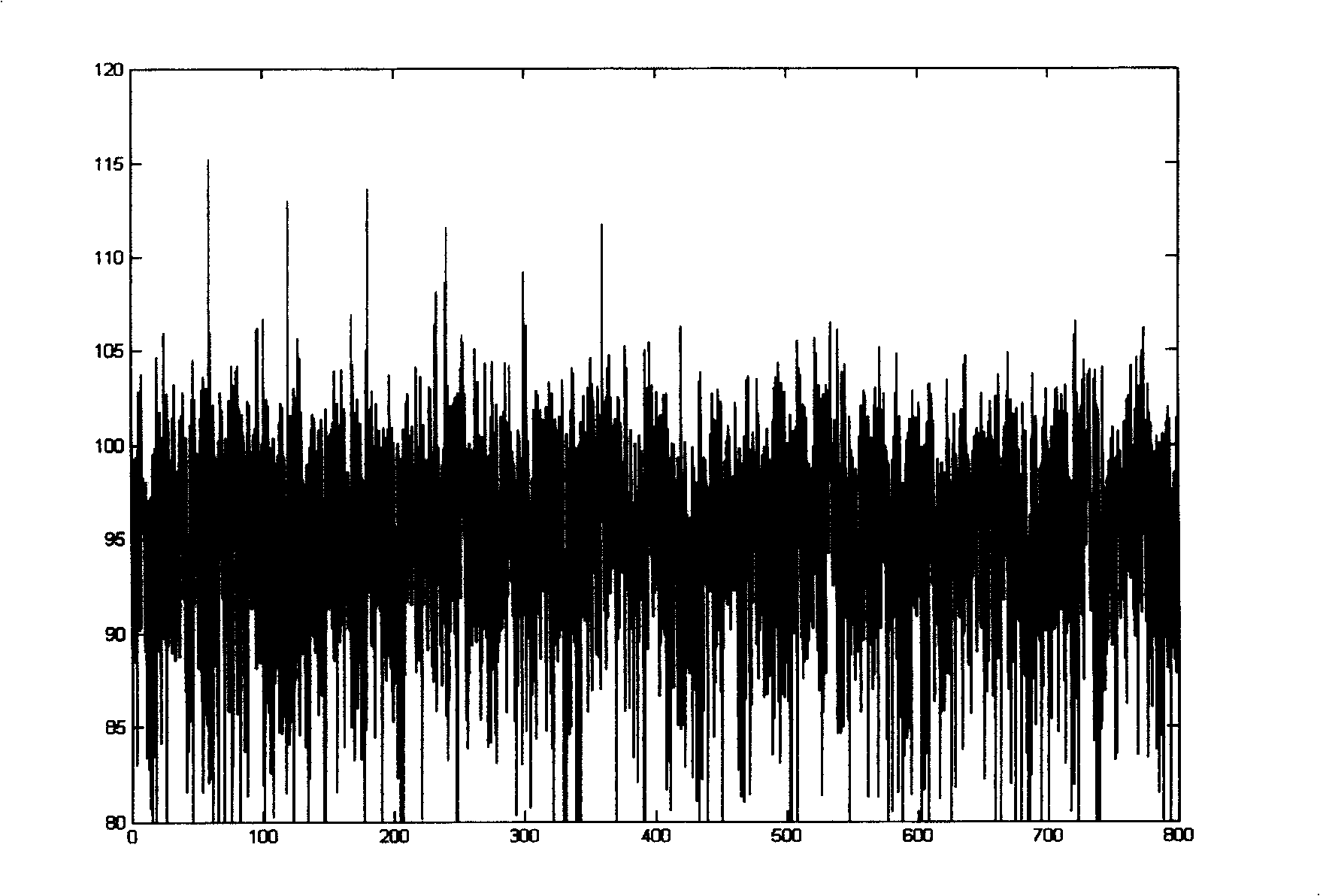

[0039] The present invention relates to vibration signal analysis that can be used to account for bumps or squeezes hidden in normal vibrations read by low frequency vibrations and high frequency noise. By using the noise vibration signal technique of the present invention, a higher signal-to-noise ratio (SNR) can be obtained. The enhanced signal-to-noise ratio makes it easy to distinguish spectral peaks of interest from the noise floor, enabling early detection of emerging machine failures.

