Manufacturing method of linear wheel frame

A manufacturing method and inline wheel technology, which are applied to roller skates, skateboards, skating, etc., can solve the problems of wasting materials, increasing manufacturing costs, and consuming processing time.

Inactive Publication Date: 2008-10-22

万丰州

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

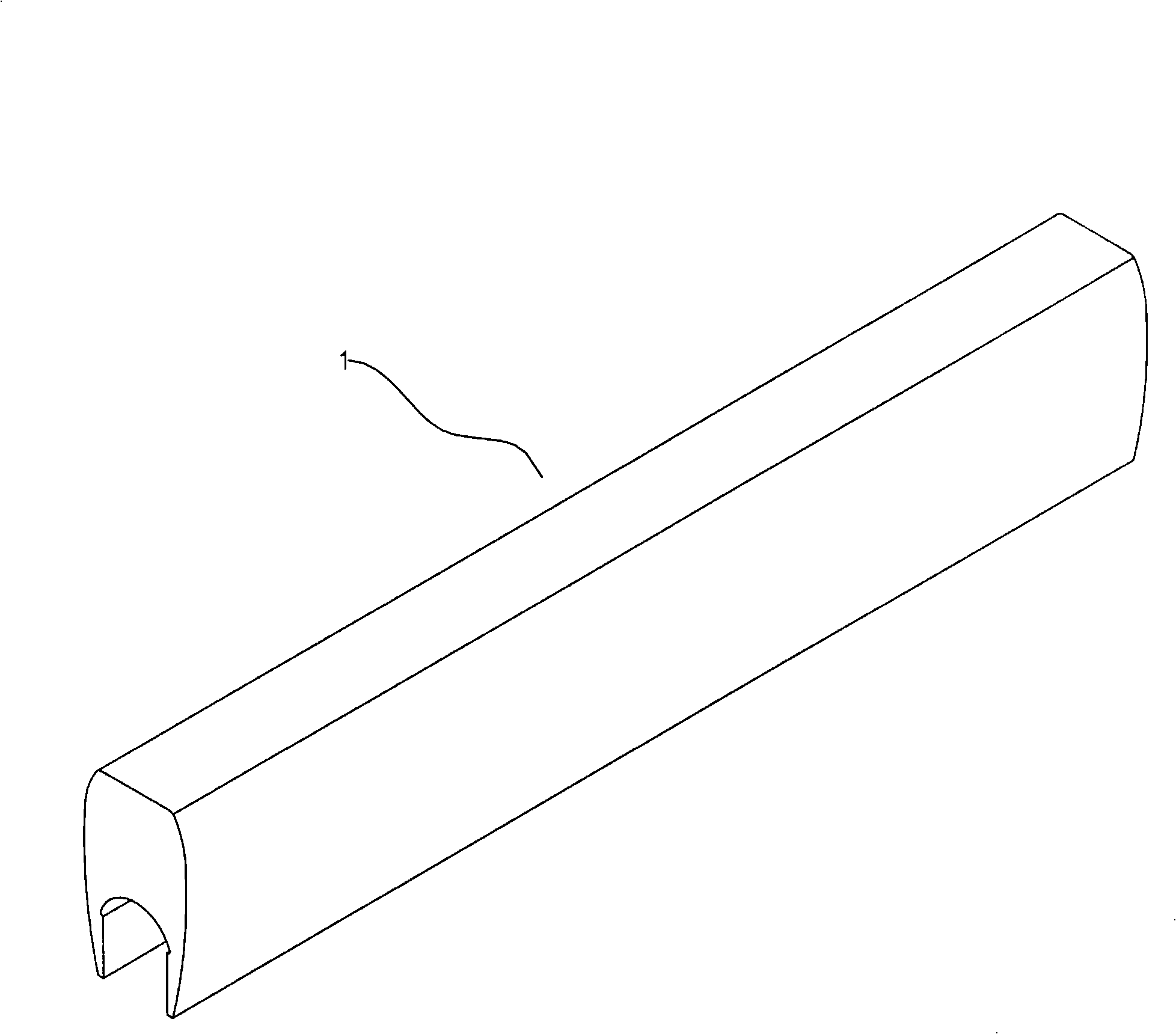

Referring to Fig. 1, the existing in-line wheel frame manufacturing method is to use nearly solid raw materials, and then use a central cutting machine (CNC) to cut out the shape and holes required by the frame, which not only wastes a large amount of material, but also consumes Quite a lot of processing time, not only prone to defective products, but also relatively high manufacturing costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

