Hydrolyzing method for preparing titanium white

A technology of titanium dioxide and titanium seed crystal liquid, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of wide particle size distribution and uneven particle size, and achieve a narrow particle size distribution, uniform dispersion, and uniform composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

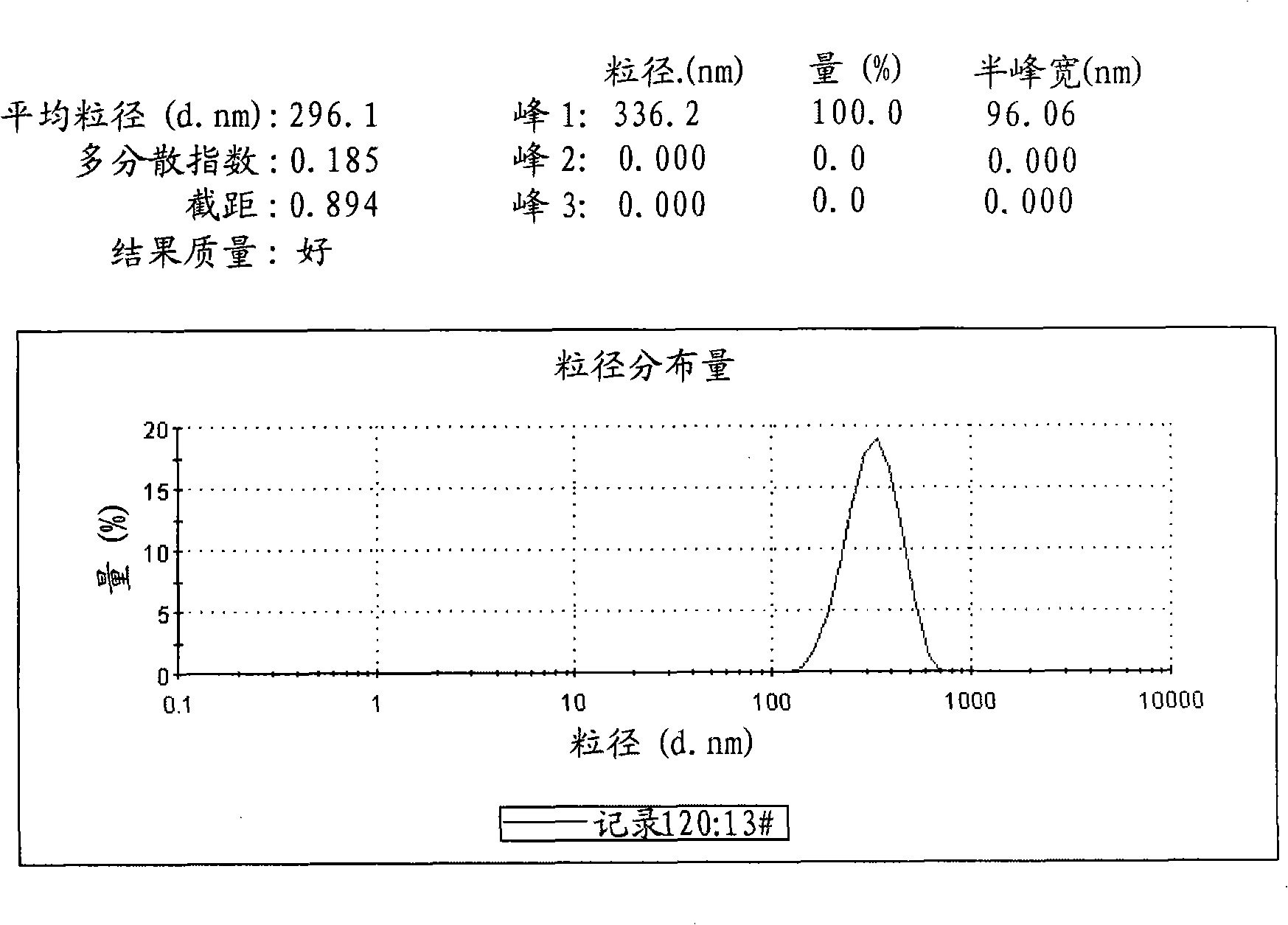

[0025] First heat the deionized water as the bottom water to boiling, then add the deionized water with a volume of 100ml in the boiling state into the hydrolysis pot, stir and maintain a slight boiling state. Take 5ml of seed crystal titanium solution and add it to the above boiling bottom water to form a hydrolysis system. The pH value of the system is 2.5. Keep the system slightly boiling, and carry out the first aging for 5min under stirring. As the aging progresses, the colloidal Ti(OH) 4 first converted to TiO 2+ ions, followed by thermal hydrolysis to generate stable and uniform TiO(OH) 2 Seed crystals, to avoid some of the seeds cannot make TiO due to high acidity 2+ Converted to TiO(OH) 2 , leading to the defect that the number of seed crystals is insufficient. Add 500ml of hydrolyzed titanium solution preheated to 90°C with a concentration of 200g / l into the hydrolysis pot at a constant speed within 15 minutes. During the addition, the temperature of the system w...

