Oxidized wind machinery room ventilating system and method thereof

A technology of oxidation fan and ventilation system, which is applied in mechanical equipment, machines/engines, non-variable pumps, etc., can solve the problems of reduced output of oxidation fan, influence on gypsum dehydration system, and decline in gypsum quality, so as to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

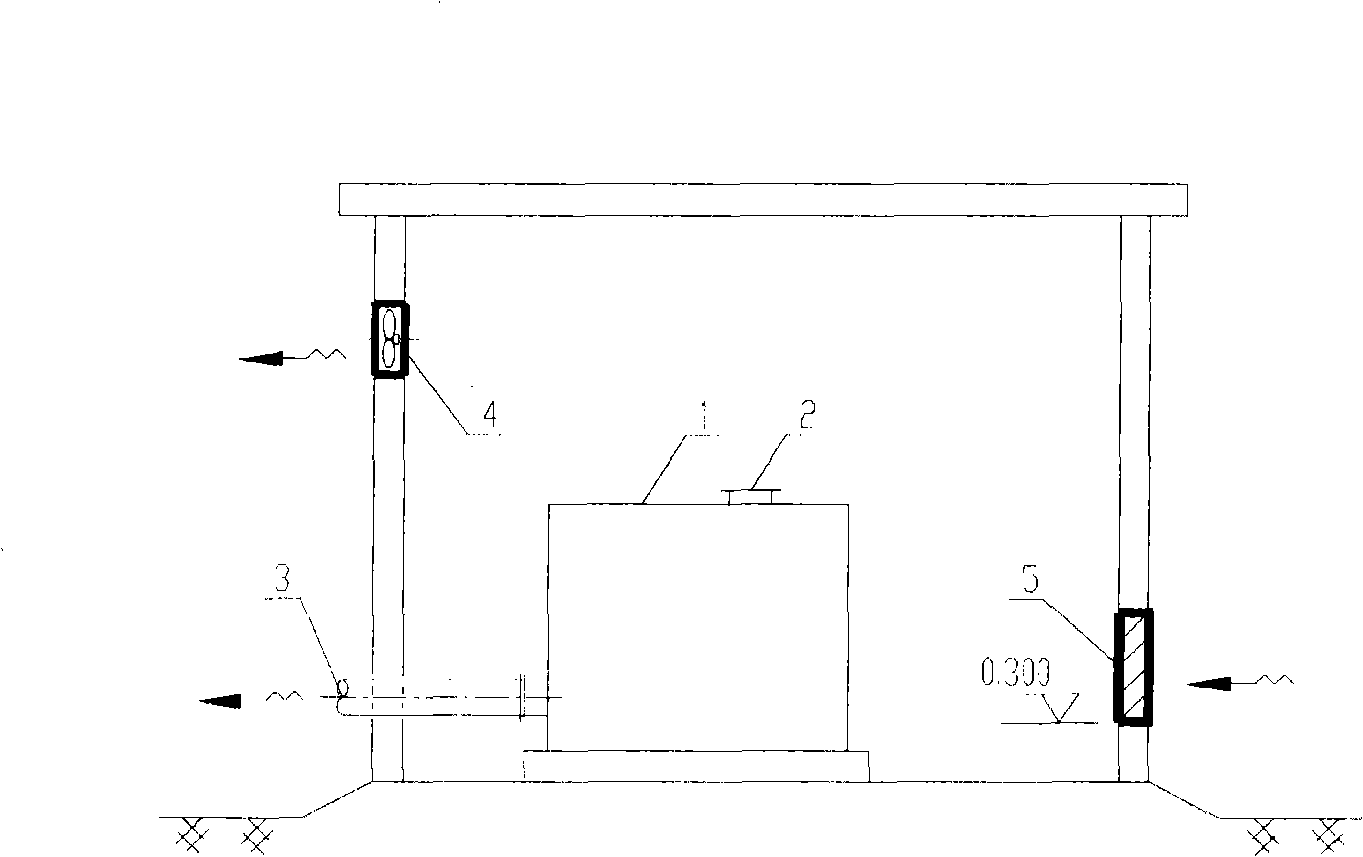

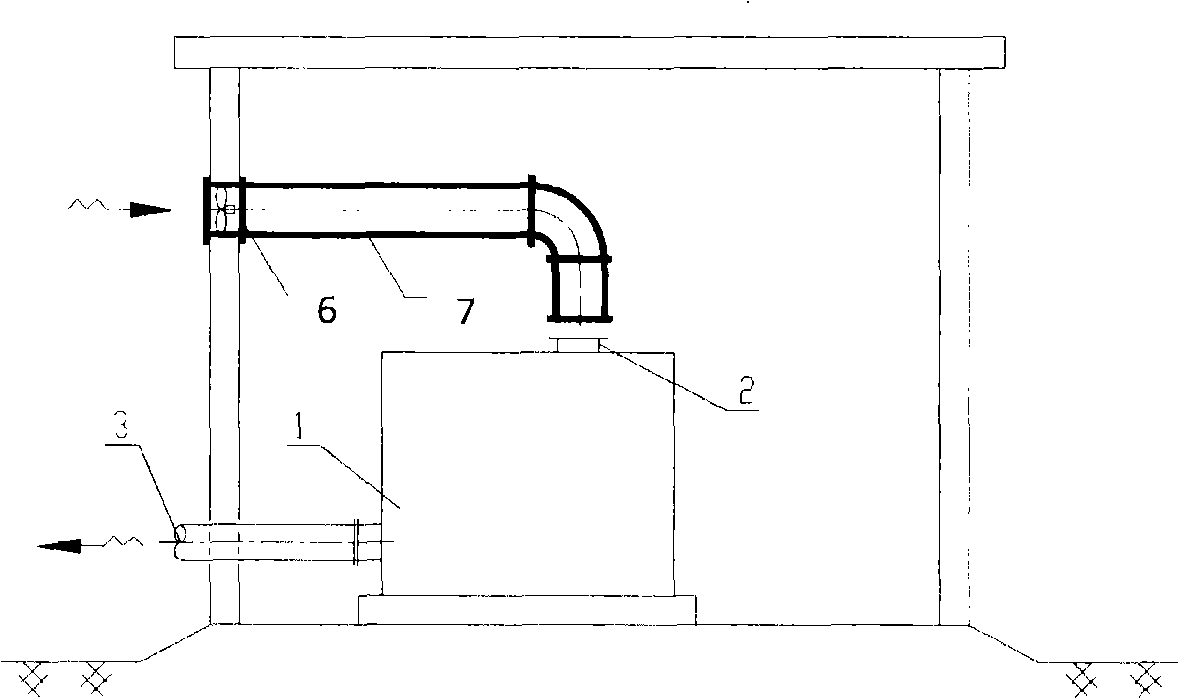

[0025] Such as figure 1 As shown, in the flue gas desulfurization island oxidation fan room of a thermal power plant in a cold region, an oxidation fan 1 is usually included, and the oxidation fan 1 includes an oxidation fan suction port 2 . Oxidation fan outlet 3 is usually arranged in the lower part of the side wall of the oxidation fan room. In the lower part of the side wall of the oxidation fan room, at a position different from the oxidation fan outlet 3, an air intake louver 5 is provided for air intake. In addition, an exhaust fan 4 for ventilation is also arranged on the side wall of the oxidation fan room for ventilation.

[0026] For example, in the flue gas desulfurization island oxidation fan room of a power plant in a cold area, it is 12 meters long, 9 meters wide, and 8 meters high. There are 2 oxidation fans, one in operation and one in standby. The air intake of the oxidation fan is 8000m 3 / h Taiwan. If you set natural air intake shutters, and the air int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com