Method for measuring rotating shaft deflection

A technology of rotating shaft and maximum deflection, applied in the field of measurement, it can solve the problems of troublesome measurement, rotor falling, bearing seat emptying, etc., and achieve the effect of simple test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

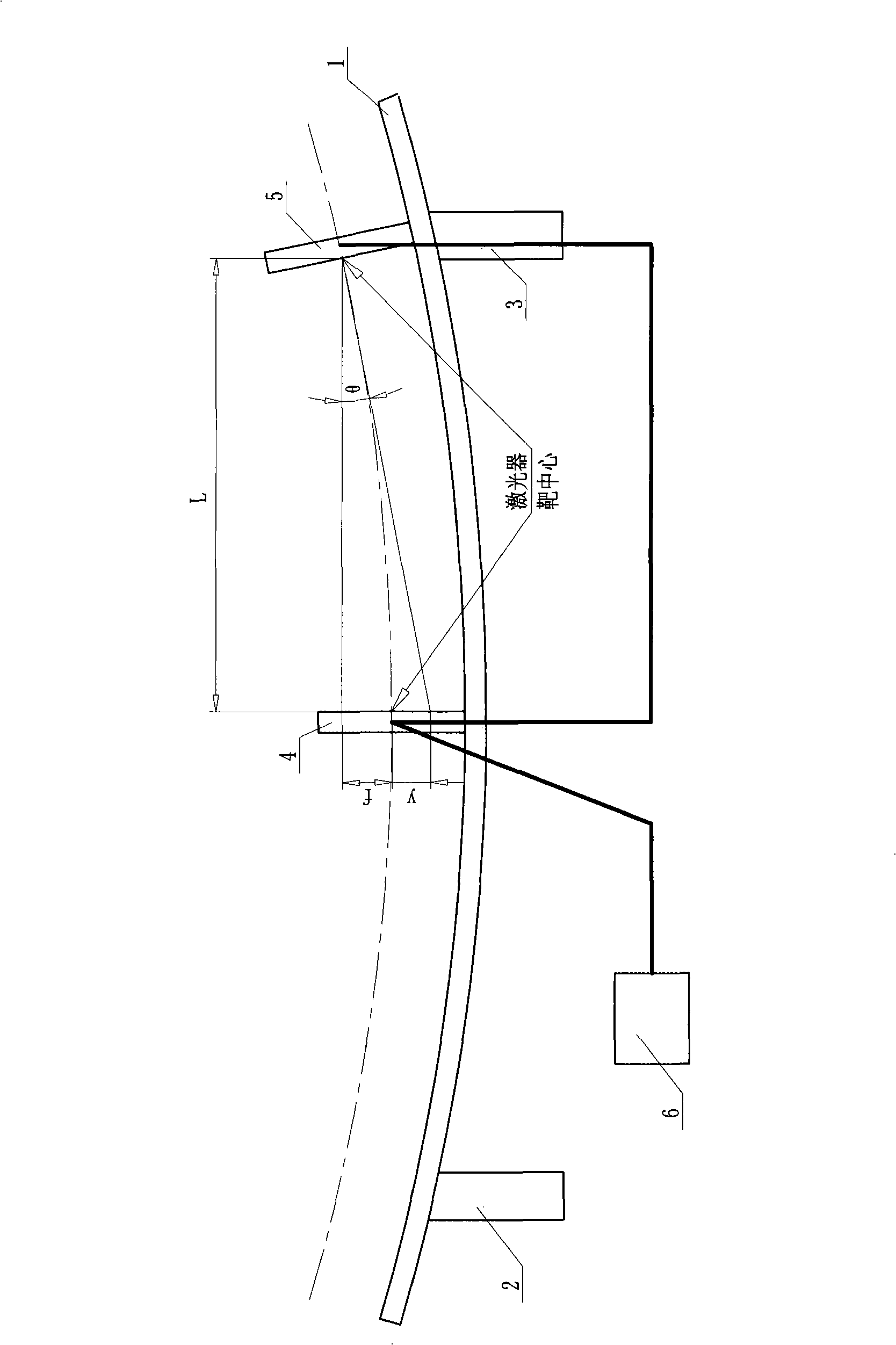

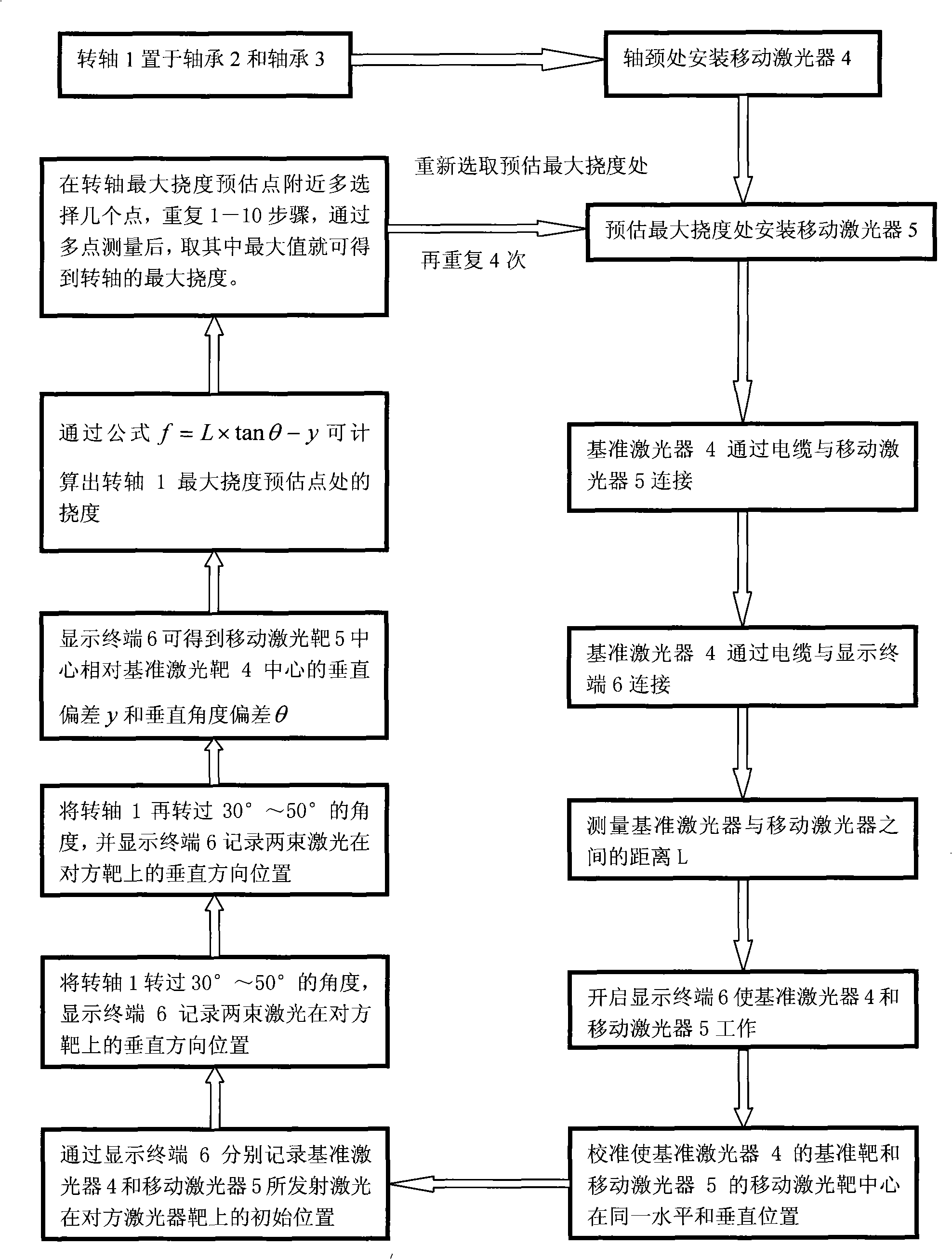

[0030] Such as figure 2 As shown, it is a schematic diagram of a method for measuring the deflection of the rotating shaft, and a method for measuring the deflection of the rotating shaft is:

[0031] The first step. supporting the first bearing 2 and the second bearing 3 at both ends of the rotating shaft 1;

[0032] The second step. Install the mobile laser 5 at the journal of the rotating shaft 1, install the reference laser 4 at the estimated point of maximum deflection of the rotating shaft, the reference laser 4 is connected with the mobile laser 5 through a cable, and the reference laser 4 is connected with the display terminal 6 through a cable, And measure the distance L=680mm between the reference laser 4 and the moving laser 5, the reference laser 4, the moving laser 5 and the display terminal 6 are all outsourced;

[0033] The 3rd step. assembly language programming, run on the display terminal 6;

[0034] Step 4. Turn on the power supply of the display terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com