Cleaning method for compact spinning top roller

A compact spinning and cleaning technology, which is applied in spinning machines, textiles and papermaking, and continuous winding spinning machines, etc. It can solve problems such as difficult support, cots and front cots cannot be cleaned at the same time, and it is easy to achieve precision Guaranteed, simple structure, convenient and reliable installation

Inactive Publication Date: 2008-10-15

JIANGNAN UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention mainly solves the problem that it is difficult to clean the top roller of the compact spinning spinning frame by negative pressure suction, and it is difficult to support the suede roller, and the problem that the lead-out rubber roller and the front rubber roller cannot be cleaned at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

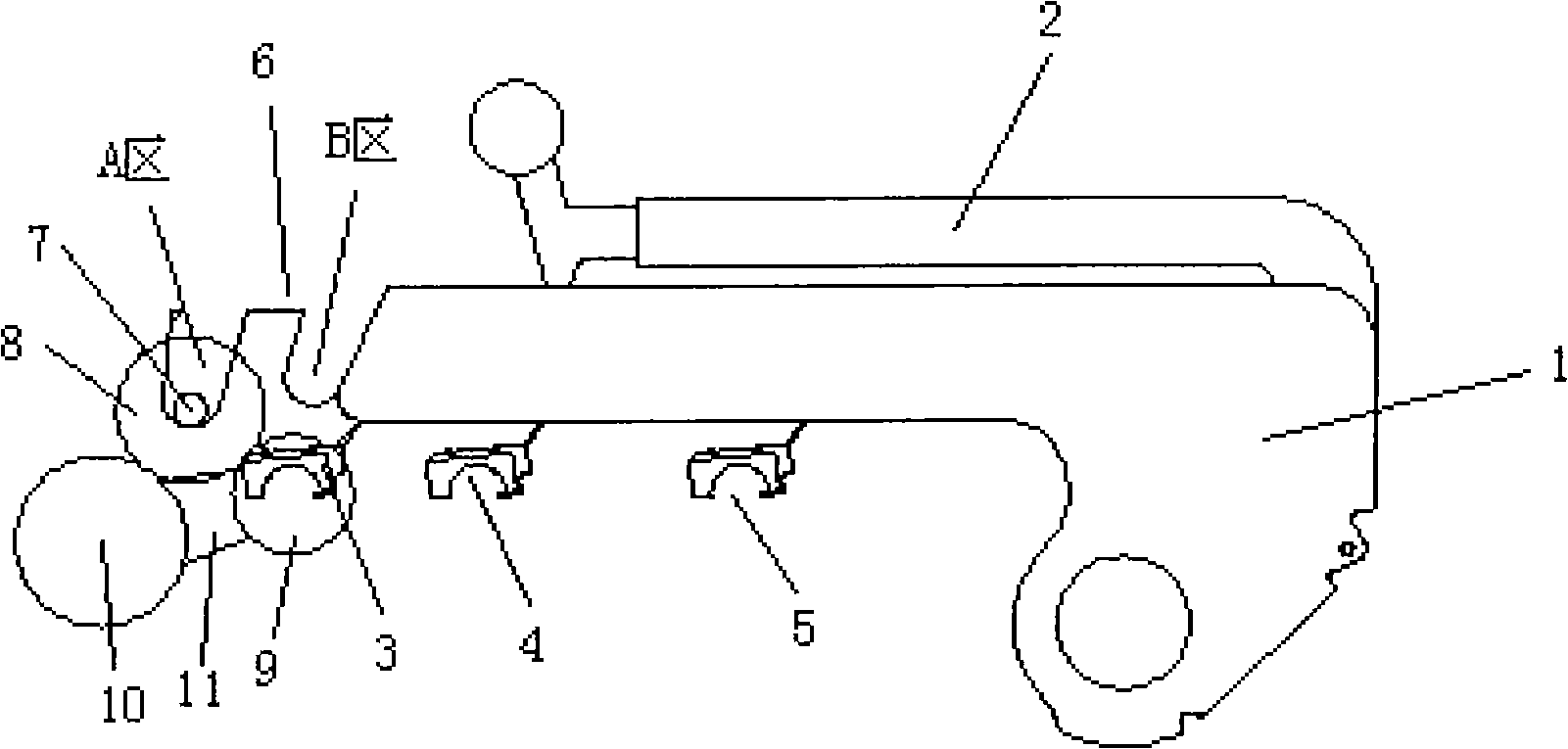

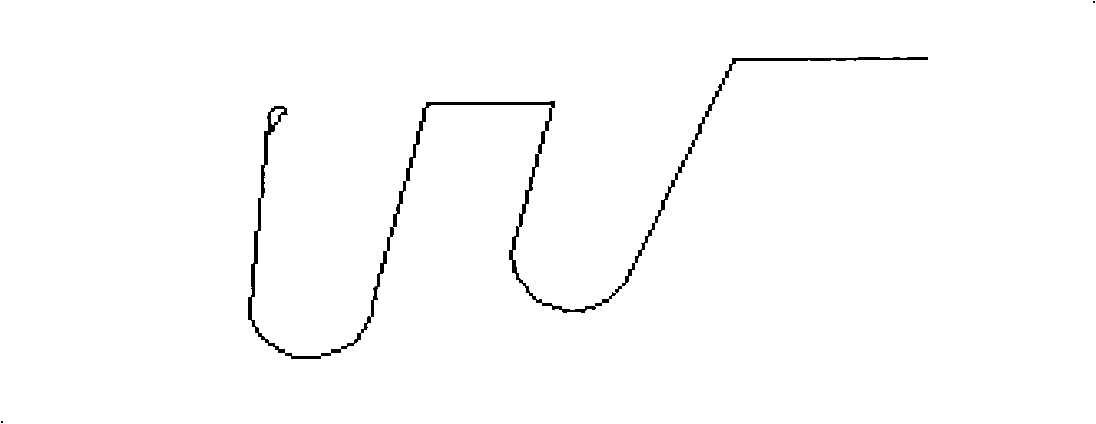

The invention provides a method for cleaning a tight spinning belt roller component, relating to the spinning new technical field, in particular to a novel supporting method only for a clearer spring support [6] under the condition that a cradle body [1], a cradle handle [2], a front collet [3], a middle collet [4] and a rear collet [5] which are arranged originally on a tight spinning frame are not exchanged. The method comprises the following steps that: an added tight spinning cleaning support area comprises a tight area [area A] and a ring spinning area [area B]; at the same time, a clearer roller axle [7] can be adjusted freely in the two areas; and the clearer spring support [6] not only satisfies the support to a ring spinning cleaning clearer roller [8], but also satisfies a function of supporting the ring spinning cleaning clearer roller [8]. The method also has the advantages that when the clearer spring support [6] is arranged in the tight area, a tight spinning front rubber roll [9] can not only be cleaned by the clearer spring support [6]; at the same time, a yarn