Correction executing mechanism

An actuator and roller technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of increasing the extra tension of the substrate, large color changes, and tensile deformation of the substrate, and reduce the deviation correction cycle. To friction, to ensure the quality of the substrate, to avoid the effect of tensile deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

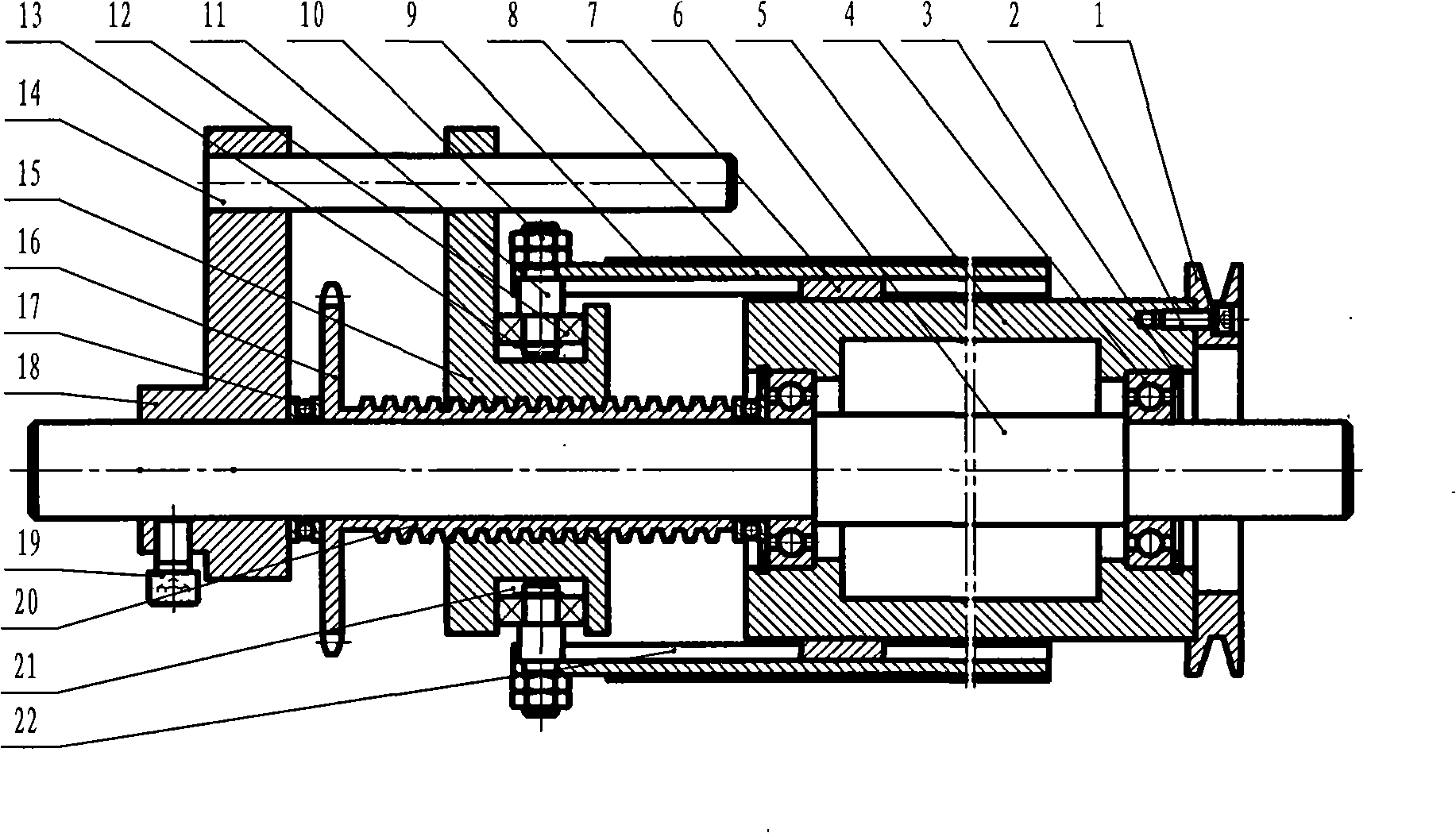

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0010] In this embodiment, the deflection correction of a plastic film as a base material is taken as an example.

[0011] The present invention comprises fixed shaft 6, cylinder 5, spoke 8, leading screw 20, leading screw nut 15, guide rod 14 and guide rod mounting seat 18; The outer side is provided with a retaining ring 3, and the outer end of the cylinder 5 is provided with a pulley 1 with a screw 2, and eight fixed sliders 7 are evenly arranged on the outer surface of the cylinder 5 along its circumference; the upper end of each T-shaped slider 7 They are all placed in the chute 22 at the bottom of the corresponding spoke 8; the upper surface of the spoke 8 is provided with a friction layer 9 of plastic material compatible with the plastic film substrate. The fixed shaft 6 at the other end of the drum 5 is sleeved with a lead screw 20 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com