Fiber monofilament high-temperature tensile property testing method and device

A technology of tensile properties and testing devices, applied in the direction of measuring devices, auxiliary controllers with auxiliary heating devices, using stable tension/compression to test material strength, etc., can solve the incompletely real response fiber tensile properties , It is not easy to test single-filament samples at high temperature online, and there are no problems such as fiber monofilaments, so as to ensure heating efficiency and temperature uniformity, improve test success rate, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

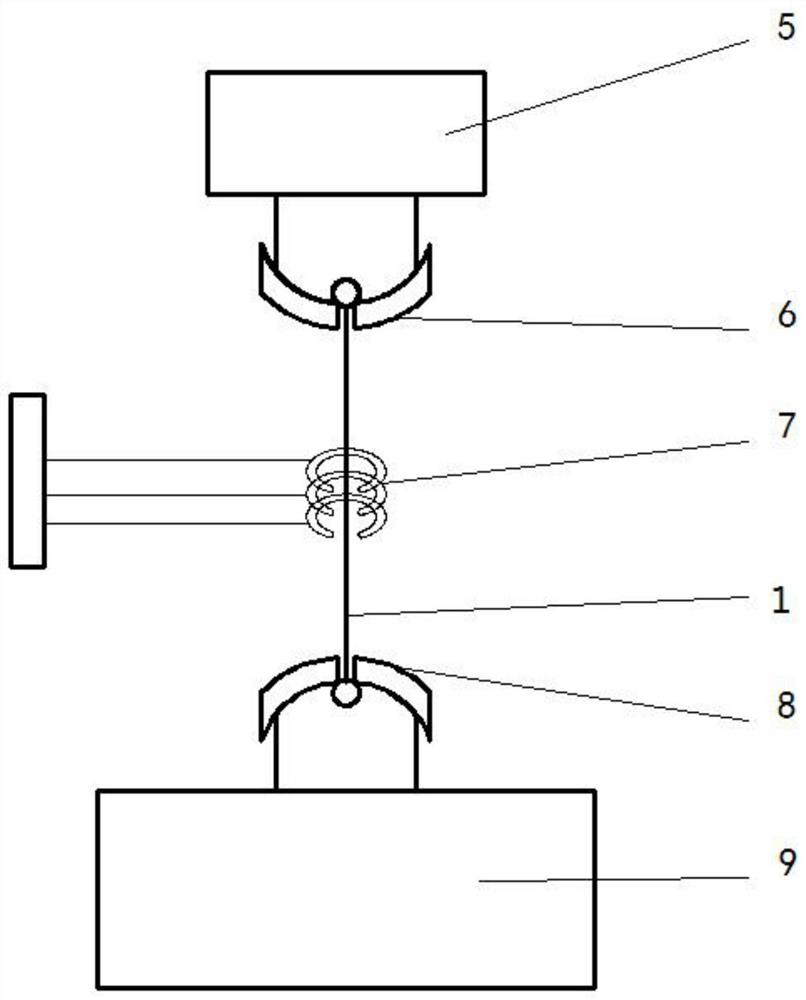

[0068] Such as image 3 As shown, the present embodiment provides a fiber monofilament high-temperature tensile performance testing device, including a tensile testing machine testing device, a high-temperature heating device 7 and a test and data processing system; wherein, the tensile testing machine testing device includes a sensor 5 and a sample mounting device; the sample mounting device includes an upper mounting end 6 and a lower mounting end 8; the mounting surfaces of the upper mounting end 6 and the lower mounting end 8 are symmetrical arcs. The tensile testing machine test device is placed on the base 9.

[0069] Specifically, the high-temperature heating device 7 adopts a C-shaped heating element coil group, and the coil group includes three sections, namely an upper section, a middle section, and a lower section, and each section is a C-shaped heating element coil; each section can be heated separately.

[0070] Specifically, the high-temperature heating device 7...

