Overhead crane

A crane and bridge technology, applied in the direction of cranes, trolley cranes, hoisting devices, etc., can solve the problems of low production efficiency, waste of manpower and material resources, etc., and achieve the effect of improving production efficiency, reducing production links, and reducing product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

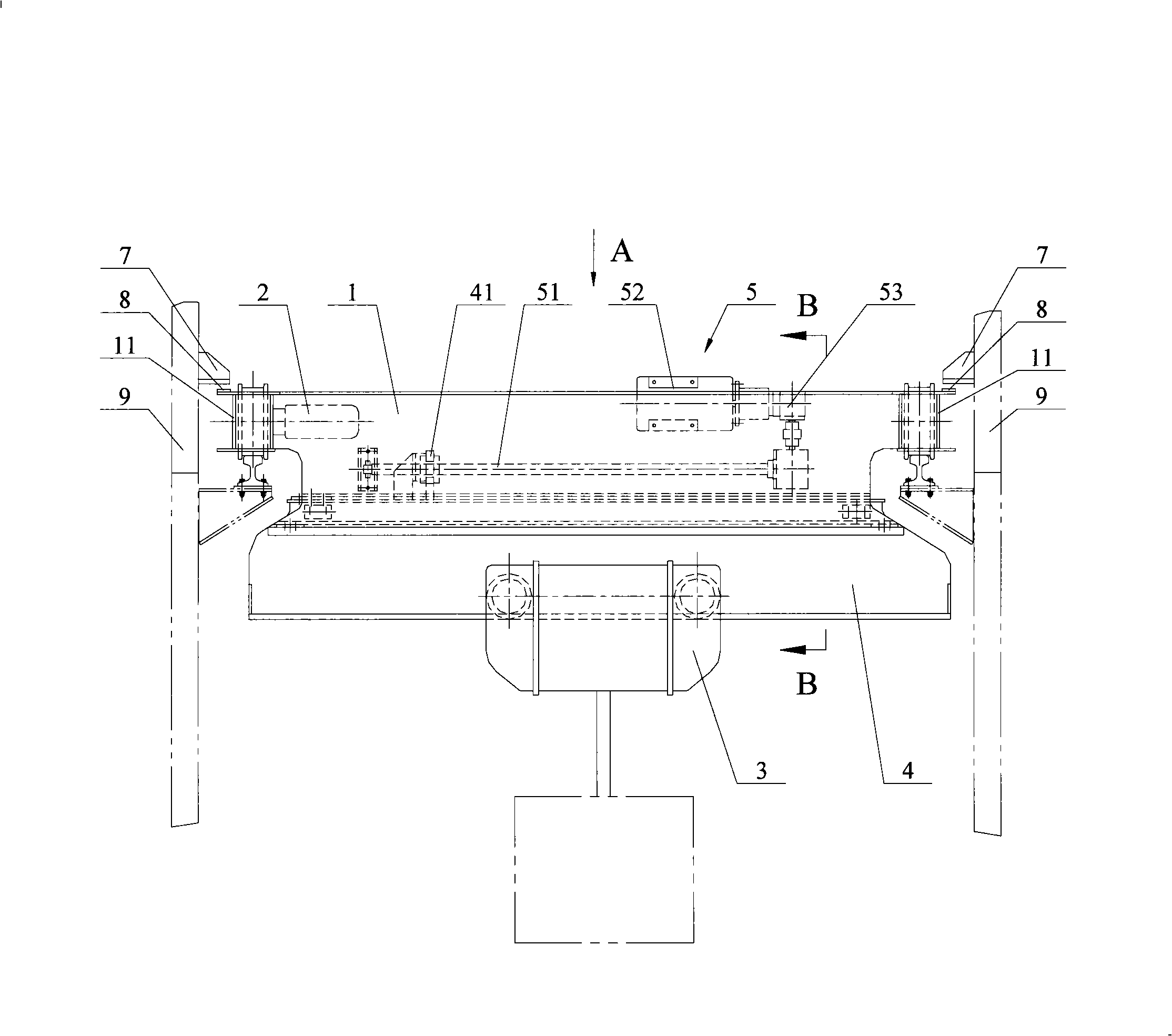

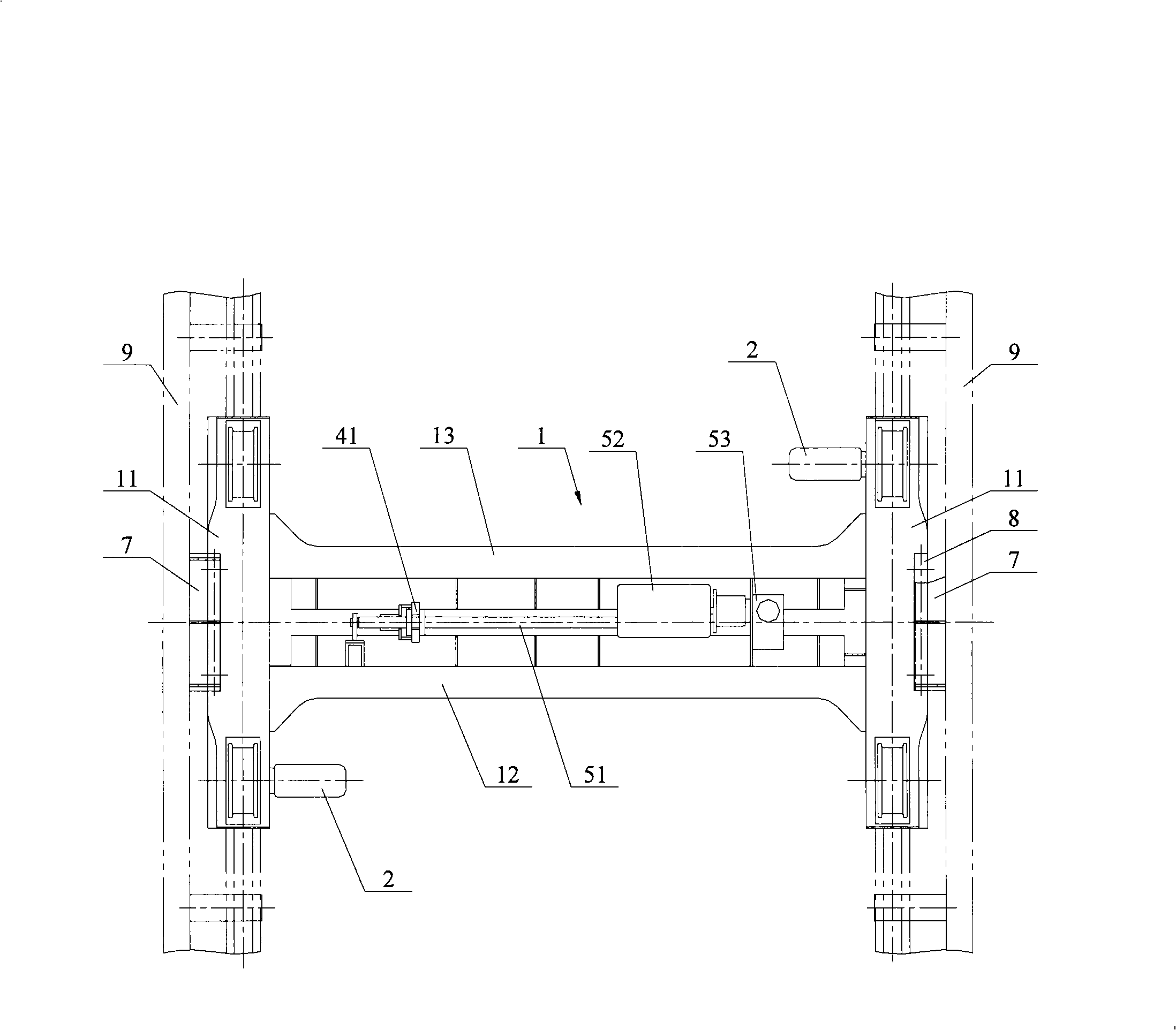

