Boot for universal joint

A universal coupling and dust cover technology, applied in the field of dust cover, can solve the problems of increased contact surface pressure, increased operating torque, wear, etc., to reduce rotational resistance, inhibit the increase of contact force, The effect of reducing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

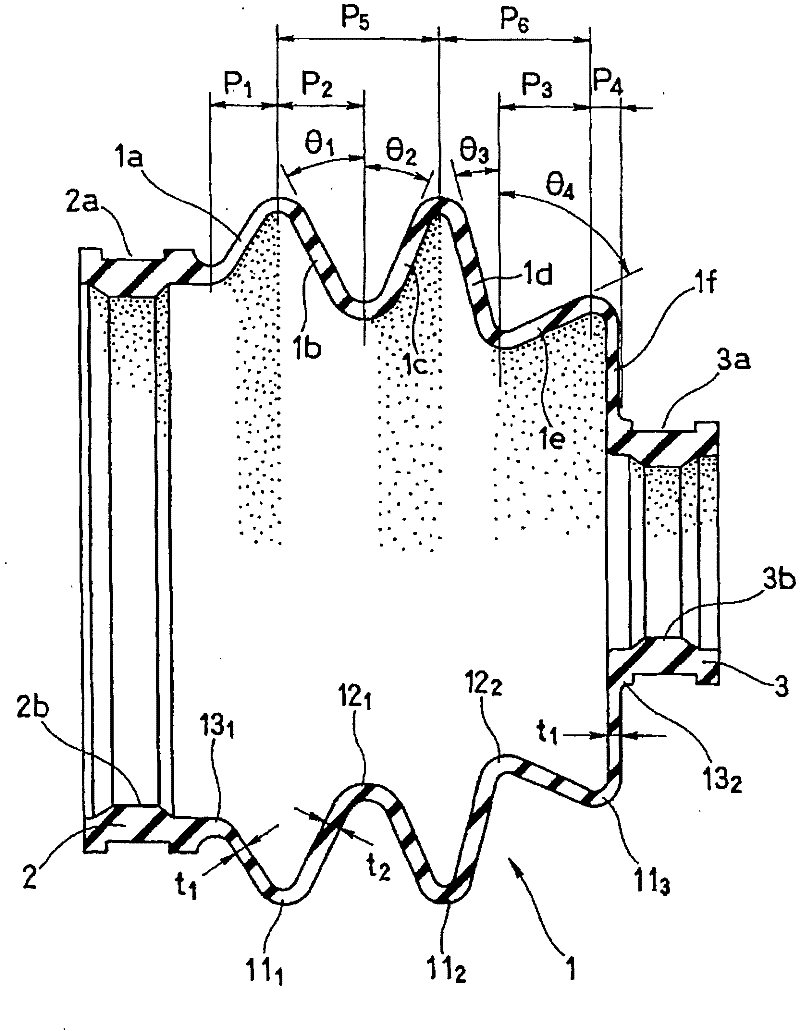

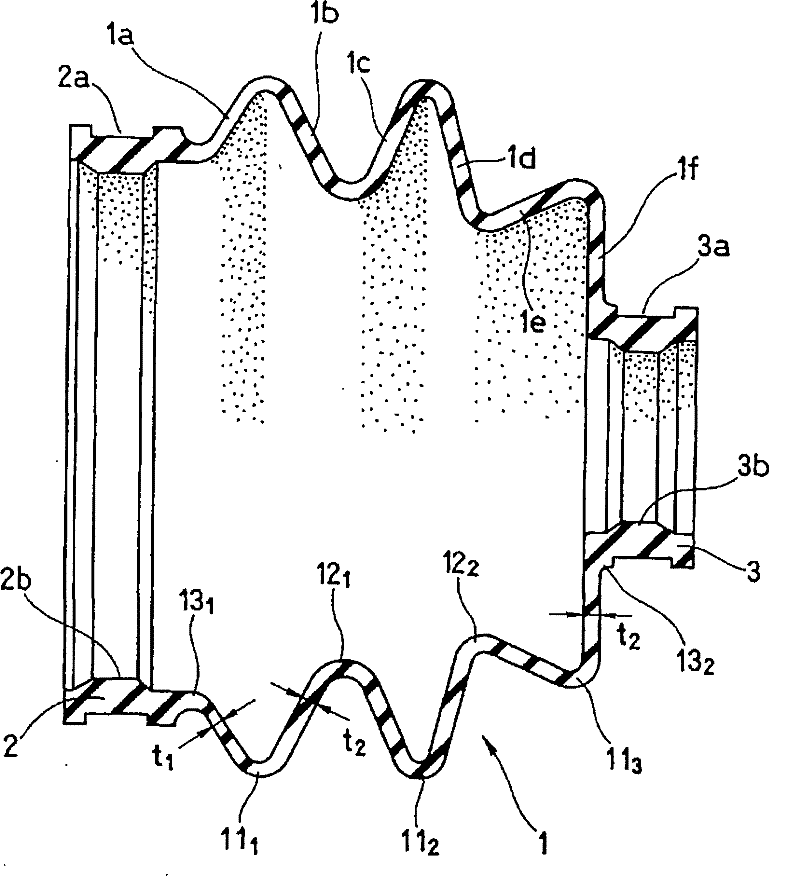

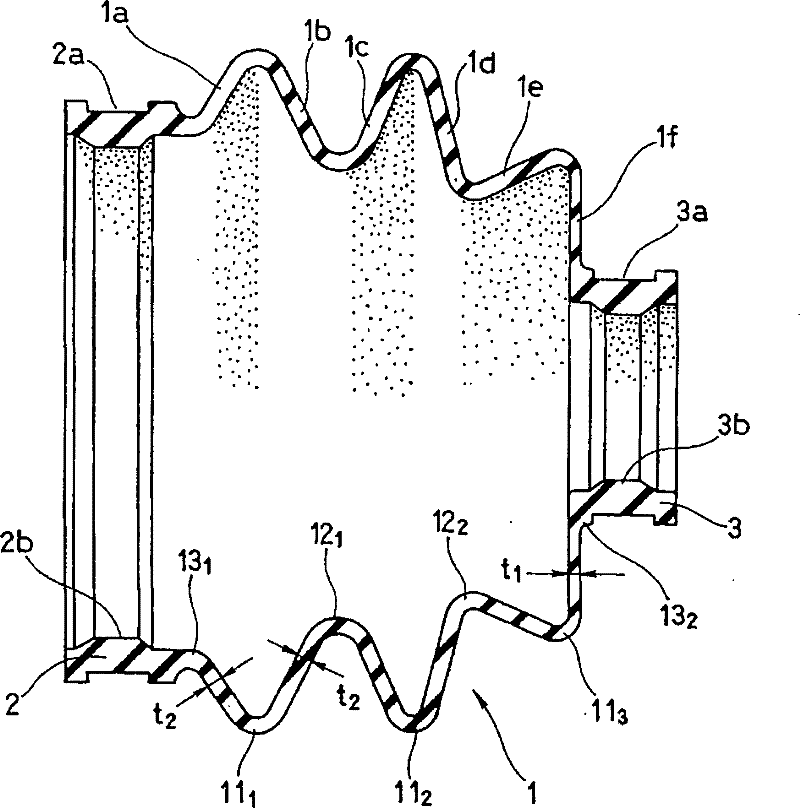

[0054] Table 1 represents the pair with figure 1 The dustproof cover and installation shape, installation size and set length of the embodiment of the present invention with the same structure shown are all the same as this embodiment, but the wall thickness of the bellows part 1 is uniform (all are t 2 ) and θ 1 = θ 2 , θ 3 = θ 4 Compared with the dust boots of the comparative example, when the coupling angle increases, the valley portion 12 on the side where the bellows part 1 is compressed 1 Between the sides and in the valley 12 2 The result of the angle at which contact begins between the two sides. It can be seen from Table 1 that the dust cover according to the present invention greatly delays the timing at which the compression side starts to contact.

[0055] Table 1

[0056]

[0057] Figure 4 is denoted by FEM derivation of the coupling angle with valley 12 1 The result of the contact force relationship between the two sides is an explanatory diagram co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com