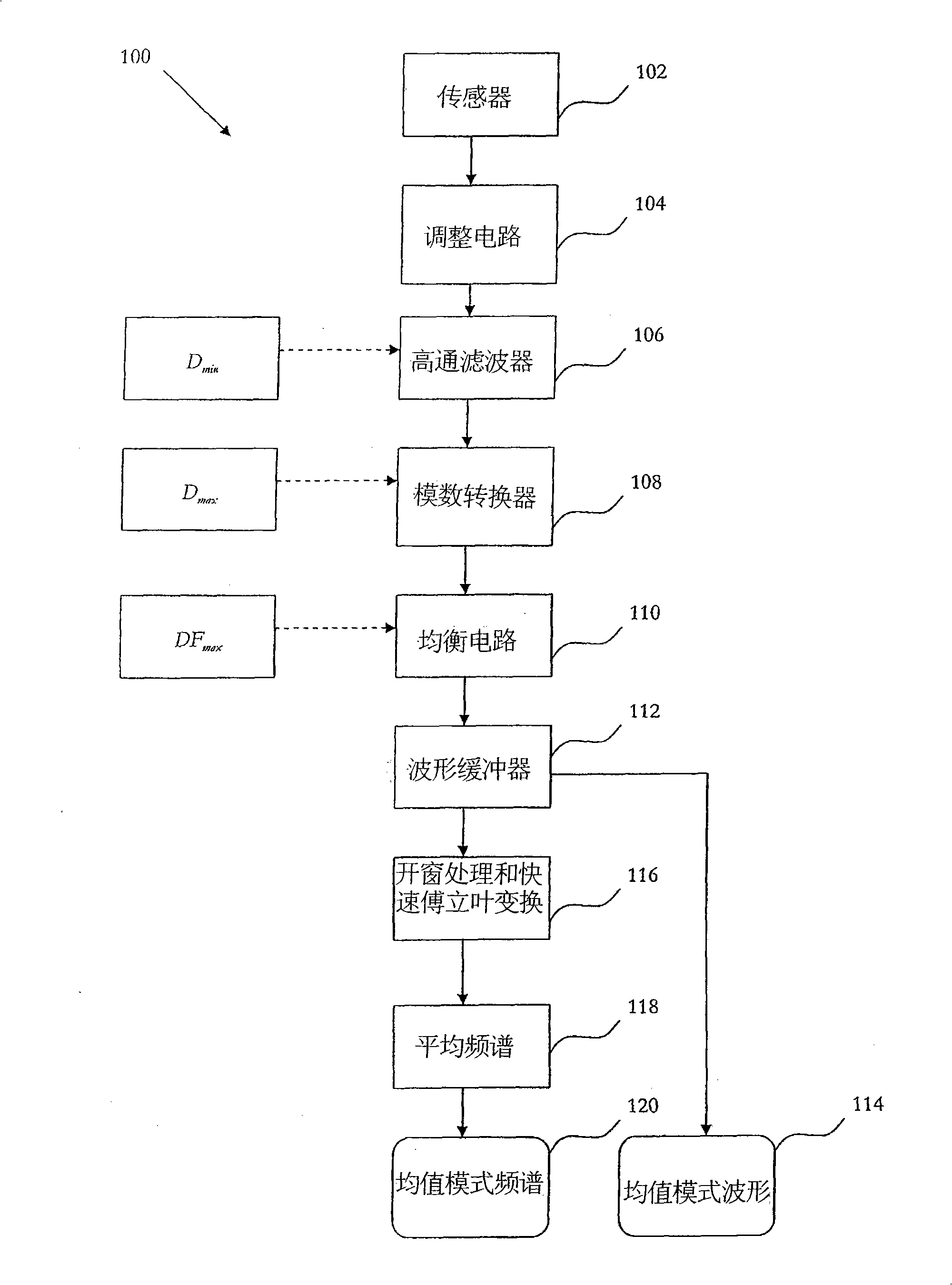

[0040] Preferred Embodiment of the System

[0041] refer to figure 1 , the simplified process flow of the preferred system is shown generally at 100 . The system 100 for vibration signal processing includes one or more vibration sensors 102 for generating electronic vibration signals representative of sensed mechanical vibrations. Sensor 102 is typically an accelerometer, but other sensors capable of sensing mechanical vibration and representing that vibration in an electronic vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com