Device for suspending a unit such that vibrations are damped and complete equipment

一种成套设备、套环的技术,应用在机械设备、非旋转振动抑制、薄板连接等方向,能够解决少有自由空间、困难延长、增加成套设备安装过程等问题,达到缩短安装过程、简化安装过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

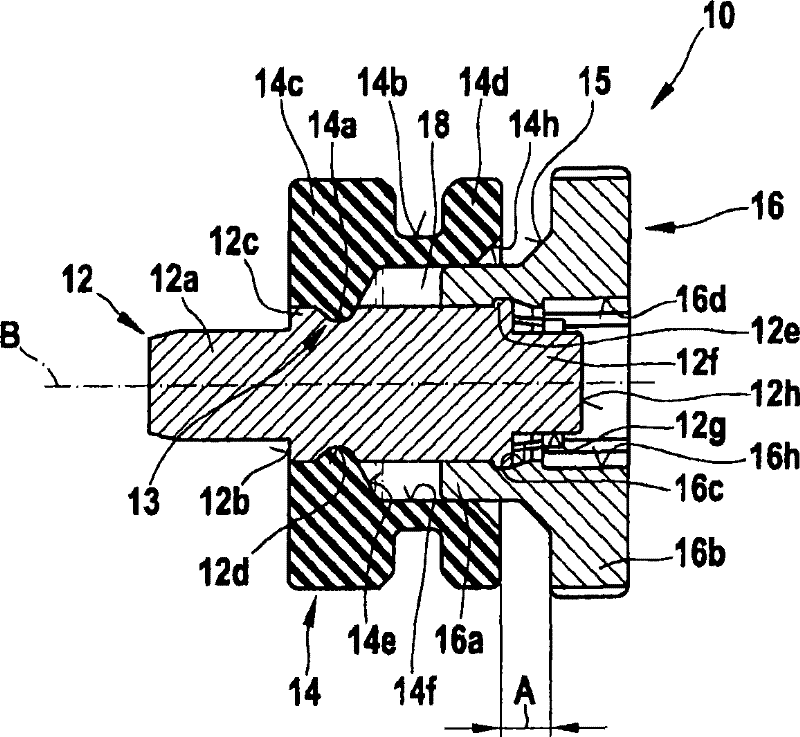

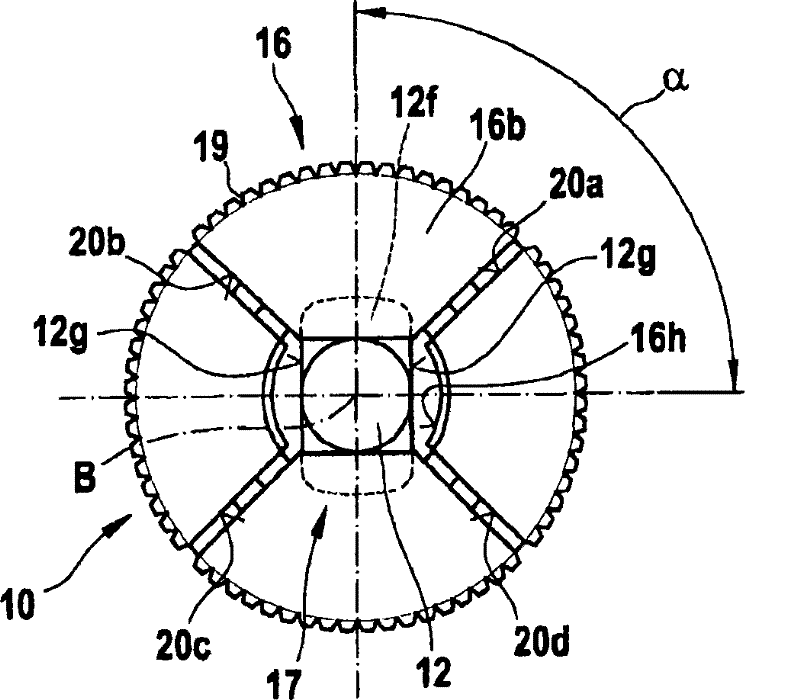

[0011] exist figure 1 The device 10 shown in is constituted by a pull rod 12 , an elastomer piece 14 supported by the pull rod, and a clamp 16 partially projecting into the interior of the elastomer piece 14 . The gripper 16 is guided on the draw rod 12 in an axially displaceable manner and can be transferred from the basic position to the clamping position by manual operation.

[0012] The tie rod 12 is a cylindrical metal piece, preferably made of solid material, with a multiple stepped profile. exist figure 1 The longitudinal axis of the tie rod 12 and the longitudinal axis of the entire device 10 are denoted by B. The first tie rod section 12a with a reduced outer diameter serves to secure the tie rod at the figure 1 in the accommodating hole of the kit not shown. This first section 12a can have a smooth or knurled surface on the circumferential side when it is provided that the tie rod is anchored in the receiving hole by means of a press-in method. If it is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com