Embodiment 2

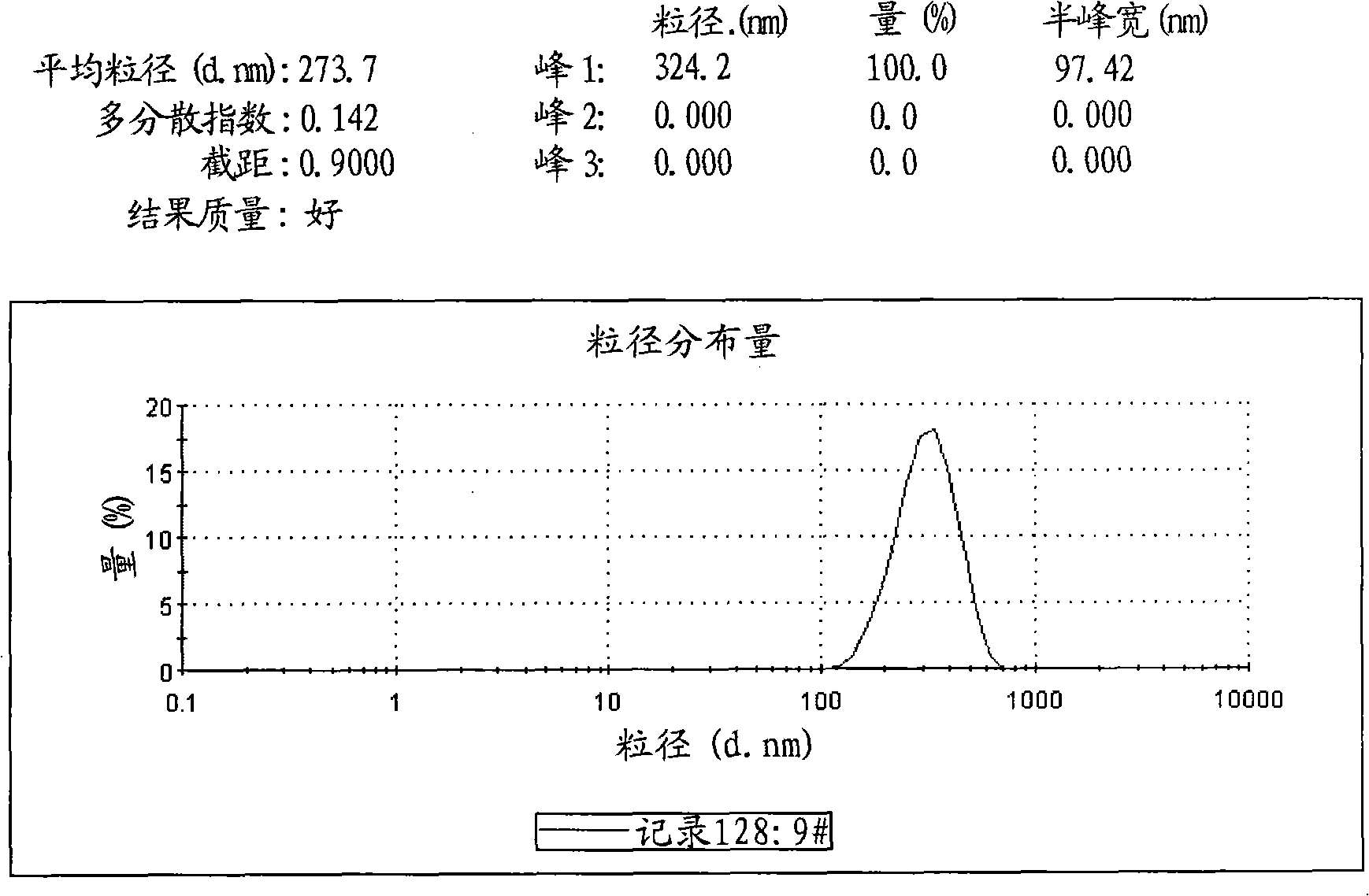

[0028] First heat the deionized water as the bottom water to boiling, then add the deionized water with a boiling volume of 125ml into the hydrolysis pot, stir and maintain a slight boiling state. Take 10ml of seed crystal titanium solution and add it into the boiling bottom water to form a hydrolysis system. The pH value of the system is 2.2. Keep the system slightly boiling, and carry out the first aging for 10 minutes under stirring. As aging proceeds, colloidal titanium hydroxide first transforms into TiO 2+ ions, followed by thermal hydrolysis to generate stable and uniform TiO(OH) 2 Seed crystals, to avoid some of the seeds cannot make TiO due to high acidity 2+ Converted to TiO(OH) 2 , leading to the defect that the number of seed crystals is insufficient. Add 500ml of titanium hydrolysis solution preheated to 93°C with a concentration of 220g / l into the hydrolysis pot at a constant speed within 18 minutes. During the addition, the temperature of the system was main...