Embodiment 2

[0074] This embodiment provides a method for testing the high-temperature tensile properties of fiber monofilaments, including:

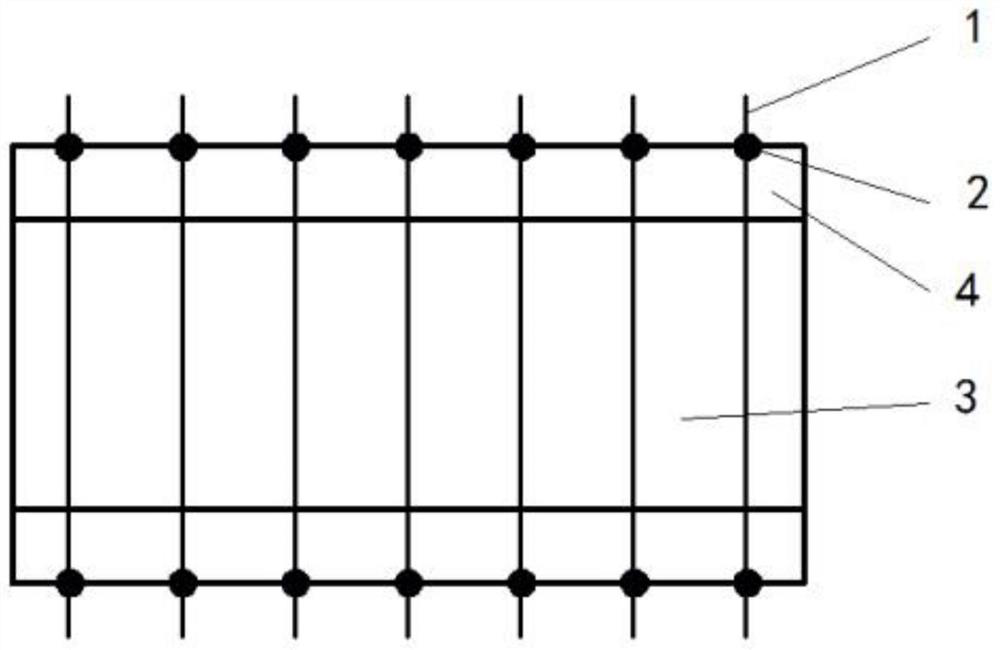

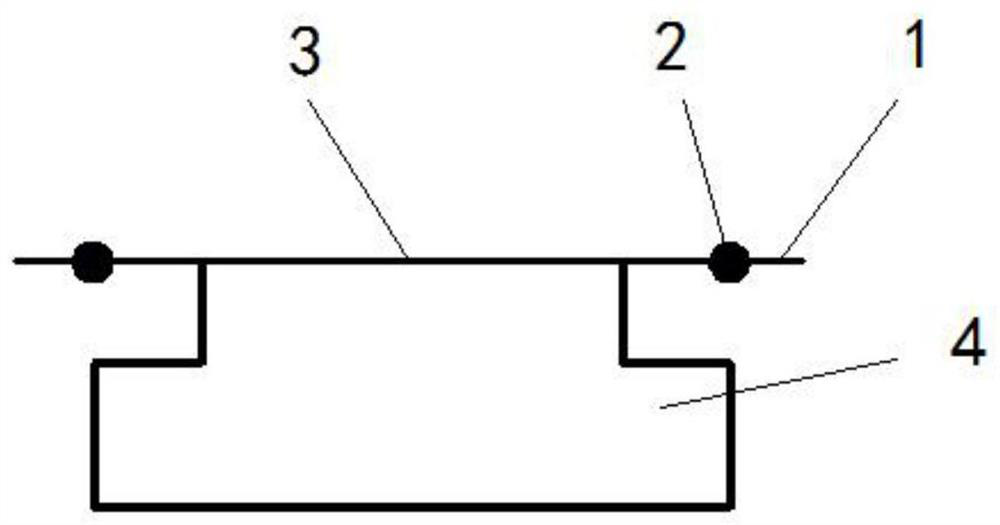

[0075] Step 1: Pick multiple fiber monofilaments from the fiber filaments to be tested, and place the multiple fiber monofilaments neatly across the sample preparation table in order to ensure that the two ends of the fiber monofilaments are naturally aligned in the width direction of the sample preparation table. stick out;

[0076] Step 2: Use an adhesive to drop a drop at both ends of the fiber monofilament that naturally protrudes from the sample preparation table, and wait for the adhesive at both ends of the fiber monofilament to form spherical beads and naturally solidify;

[0077] Step 3: Turn on the tensile testing machine and set the test program for use, hang the prepared fiber monofilament to the upper mounting end 6 and the lower mounting end 8 of the tensile testing machine testing device, and heat at high temperature The device is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com