Pixel structure and active element array substrate

A technology of active components and pixel structures, applied in the direction of electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of uneven etching of the gate insulating layer 50, poor characteristics of the storage capacitor C component, etc., so as to improve the display quality and avoid The effect of reducing the characteristics of the storage capacitor element and maintaining the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

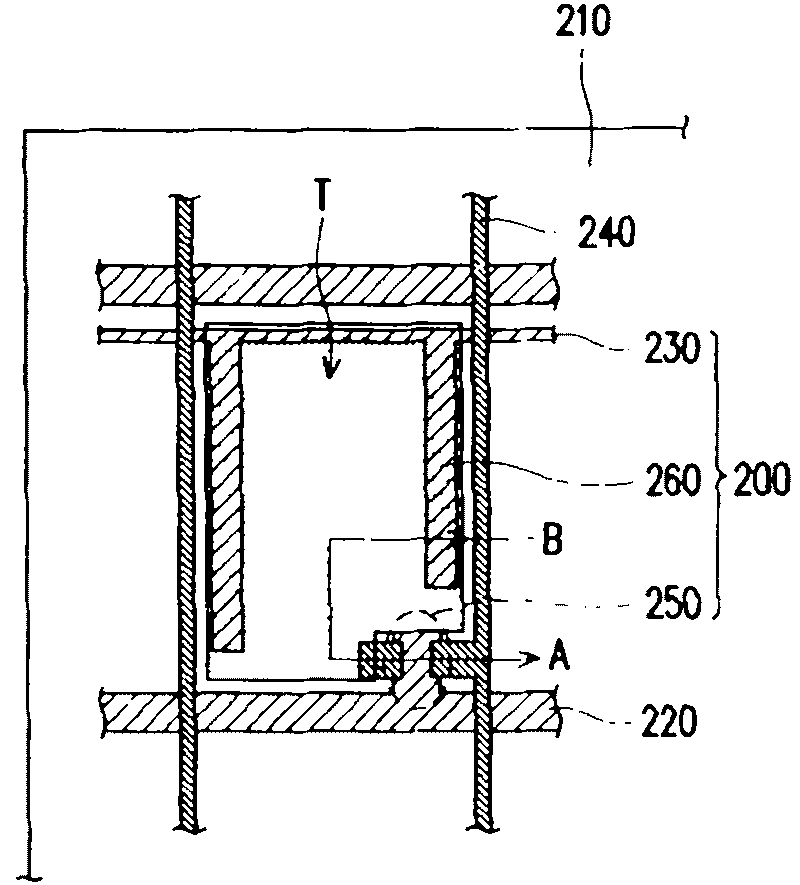

[0051] figure 2 is a schematic diagram of a pixel structure according to an embodiment of the present invention, and Figure 3A for figure 2 A schematic cross-sectional view of the pixel structure shown in , taken along the section line A-B. Please refer to figure 2 and Figure 3A , the pixel structure 200 of this embodiment is configured on a substrate 210, wherein the substrate 210 is, for example, a glass substrate, a plastic substrate or a substrate made of other materials. The pixel structure 200 is electrically connected to the scan line 220 and the data line 240, and the pixel structure 200 is mainly composed of an active element 250, a lower capacitor electrode 260, an insulating layer 270 and a pixel electrode 280. In this embodiment, the pixel structure 200 It also includes a shared wiring 230 , and the lower capacitor electrode 260 is a part of the shared wiring 230 .

[0052] Such as figure 2 and Figure 3A As shown, the active device 250 is driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com