Engine generator

An engine and generator technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of large axial size of engine generators, inconvenient assembly, complex structure, etc., and achieve compact structure, simplified structure, and convenient assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

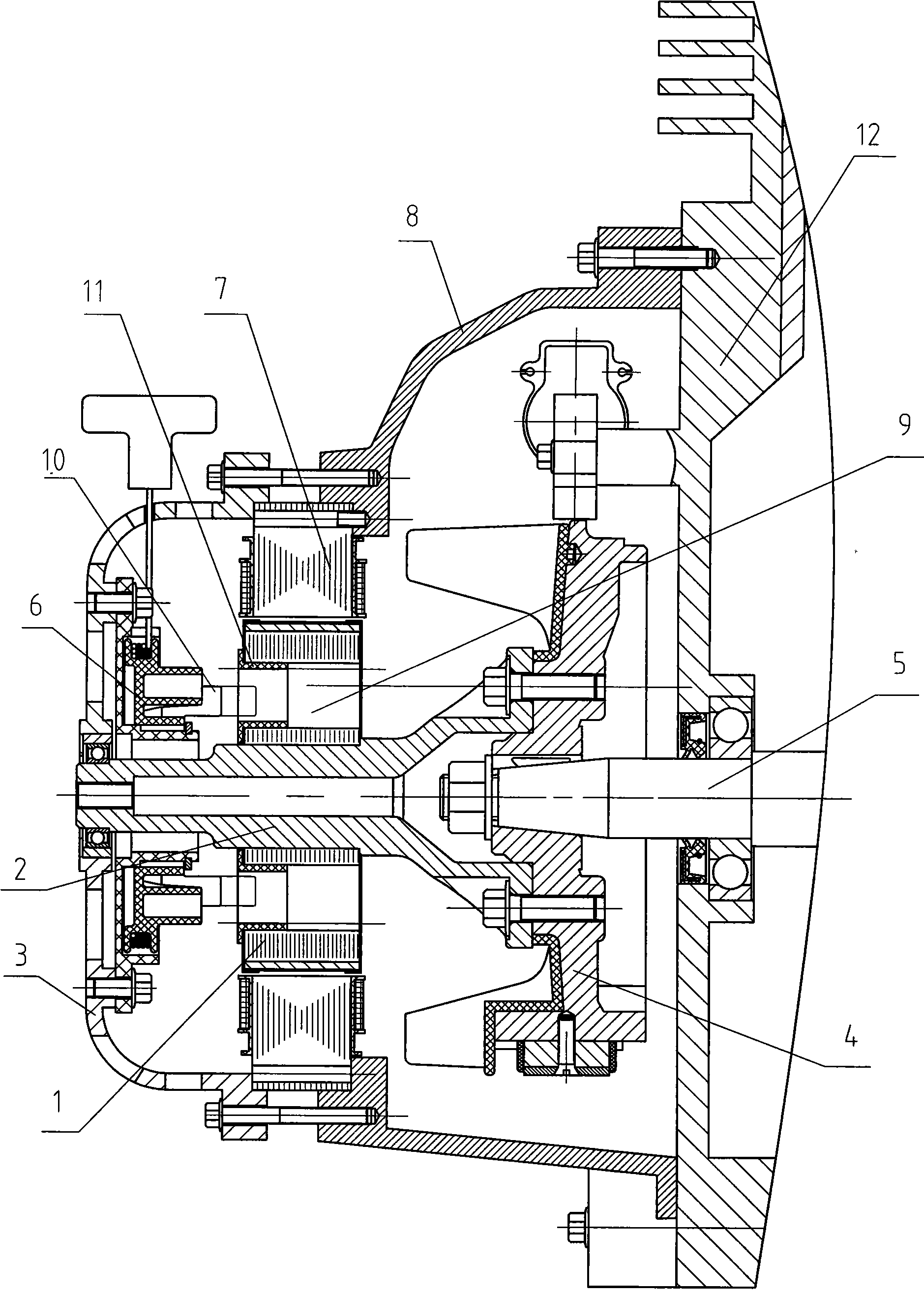

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

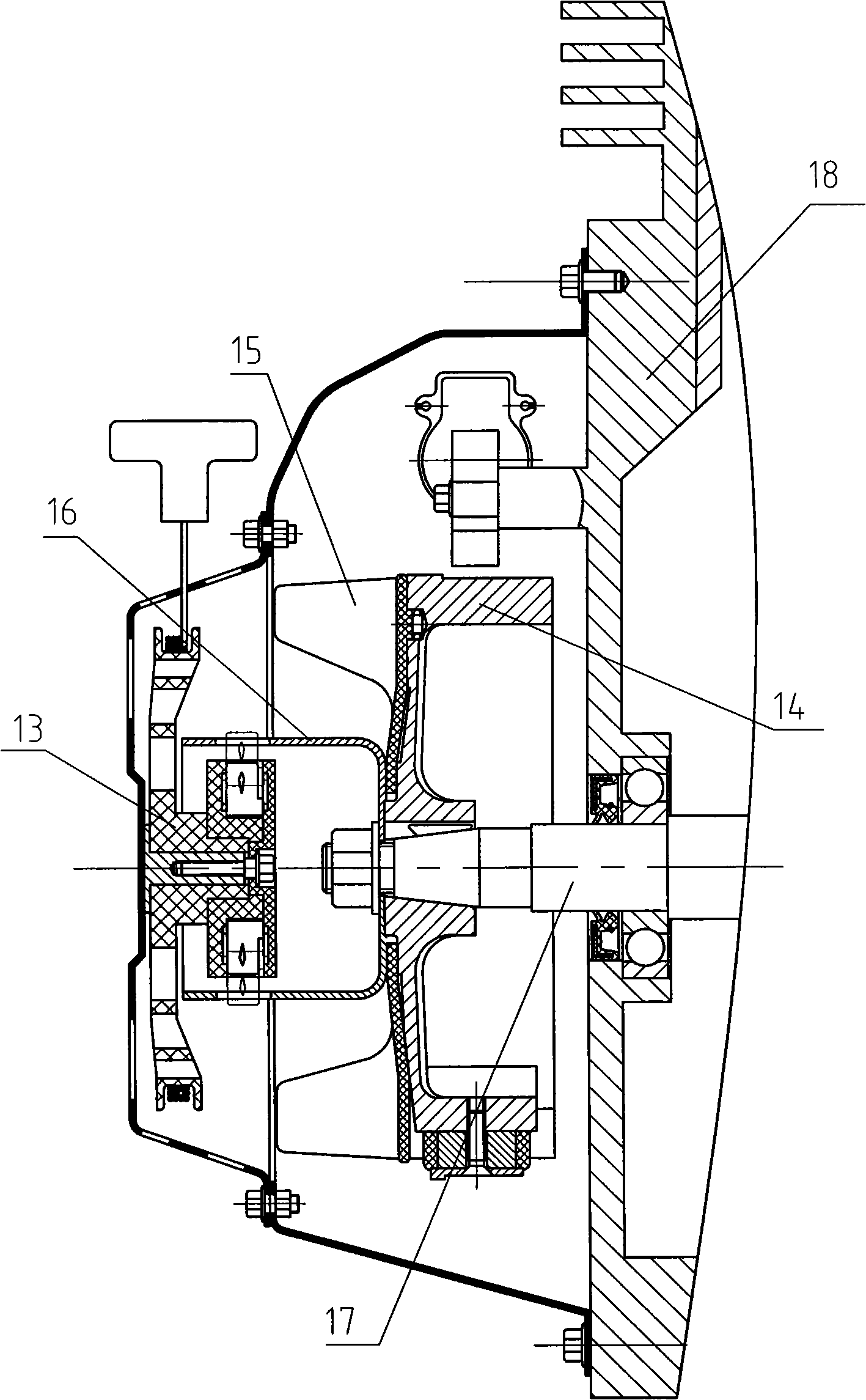