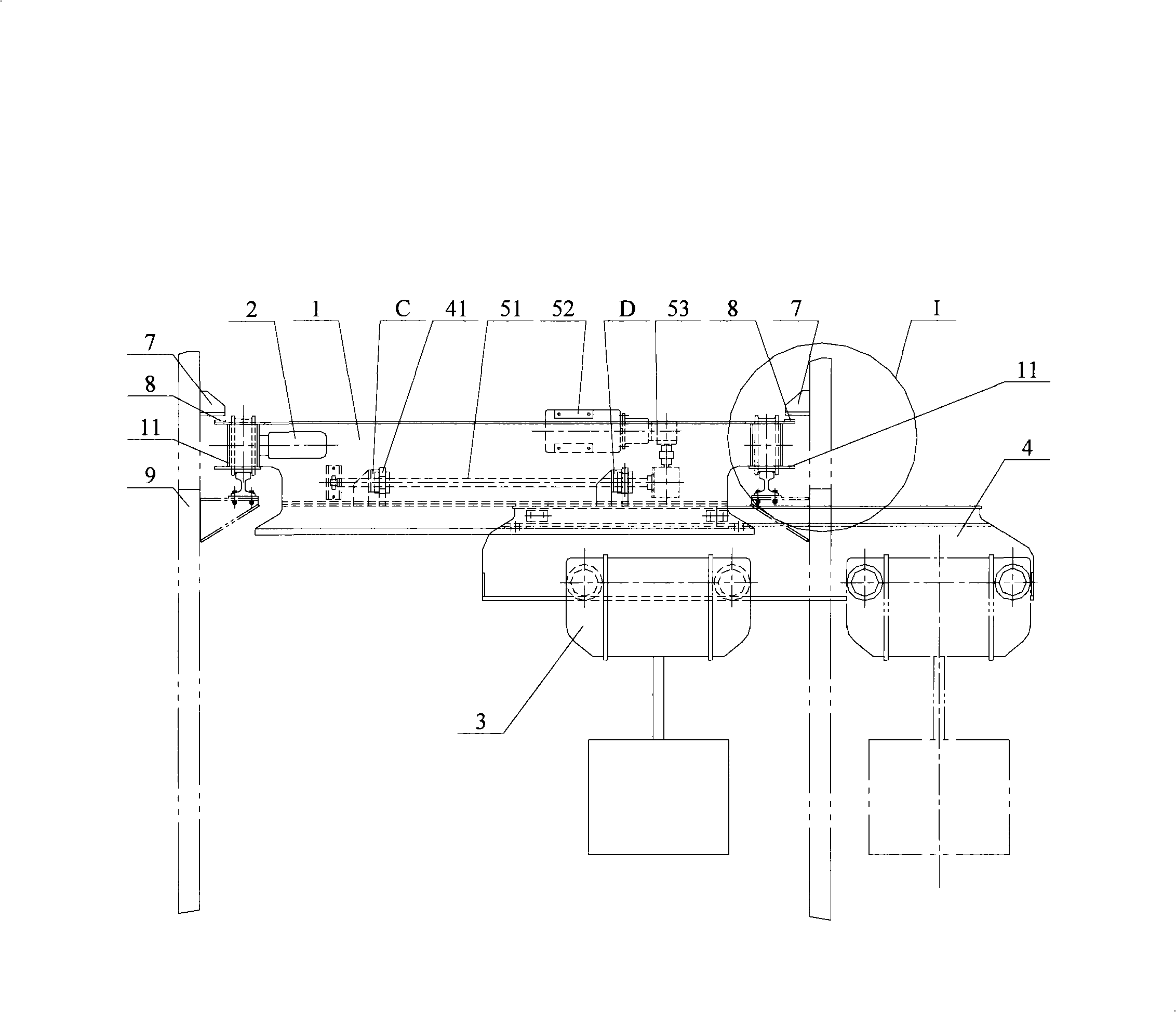

[0031] See figure 1 and figure 2 , figure 1 It is a schematic diagram of the overall structure of the bridge crane of the present invention, figure 2 Yes figure 1 A view from direction A.

[0032] like figure 1 and figure 2 As shown, the bridge crane described in this embodiment is mainly composed of a bridge 1 , a bridge running mechanism 2 , a lifting trolley 3 , a telescopic arm 4 and a telescoping running mechanism 5 .

[0033] Wherein, the bridge running mechanism 2 drives the bridge 1 to run longitudinally along the tracks on the elevated beams 9 on both sides; the lifting trolley 3 runs transversely along the tracks on the bridge 1; the telescopic arm 4 is arranged on Between the lifting trolley 3 and the bridge 1, the lifting trolley 3 runs laterally along the track on the telescopic arm 4; the telescopic running mechanism 5 drives the telescopic a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap