On-line determination device of transformation ratio for metallic materials

A metal material, phase change technology, applied in the direction of material magnetic variable, heat treatment equipment, heat treatment process control, etc., can solve the problems of slow response time, poor measurement characteristics, poor precision, etc., to achieve accurate phase change degree, accurate measurement, ensure The effect of online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The features and advantages of the present invention will now be described in detail with reference to the accompanying drawings in order to understand the above objects.

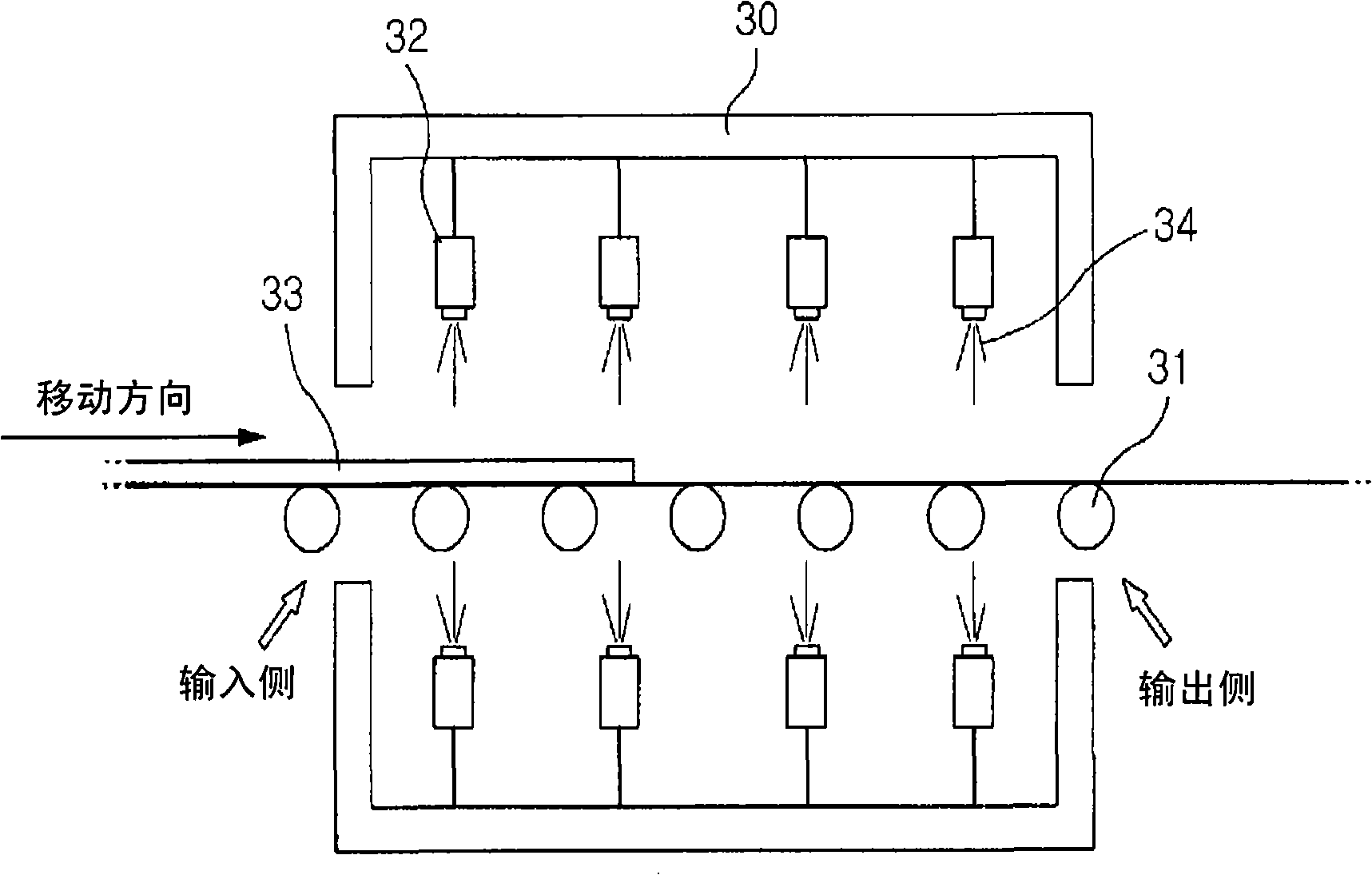

[0053] Figure 4 is a graph showing phase transition and magnetic characteristic change during cooling heat treatment according to the present invention. As described above, when a hot-rolled metal material such as a strip enters a cooling heat treatment process (for example, ROT and ACC), the cooling unit sprays a predetermined amount of cooling water onto the top and bottom surfaces of the metal strip, thereby, The metal strip is cooled. After the austenitic metal strip is hot rolled, it is transported at high speed to the cooling heat treatment process. During the cooling heat treatment, the austenitic metal strip is cooled and exported as ferrite.

[0054] refer to Figure 4 , the metal strip just after hot rolling has a temperature of about 750° C. to 800° C. (see point (a)). At point (a), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com