Cutting insert

A technology of cutting inserts and inserts, applied in turning equipment, accessories of toolholders, tools for lathes, etc., can solve the problems of inability to achieve smooth chip processing, increased cutting resistance, chip blocking, etc., and achieve stable chip processing. , The effect of preventing the increase of cutting resistance and preventing chip clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

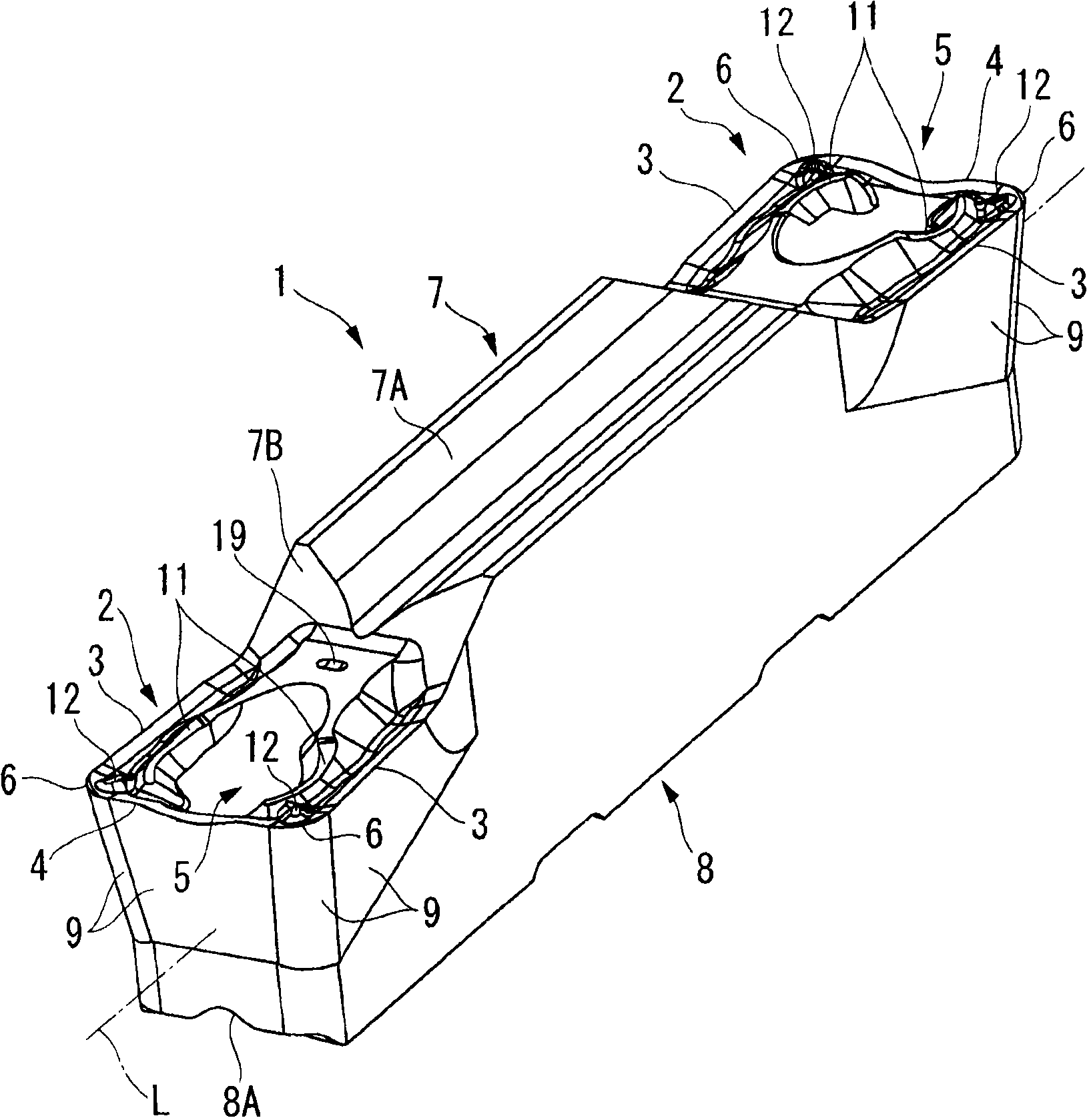

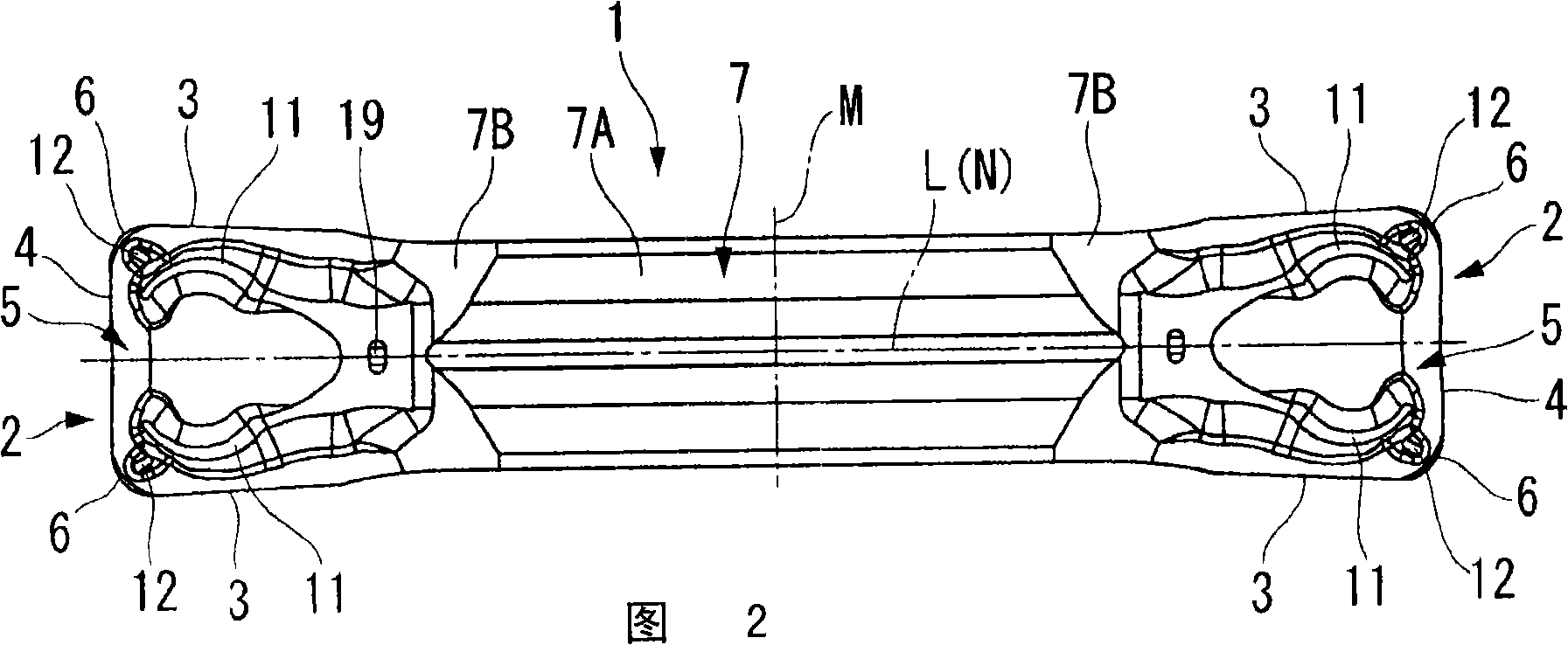

