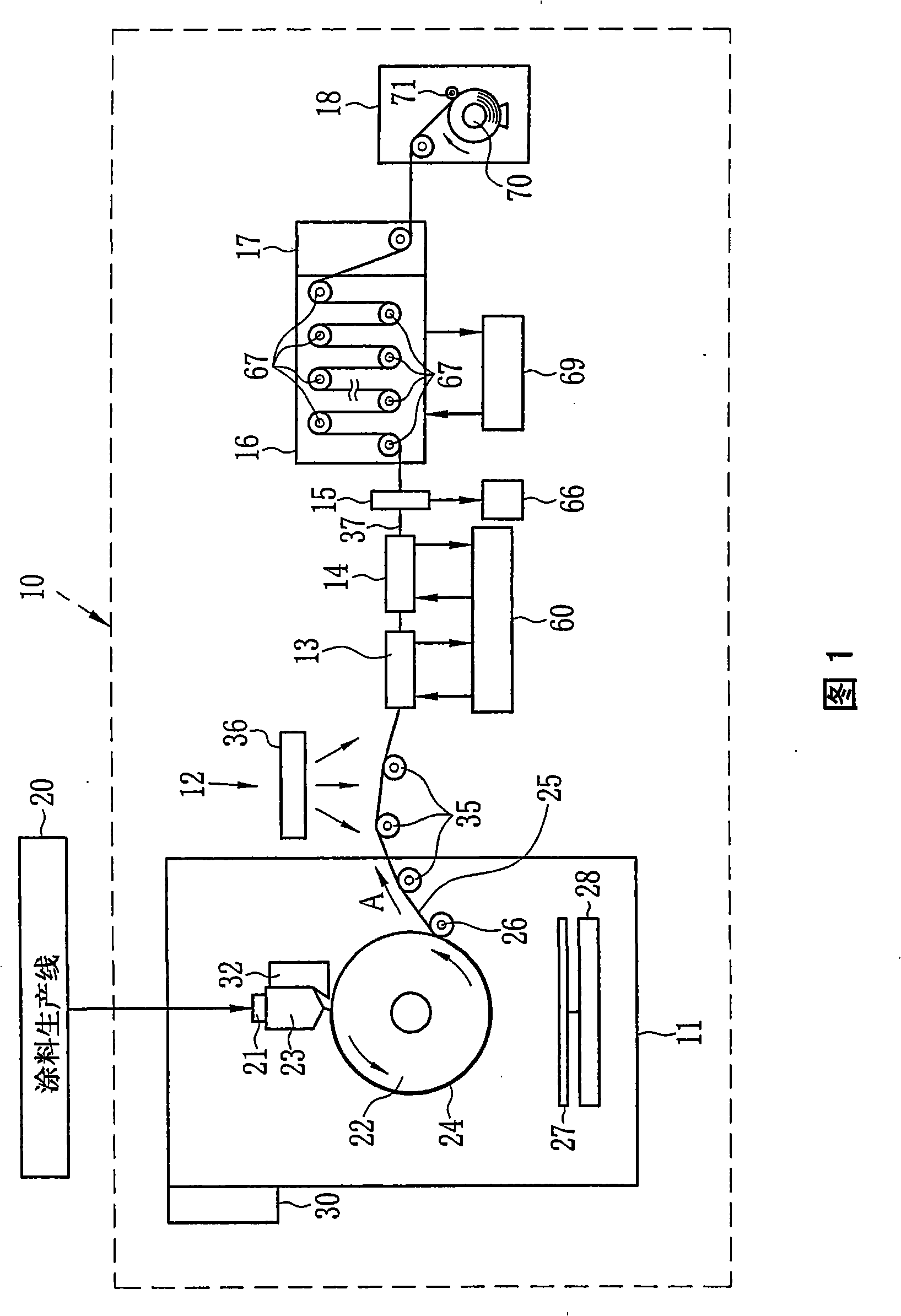

Method and apparatus for drying film and solution casting method

A drying film and drying technology, applied in lighting and heating equipment, progressive dryers, drying gas arrangement, etc., can solve problems such as weak cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

