Word-carving machine for flange

A type of letter rolling machine and flange technology, applied in printing, stamping and other directions, can solve the problems of poor quality and low degree of mechanization of lettering on the surface of the flange, and achieve the effect of uniform depth, clear writing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

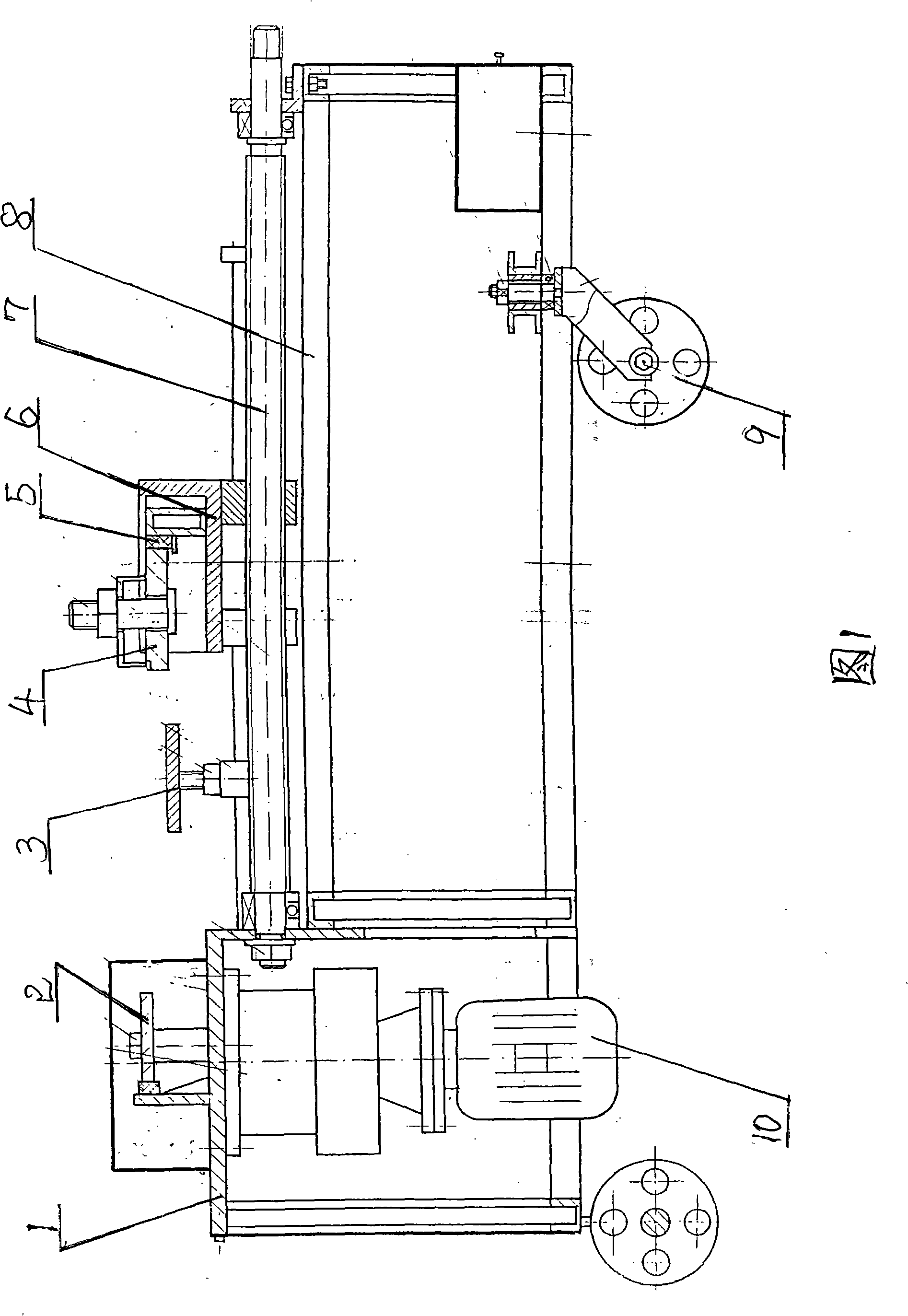

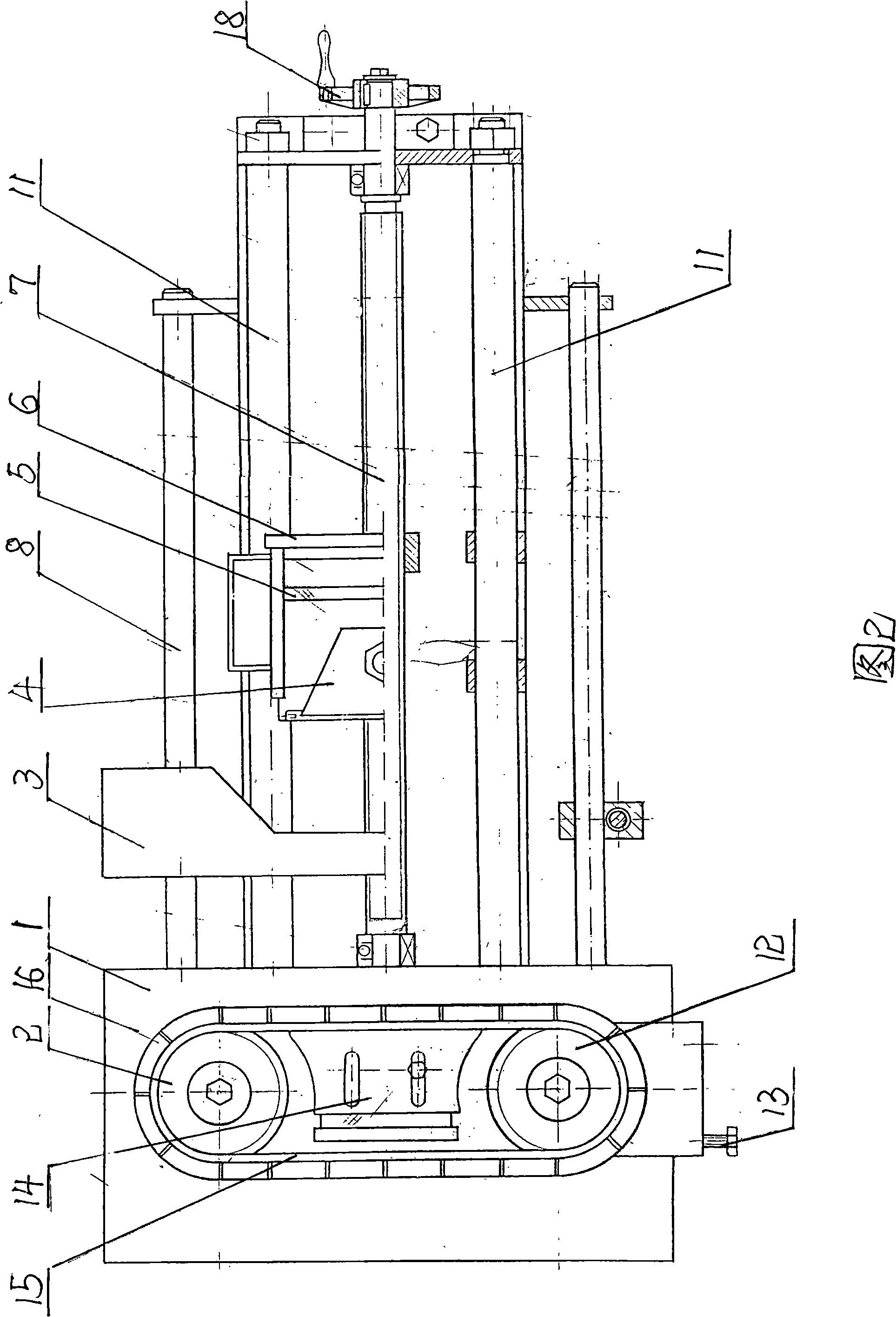

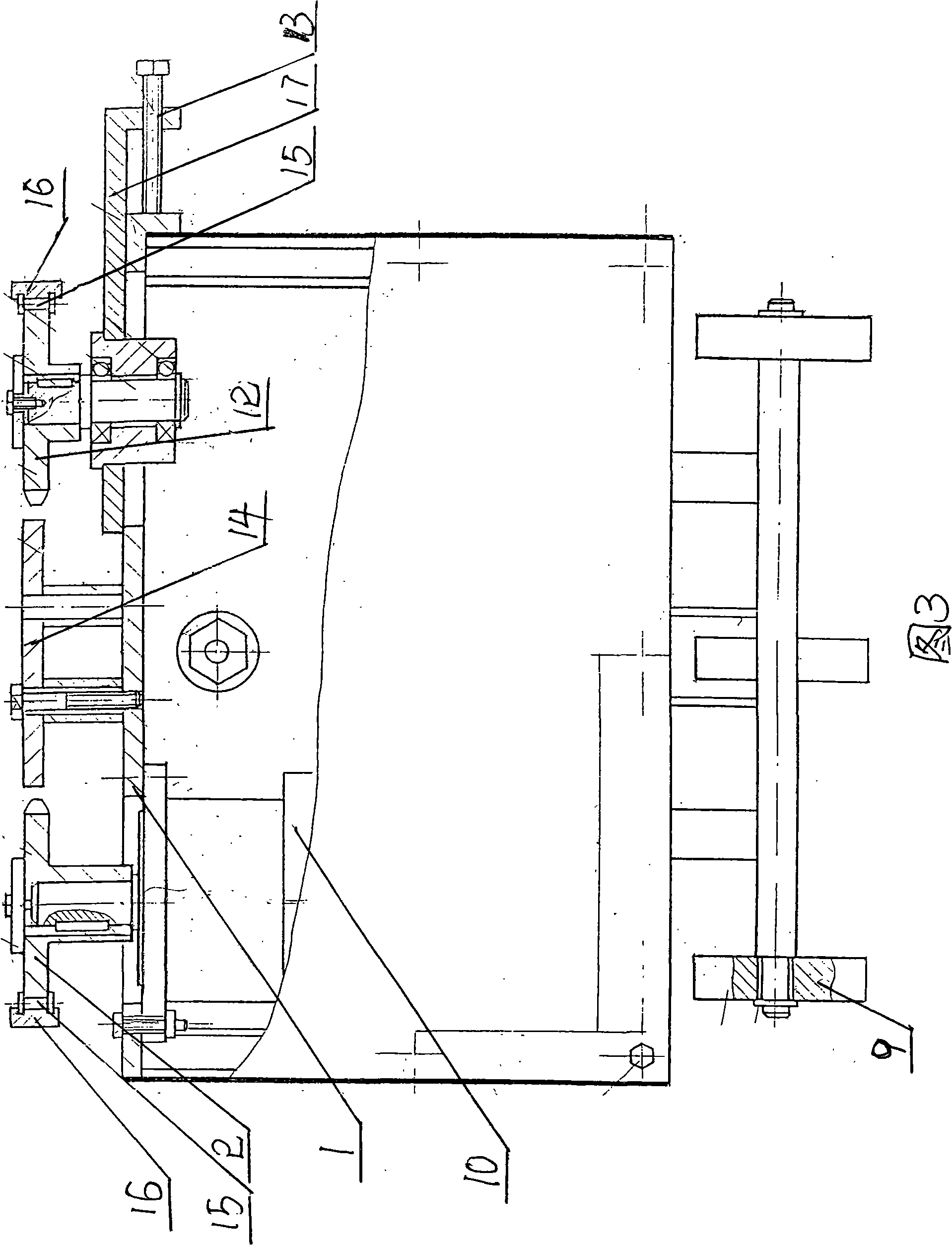

[0011] As shown in Fig. 1 schematically, a kind of flange rolling machine comprises machine frame 8, is provided with guide frame on machine frame 8, and the both sides of guide frame are guide rails 11, and the middle part of guide frame is drive screw 7, on guide frame A propulsion frame 6 is provided on the top, the guide rail 11 and the drive screw 7 pass through the propulsion frame 6, the drive screw 7 and the propulsion frame 6 are threadedly socketed, one end of the machine frame 8 is provided with a character rolling device, and the character rolling device includes a Motor 10, platform 1 is provided with two sprockets 2,12 that are connected by chain 15, and chain 15 is fixed with some chain blocks 16 that have font, and wherein a sprocket 2 is connected with motor 10, and sprocket 2,12 A top plate 14 is provided between them, and a bracket 3 is also provided between the propelling frame 6 and the chain 15 .

[0012] The side corresponding to the chain 15 on the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com