Boosting pump for steering car

A technology for power steering pumps and automobiles, which is applied to pump components, rotary piston type/swing piston type pump components, components of pumping devices for elastic fluid, etc., which can solve the problem of low output power of the engine at idle and no settings Problems such as pressure switch and easy flameout of the engine can prevent the phenomenon of cavitation and insufficient oil absorption, eliminate the effect that the flow rate cannot be reduced, and the pressure pulse is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

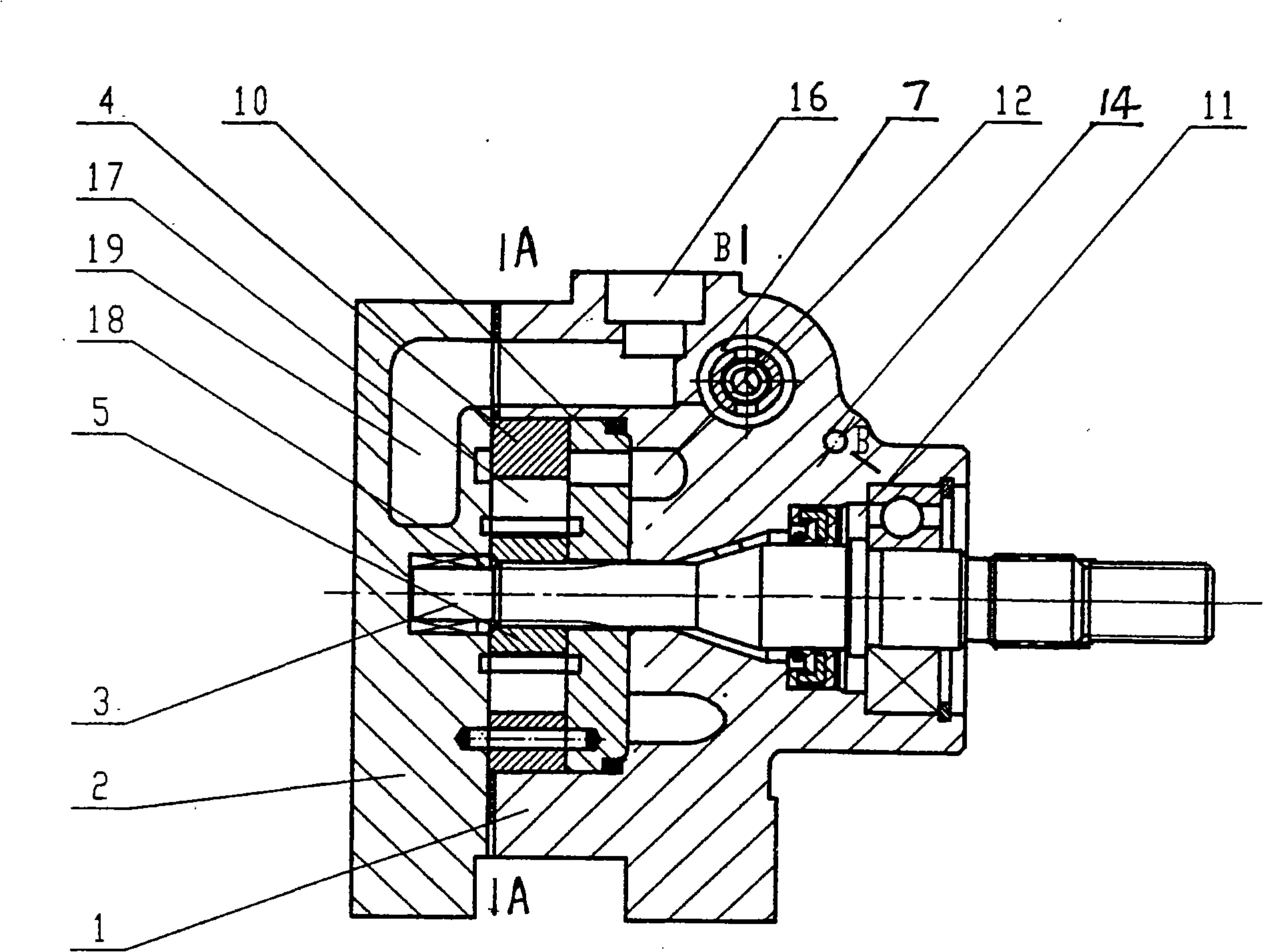

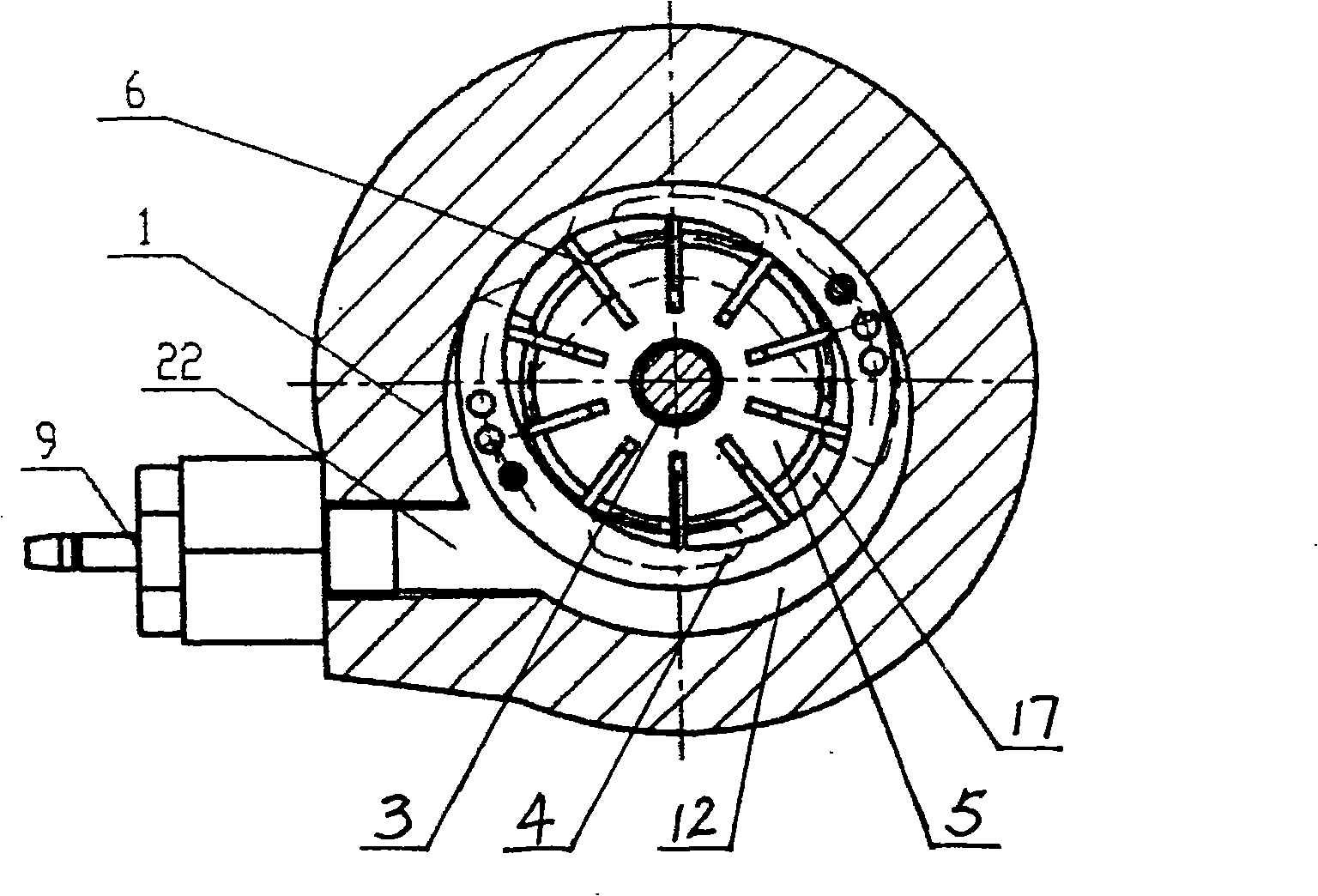

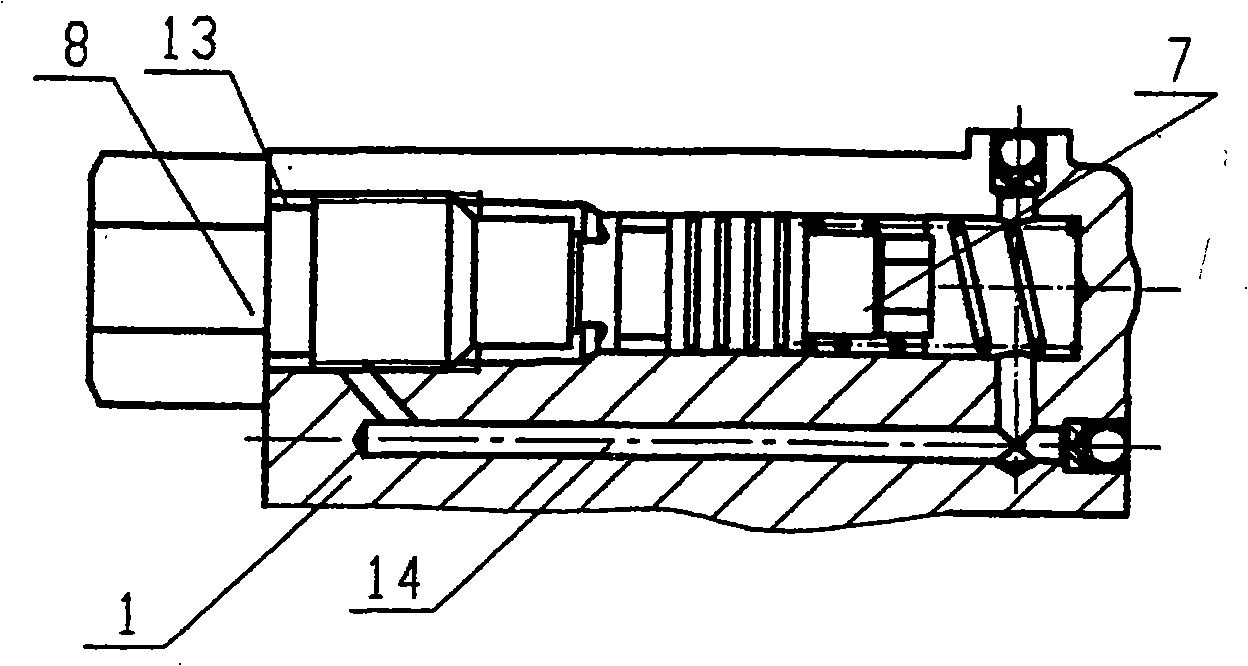

[0026] When working, the engine transmits the torque to the pump shaft 3, driven by the pump shaft 3, the rotor 5 placed in the compression chamber 17 rotates, and the blade 6 inserted in the groove of the rotor 5 is thrown out by centrifugal force and moves along the compression chamber 17. The compression chamber wall slides. Through the oil inlet hole 16 and the oil suction window 27 on the oil distribution plate 10 (angle θ 1 ), the oil in the steering oil pot is sucked into the compression chamber 17 through the oil inlet hole 16 through the oil chamber 19, and then passes through the oil pressure window 28 on the oil distribution plate 10 (angle θ 2 ) hydraulically enters the pump chamber 12, and enters the oil outlet nozzle 8 through the oil introduction hole 14 and the oil outlet hole 13, and the flow is controlled by the throttle body 20 and the slide valve 21 to output to the steering gear within the control flow range of the automobile power steering pump . When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com