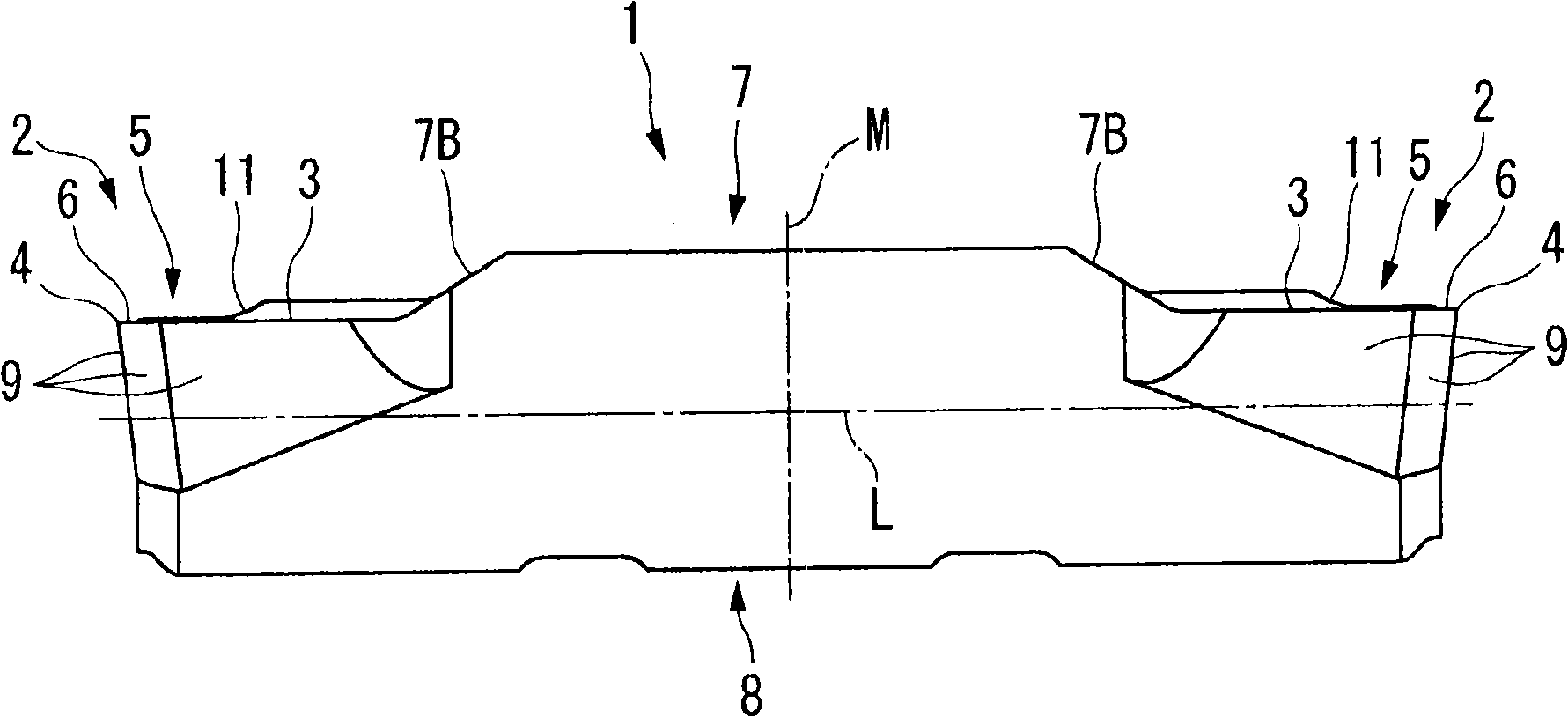

[0073] figure 1 7 to 7 are diagrams showing a first embodiment of the cutting insert of the present invention. In the present embodiment, the insert body 1 is formed of a hard material such as cemented carbide, and has a substantially square shaft shape (square column shape) extending along the axis L. As shown in FIG. The blade body 1 is formed approximately symmetrically with respect to a plane M which is perpendicular to the axis L and which is located in the length direction of the blade body 1 (direction of the axis L, FIGS. Figure 4 in the left and right directions) in the center. Furthermore, the blade main body 1 is also a symmetrical shape with respect to a plane N which is perpendicular to the plane M and which is located in the width direction of the blade main body 1 (Fig. 2 and Figure 4 in the up and down direction, in Figure 5 Middle is the left-right direction) center, including the axis L and in the thickness direction of the blade main body 1 ( image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com