Conveyor chain

A technology of conveying chain and chain link, applied in the field of conveying chain, can solve the problem of high material cost and achieve the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

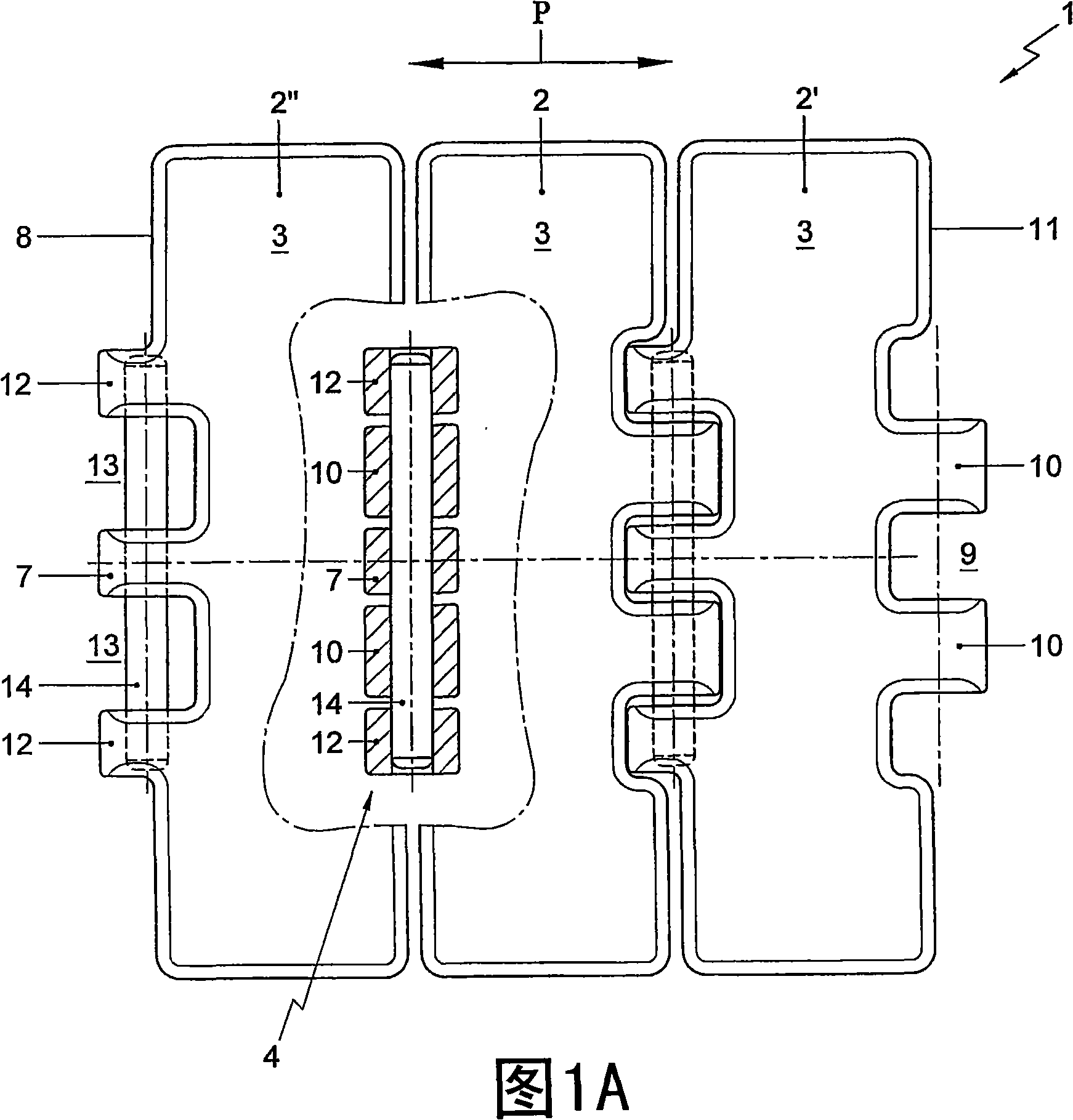

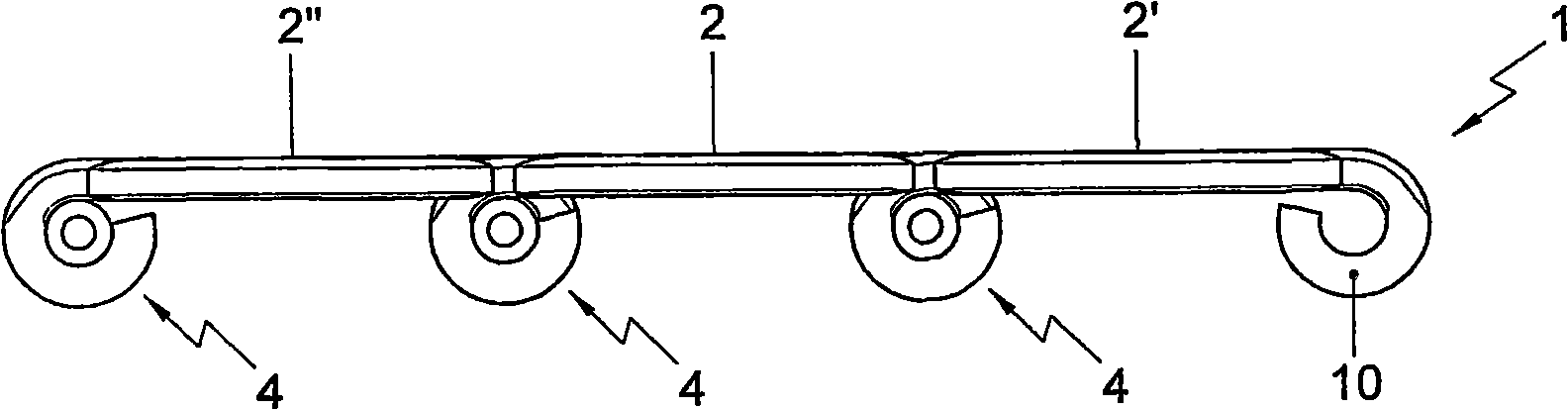

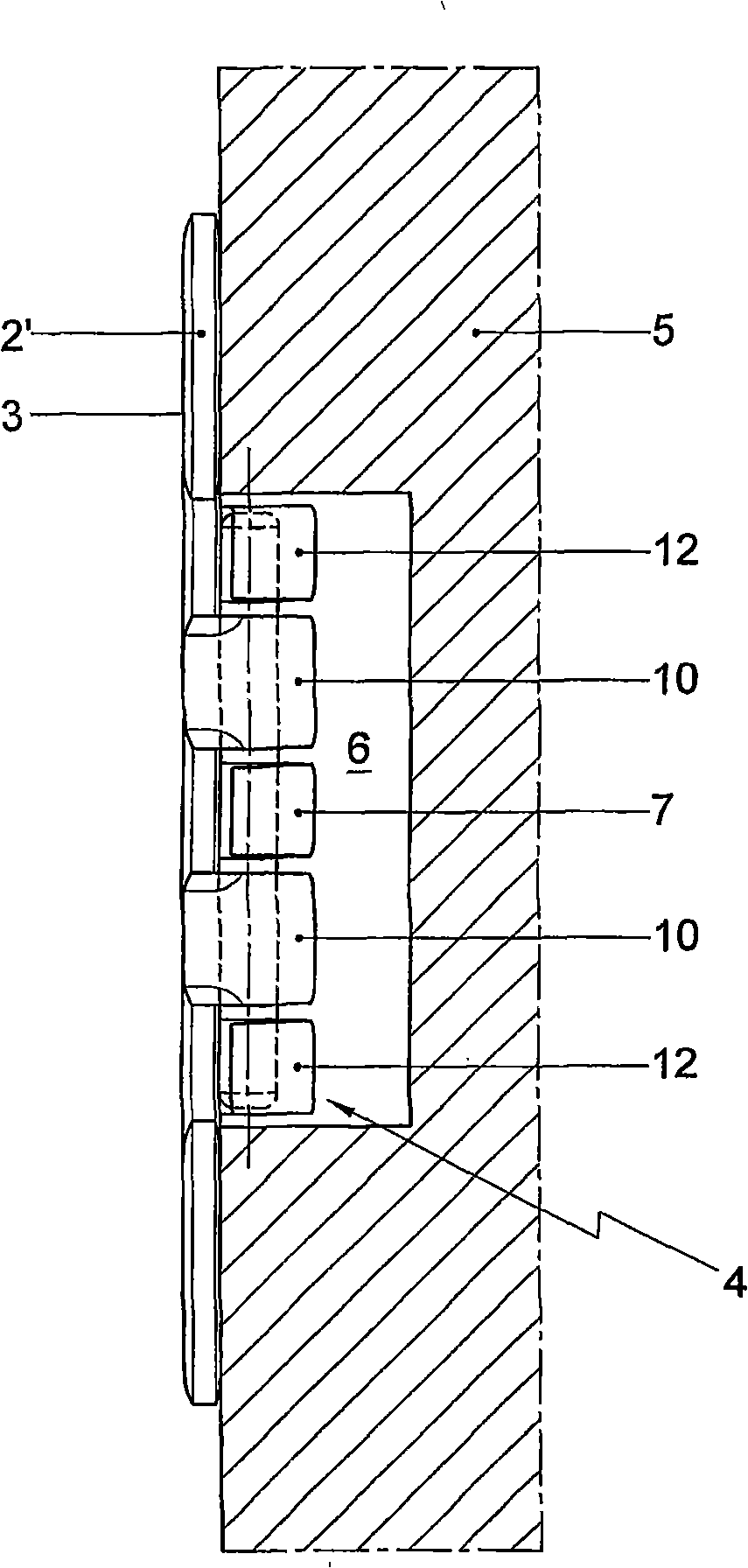

[0023] In these drawings, the same or corresponding parts are denoted by the same reference numerals. These figures are merely schematic representations of preferred embodiments of the invention given by way of non-limiting exemplary embodiments.

[0024] FIG. 1 shows a conveyor chain 1 comprising a series of sheet metal links 2 . Each chain link 2 is respectively provided with a substantially rectangular transmission body part 3 and a hinge assembly 4 located below the transmission body part 3 . In use, the conveyor chain 1 is intended to move along the conveyor track 5 in the conveying direction indicated by the arrow P. The transfer rail 5 supports the transfer body part 3 and is provided with a groove 6 for guiding the hinge assembly 4 therein.

[0025] The sheet metal links are stamped from sheet metal in a manner known to those skilled in the art, while forming the articulating ring. In this exemplary embodiment, the chain links are produced from ferritic-pearlitic st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com