Fatigue test sample of alloy coating pumping rod / polish rod and preparation thereof

A technology of alloy coating and fatigue test, which is applied in the preparation of test samples, measuring devices, instruments, etc., to achieve the effect of shortening production cycle, saving costs and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 sample

[0027] 1. Take a long original base material, which is 20CrMo sucker rod / polished rod base material with a diameter of 28.6mm, determine the number and length of fatigue samples according to the fatigue test requirements, and mark and divide the original base material , define the uncoated substrate area and the alloy coated substrate area, and ensure that the lengths of the two uncoated substrates at both ends are 100mm to 200mm, and the length of the alloy coated substrate in the center is 200mm to 400mm;

[0028] 2. Spray welding the nickel-based self-fluxing alloy coating on the alloy coating substrate area determined in the previous step by spray welding process to prepare the corresponding alloy coating;

[0029] 3. Cut according to the label before preparing the alloy coating, and then obtain multiple required fatigue test samples.

Embodiment 2

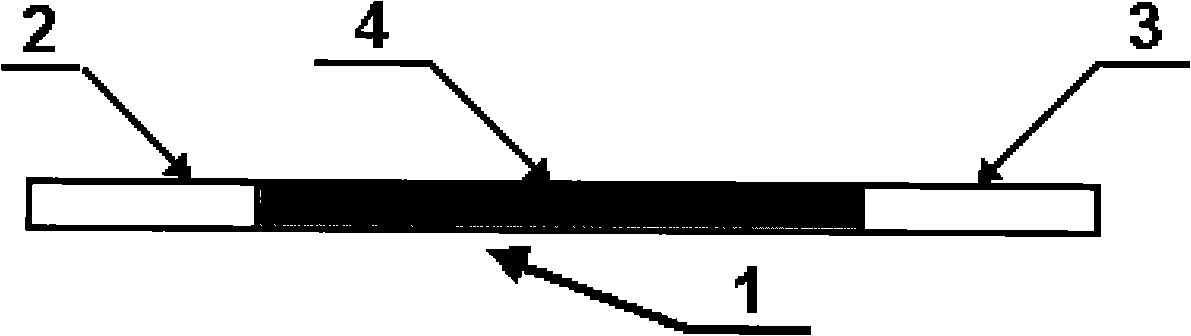

[0031] According to the steps described in Example 1, the alloy coated sucker rod / polished rod fatigue test sample of the present invention has been prepared by adopting 20CrMo sucker rod / polished rod base material and nickel-based self-fluxing alloy of 28.6mm diameter specification, such as figure 1 As shown, the test sample is a short rod 1 with a total length of 400mm. The short rod is composed of two sections of uncoated substrates 2, 3 and one section of alloy coated substrate 4. The two sections without The coating substrate is evenly distributed on both ends of the short rod, each with a length of 100mm; the alloy coating substrate is located in the center of the short rod, and the length is 200mm.

Embodiment 3

[0033] According to the steps described in Example 1, the alloy coated sucker rod / polished rod fatigue test sample of the present invention has been prepared by adopting 20CrMo sucker rod / polished rod base material and nickel-based self-fluxing alloy of 28.6mm diameter specification, such as figure 1 As shown, the test sample is a section of short rod 1 with a total length of 500 mm. The short rod is composed of two sections of uncoated substrates 2, 3 and one section of alloy coated substrate 4. The two sections without The coating base material is evenly distributed on both ends of the short rod, each with a length of 100 mm; the alloy coating base material is located in the center of the short rod, and the length is 300 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com