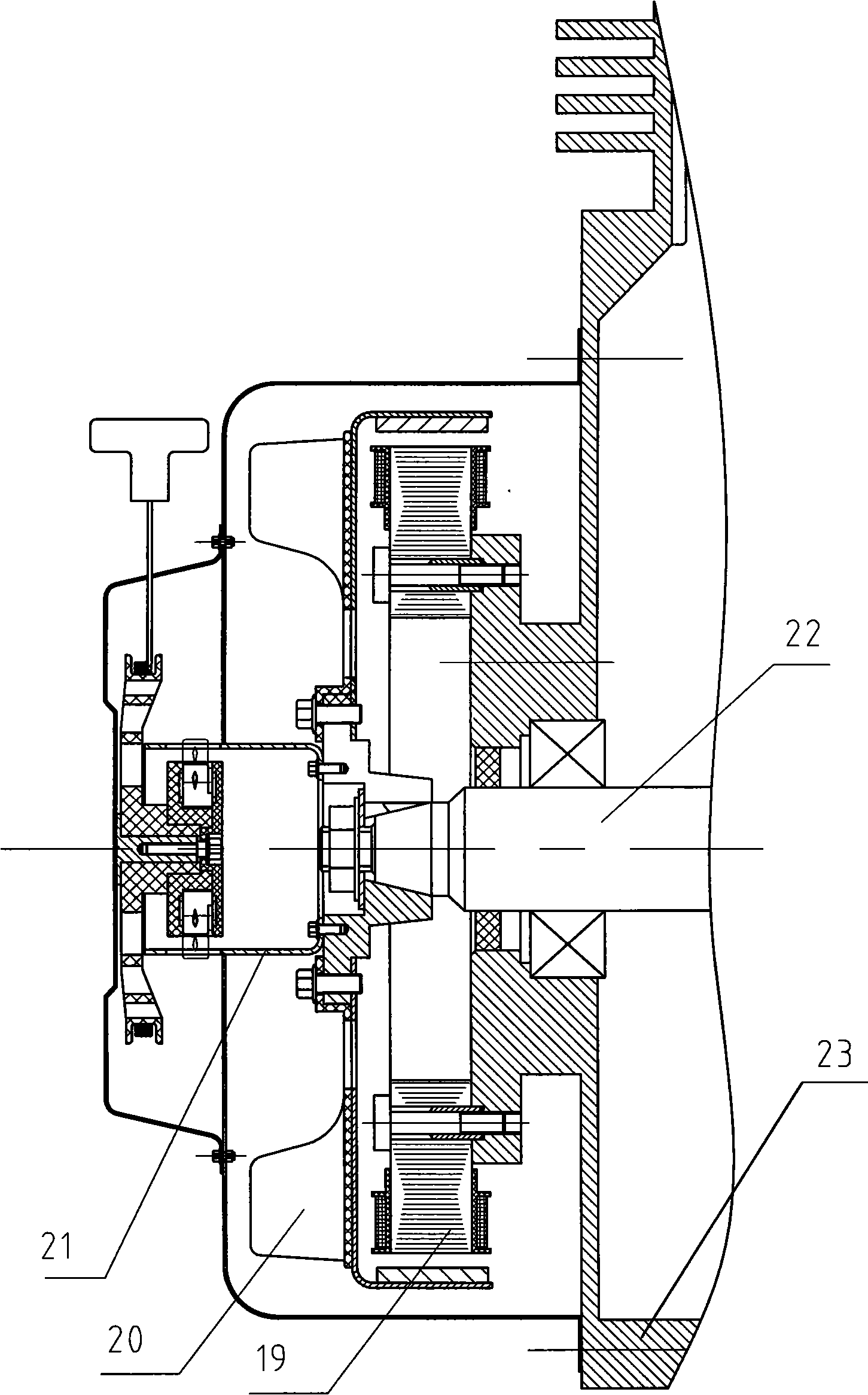

[0012] Such as image 3 As shown, an engine generator, the generator is an inner rotor structure, has a motor, a generator and a starter for starting the engine, the generator and the starter are arranged outside the crankcase of the engine and are coaxially located in the axial direction of the crankshaft On the same side of the engine crankshaft protruding from the crankcase, a flywheel is installed at one end of the crankshaft. The generator is located between the starter and the flywheel. The generator is an inner rotor structure. The generator rotor 1 is supported on the rotor shaft 2 detachably connected to the flywheel 4. Above; the iron core of the generator rotor 1 is provided with an axial hole 9 , and the axial hole 9 corresponds to the position of the axially displaceable ratchet 10 on the starter 6 .

[0013] Because generator rotor 1 is separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com