Method for manufacturing encoder substrate

A technology of an encoder and a manufacturing method, which is applied to electrical components, electrical switches, circuits, etc., can solve the problem that the surface of the conductive pattern 8 and the surface of the insulating plastic are prone to steps, the conductive pattern 8 is difficult to achieve in small intervals, and the shape of the model is difficult to achieve. complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

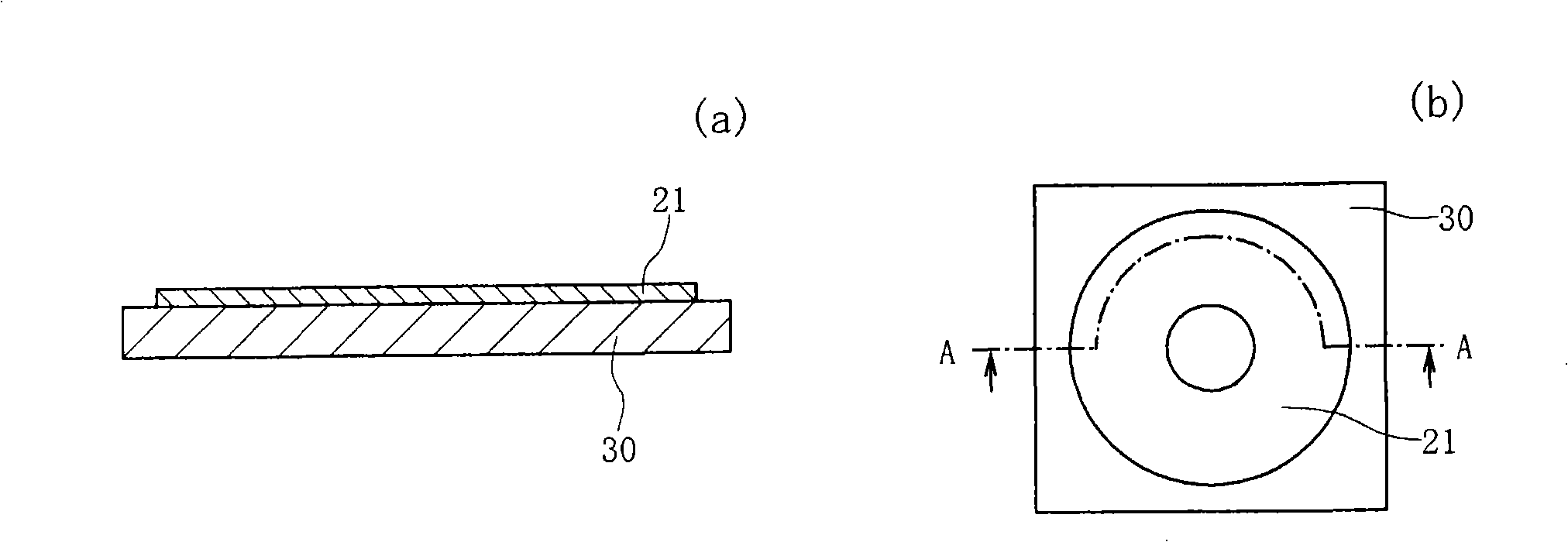

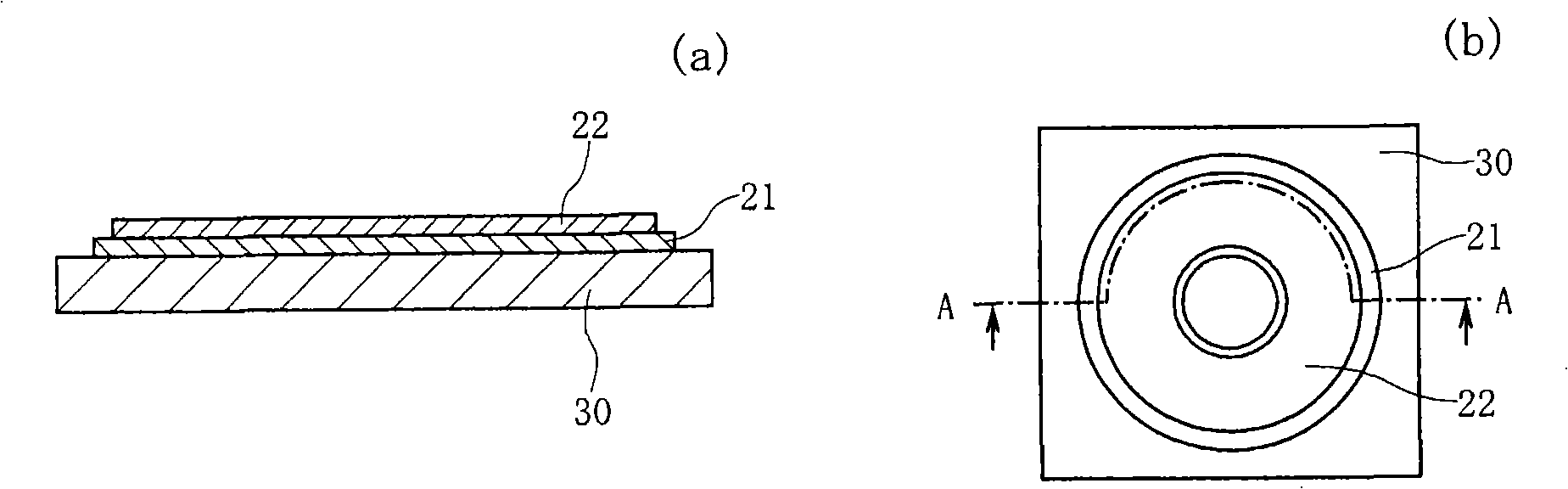

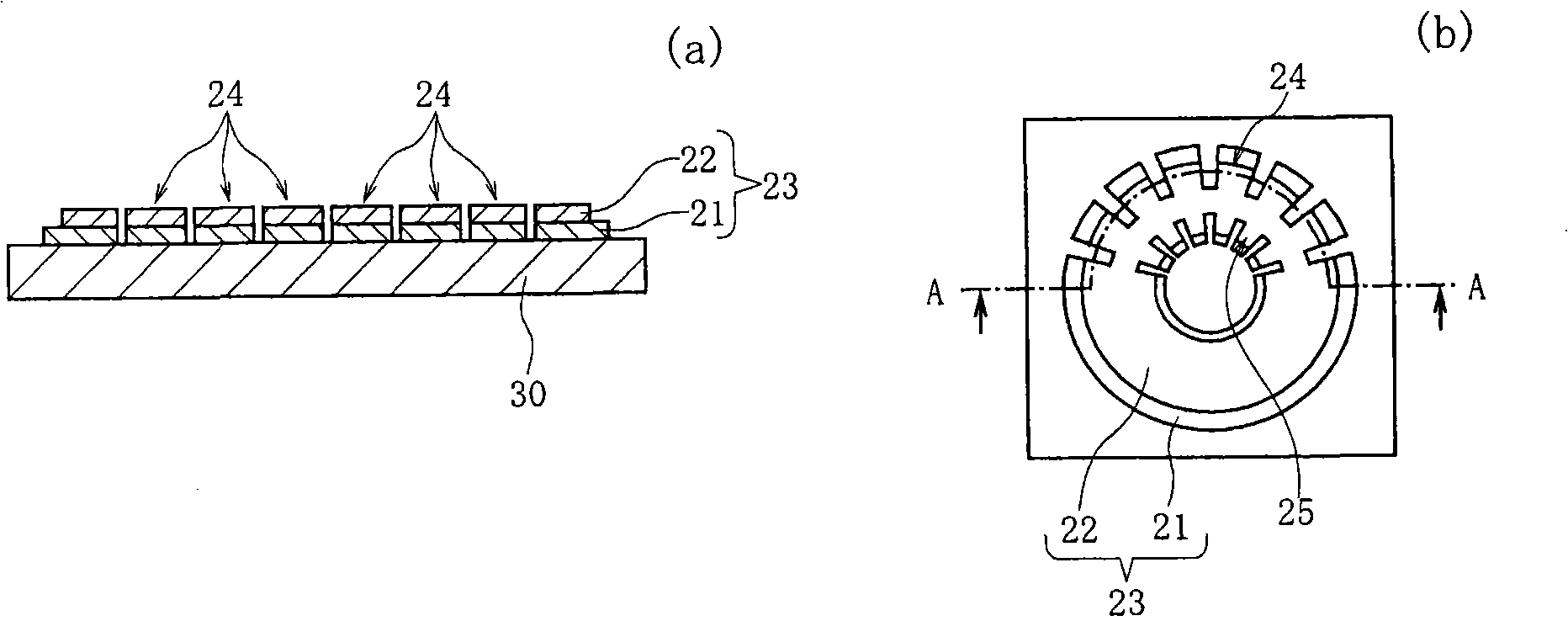

[0048] Figure 1 to Figure 6 A method of manufacturing the encoder substrate of this embodiment is shown. figure 1 (a), figure 2 (a), image 3 (a) and Figure 4 to Figure 6 It means that regardless of which process the above-mentioned encoder boards are used as figure 1 (b), figure 2 (b) and image 3 (b) The A-A line shown is cut along the film thickness direction, and the cross-sectional view seen from the direction of the arrow. figure 1 (b), figure 2 (b) and image 3 (b) is each figure 1 (a), figure 2 (a) and image 3 (a) Floor plan.

[0049] exist figure 1In the illustrated process, the first conductive layer 21 is formed by screen printing a first conductive paste on a transfer plate 30 made of, for example, a brass plate. The surface of the above-mentioned transfer plate 30 is given a mirror finish in advance. The above-mentioned transfer plate 30 is preferably made of metal. By forming the above-mentioned transfer plate 30 with metal, its thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com