Embodiment 3

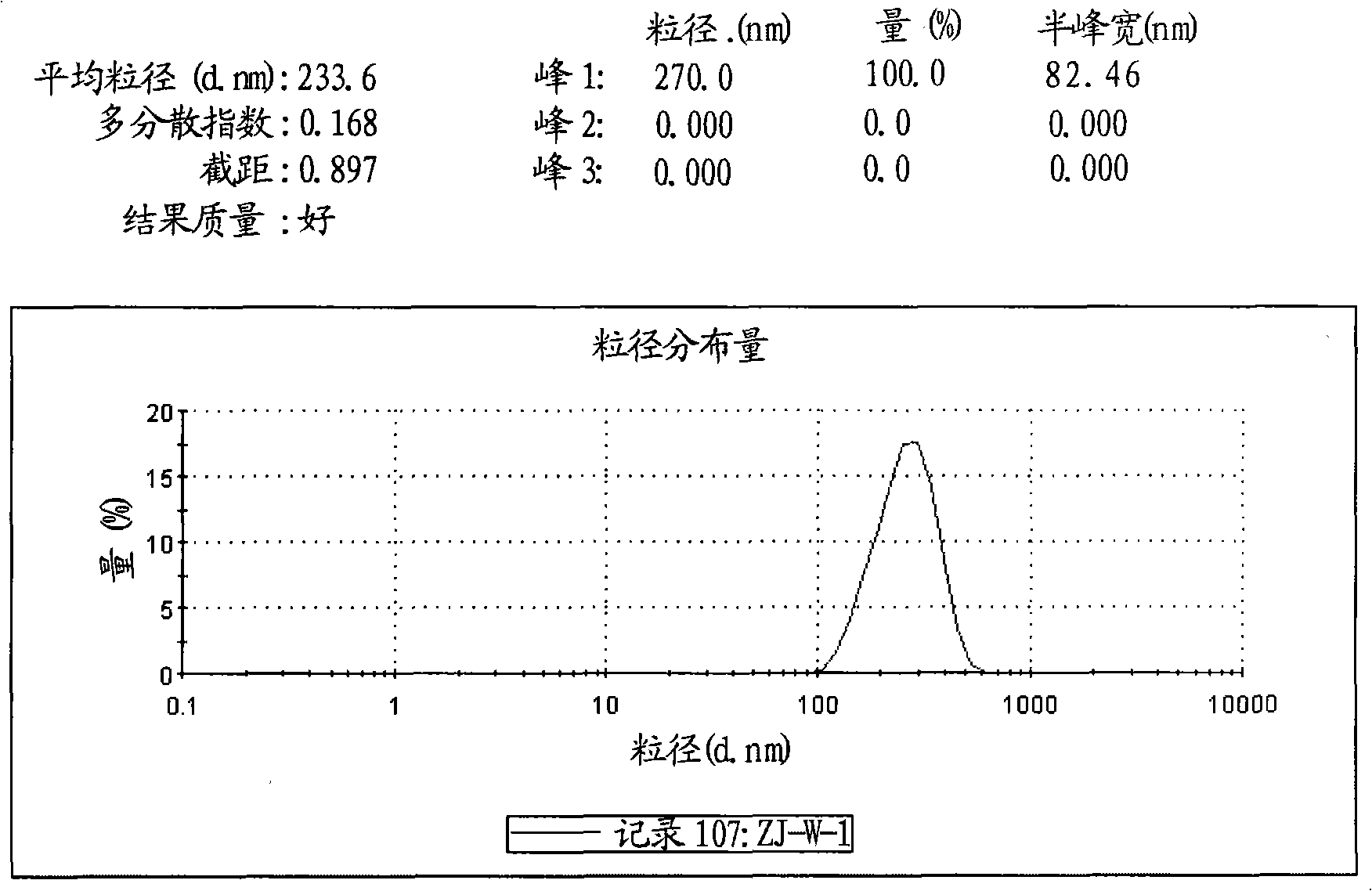

[0031] First heat the deionized water as the bottom water to boiling, then add the deionized water with a boiling volume of 150ml into the hydrolysis pot, stir and maintain a slight boiling state. Take 15ml of seed crystal titanium solution and add it into the boiling bottom water to form a hydrolysis system. The pH value of the system is 2.0. Keep the system slightly boiling, and carry out the first aging for 15 minutes under stirring. As aging proceeds, colloidal titanium hydroxide first transforms into TiO 2+ ions, followed by thermal hydrolysis to generate stable and uniform TiO(OH) 2 Seed crystals, to avoid some of the seeds cannot make TiO due to high acidity 2+ Converted to TiO(OH) 2 , leading to the defect that the number of seed crystals is insufficient. Add 500ml of hydrolyzed titanium solution preheated to 98°C with a concentration of 240g / l into the hydrolysis pot at a constant speed within 20min. During the addition, the temperature of the system was maintaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com