leading rubber roll [10] of a tight spinning belt roller component [11] also can be cleaned by the clearer spring support [6], thereby keeping the cleaning of the surface of the front rubber roll [9], also protecting the cleaning of the surface of the leading-out rubber roll [10] so as to prolong the service life of the leading-out rubber roll [10], further improve the service life of a grid ring of the tight spinning key part, save the cost for a spinning mill and improve the labor efficiency. Additionally, the clearer spring support [6] can be switched conveniently in the tight spinning and the ring spinning, even if the tight spinning is switched into the ring spinning, the cleaning of the front rubber roll [9] can also be carried out without exchanging, thereby having the advantages of saving time, labor and reducing labor intensity of workers.

Description

A cleaning method for compact spinning cot roller assembly technical field The present invention relates to the field of spinning new technology, specifically, when the traditional ring spinning frame is transformed into compact spinning technology, under the condition that the original cradle components on the spinning frame are not replaced, the top roller assembly is cleaned. The roller spring support seat adopts a new type of support method, that is, a compact spinning support area is added, so that the spring support seat of the cleaning pile roller can be directly fixed on the cradle, and can play the function of supporting the cleaning pile roller; it can be cleaned at the same time The front top roller and yarn delivery top roller of the top roller box assembly; in addition, the top roller assembly can be easily installed, and can be freely switched between compact spinning and ring spinning. Background technique Compact spinning technology is a new type of spinnin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): D01H5/60D01H5/56D01H1/14

Inventor 徐伯俊魏国谢春萍苏旭中潘鲲鹏许厚华苗广潮金玉斌

Owner JIANGNAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap