Indexible circular milling insert and milling tool

A milling insert, circular technology, applied in the field of indexable circular milling inserts and milling tools, can solve problems such as unreasonable, cutting edge area damage, affecting tool life, etc., to improve cutting performance and prolong service life. Longevity, good chip breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

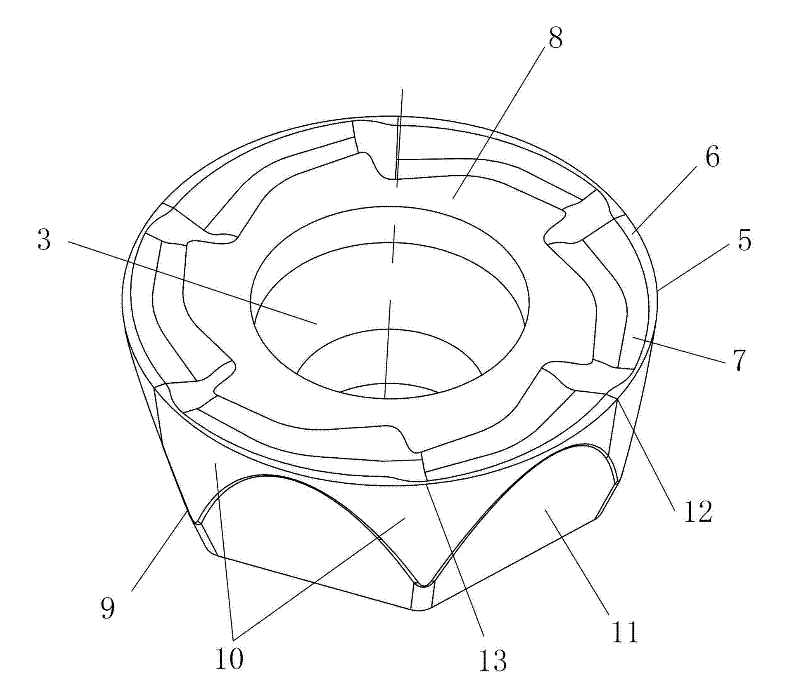

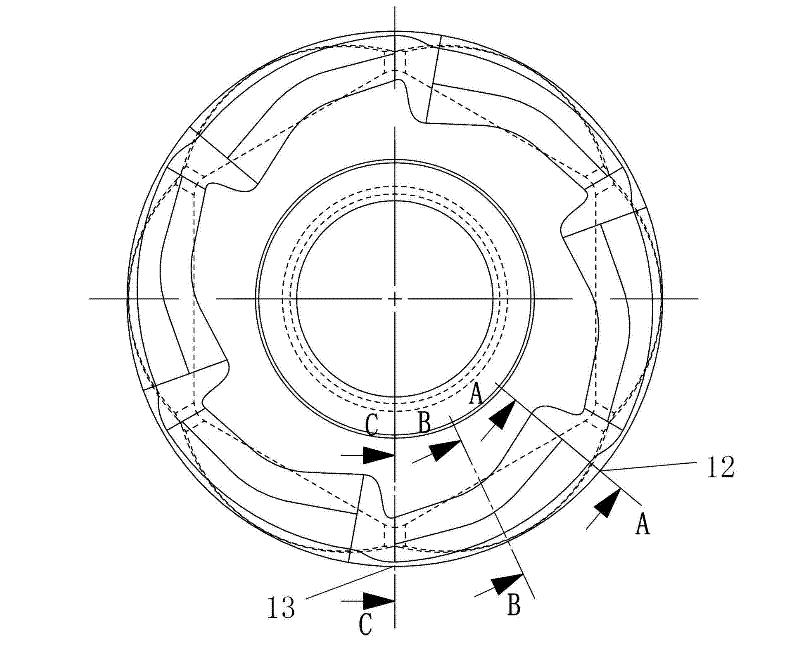

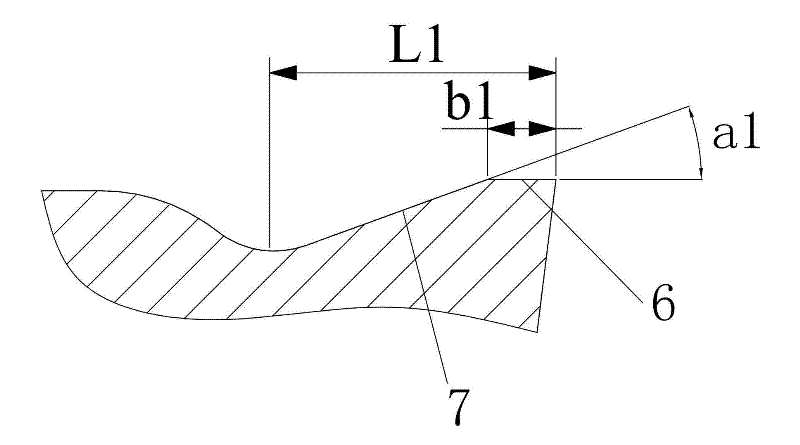

[0021] Figure 1 to Figure 6 An embodiment of an indexable circular milling insert of the present invention is shown. The milling insert includes an upper surface 8, a lower surface 9, and a flank surface 10 located between the upper surface 8 and the lower surface 9. The upper surface 8 is provided with a cutting edge band surface 6 and a chip guide surface 7, and a plurality of positioning side surfaces 11 are provided on the flank surface 10, and the cutting edge band surface 6 and the flank surface 10 intersect to form a plurality of cutting edges 5 that can be used alternately, The maximum actual cutting thickness on the cutting edge 5 is the cutting edge front end 12, and the minimum actual cutting thickness on the cutting edge 5 is the bottom end 13 of the cutting edge. At each cutting edge 5, the bottom end 13 of the cutting edge faces the cutting edge. The direction of the front end portion 12, that is, according to the changing trend of the actual cutting thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com