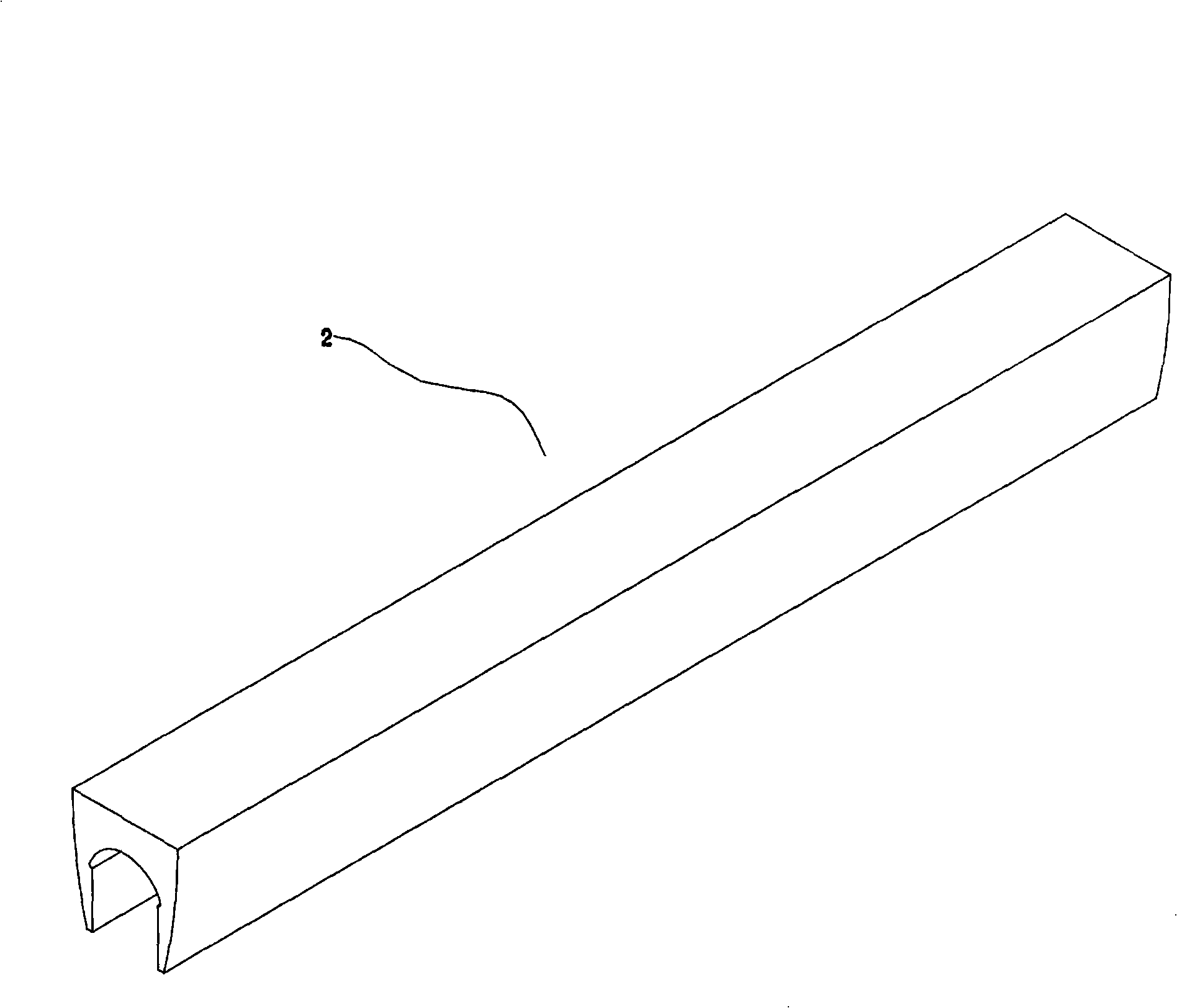

The invention provides a method for manufacturing a direct discharging wheel frame, which is mainly characterized in that raw material is firstly forged as the outline appearance of the frame; the shape and holes required by the frame are then cut by a central cutting machine (CNC), thus shortening the cutting process time, improving the production speed of the finished product, reducing the cost of the material, increasing the strength and achieving lightweight.

Description

Manufacturing method of inline wheel frame technical field The invention relates to a manufacturing method of an in-line wheel frame, which mainly forges raw materials into a rough shape of the frame by forging, and then cuts out the shape and holes required by the frame with a central cutting machine (CNC). Thereby shortening the cutting processing time, increasing the production speed of finished products and reducing the cost of materials, and increasing the strength to achieve light weight. Background technique Referring to Fig. 1, the existing in-line wheel frame manufacturing method is to use nearly solid raw materials, and then use a central cutting machine (CNC) to cut out the shape and holes required by the frame, which not only wastes a large amount of material, but also consumes Quite a lot of processing time, not only prone to defective products, but also relatively high manufacturing costs. Contents of the invention In the manufacturing method of the in-li...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A63C17/06

Inventor 万丰州

Owner 万丰州

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com