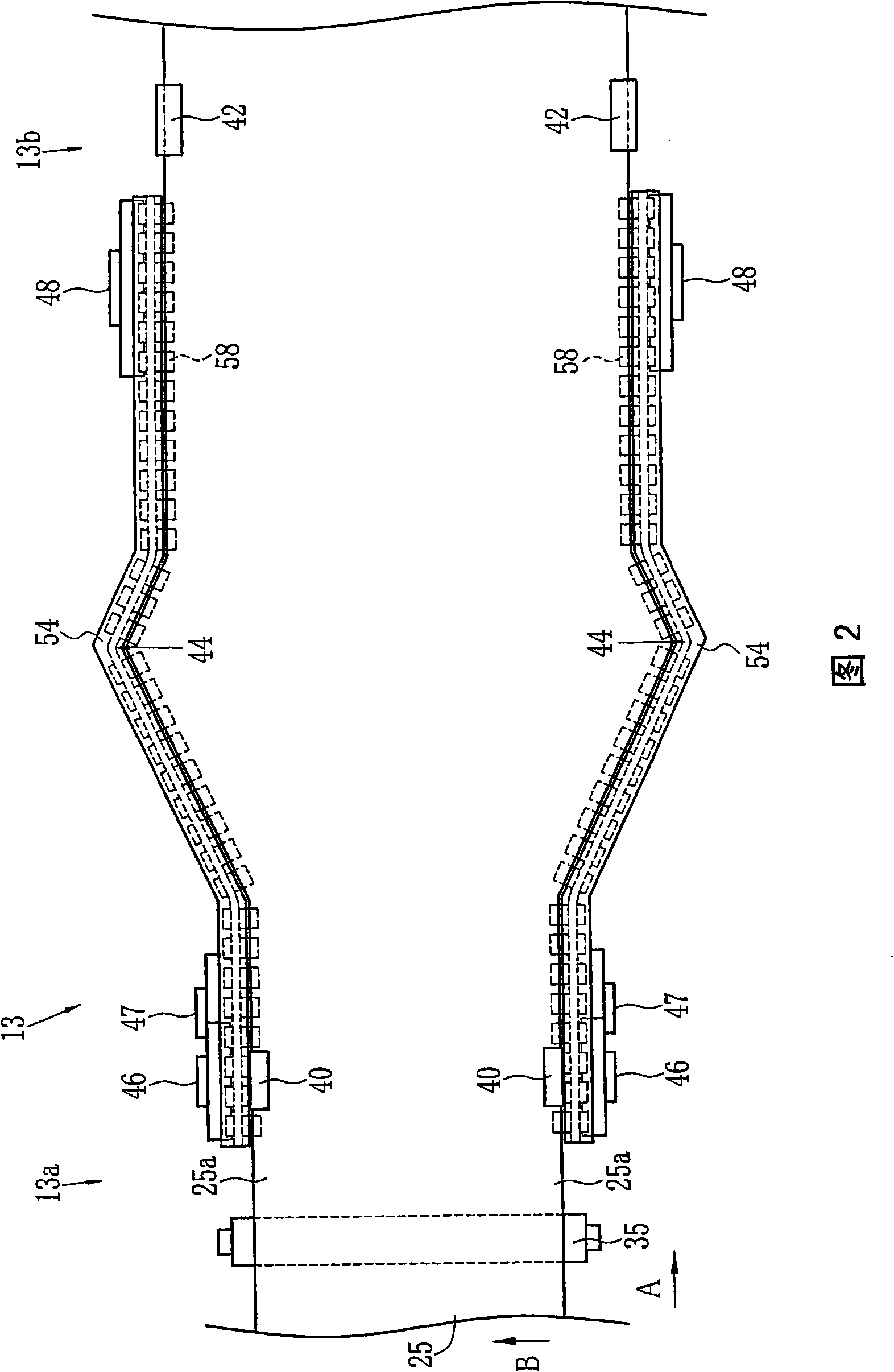

Method used

Image

Examples

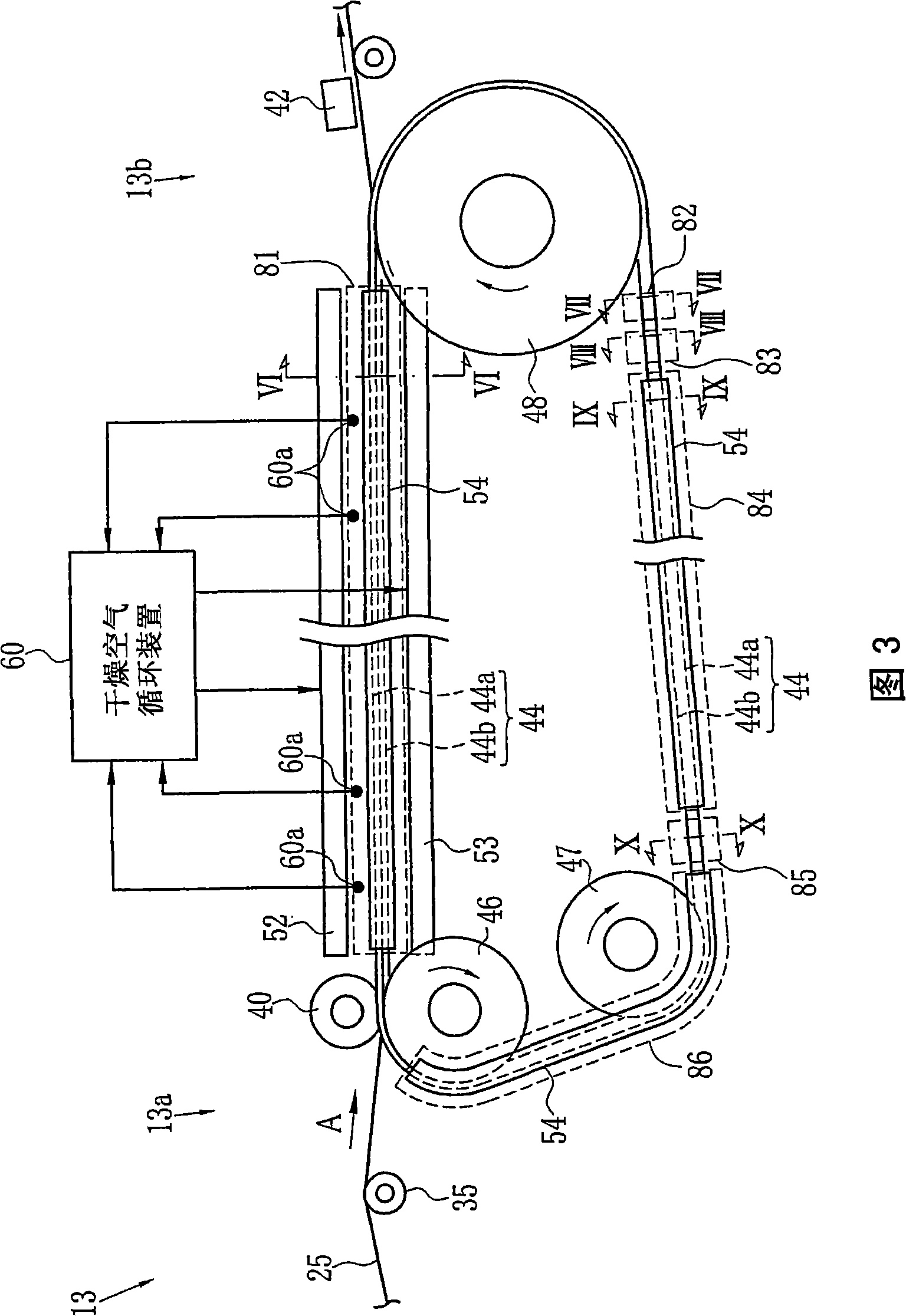

Embodiment 1

[0141] In the air-jet cleaning zone 83, nitrogen gas is blown onto the pins 72, the needle plate 73, the carrier body 74, the rails 44a and 44b, and the guide rollers 76 to 79 (hereinafter referred to as air-jet cleaning).

Embodiment 2

[0143] In addition to air jet cleaning, steam is blown onto the pins 72, the needle plate 73, the rails 44a and 44b, the carrier body 74, and the guide rollers 76 to 79 through the nozzles 120a to 120c in the steam cleaning zone 82 (hereinafter referred to as steam cleaning) .

Embodiment 3

[0145] In addition to jet cleaning and steam cleaning, nitrogen gas is purged from the track covers 54 and 55 (hereinafter referred to as gas purging).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com